Road cushion layer

A road cushion and surface layer technology, which is applied to roads, roads, road construction reinforcements, etc., can solve the problems of affecting the overall bearing strength, high garbage removal costs, and poor use effects, so as to reduce foreign transportation and reduce waste. Lower construction cost and better use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

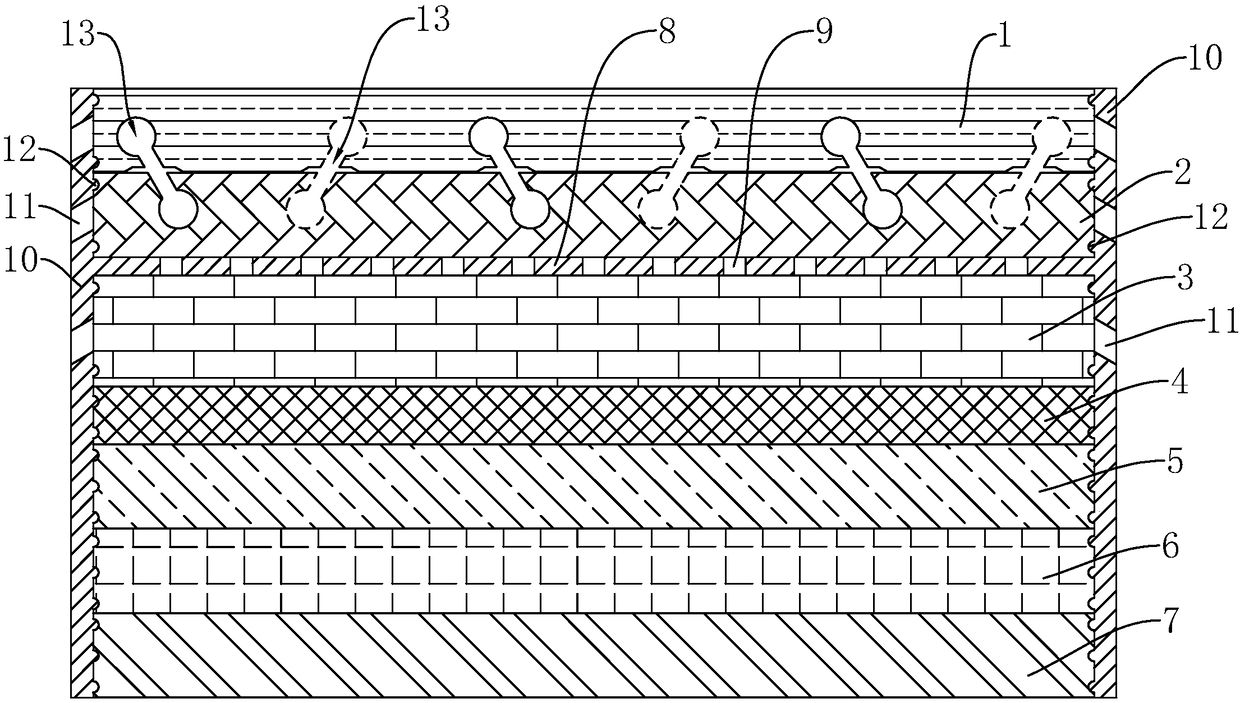

[0032] A road cushion disclosed in this embodiment, such as figure 1 As shown, it includes a concrete mortar surface layer 1, a steel fiber concrete layer 2, a water seepage layer 3, a mesh layer 4, a waterproof layer 5, a soil base layer 6, and a construction waste road cushion layer 7 arranged sequentially from top to bottom. Both the layer 1 and the steel fiber concrete layer 2 are provided with seepage gaps communicating with the water seepage layer 3 , and the soil base 6 is seamlessly laid on the lower surface of the waterproof layer 5 .

[0033] Wherein, the thickness of the concrete mortar surface layer 1 is smaller than the thickness of the steel fiber concrete layer 2 . And the thickness of the soil base 6 is greater than the thickness of the water seepage layer 3 . The construction waste road cushion 7 includes crushed construction waste fragments laid under the soil base 6, and the maximum particle size of the construction waste fragments is preferably below 400 m...

Embodiment 2

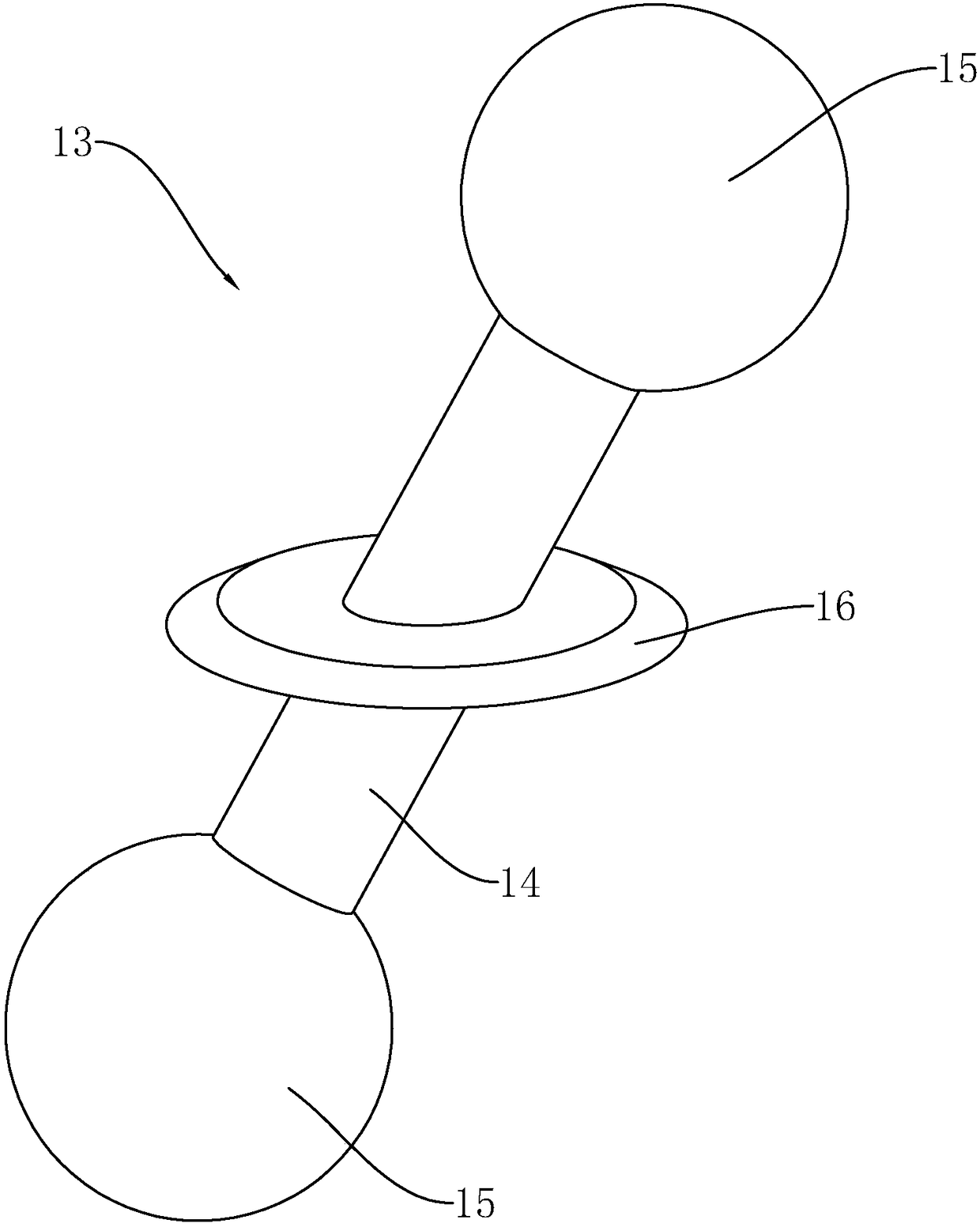

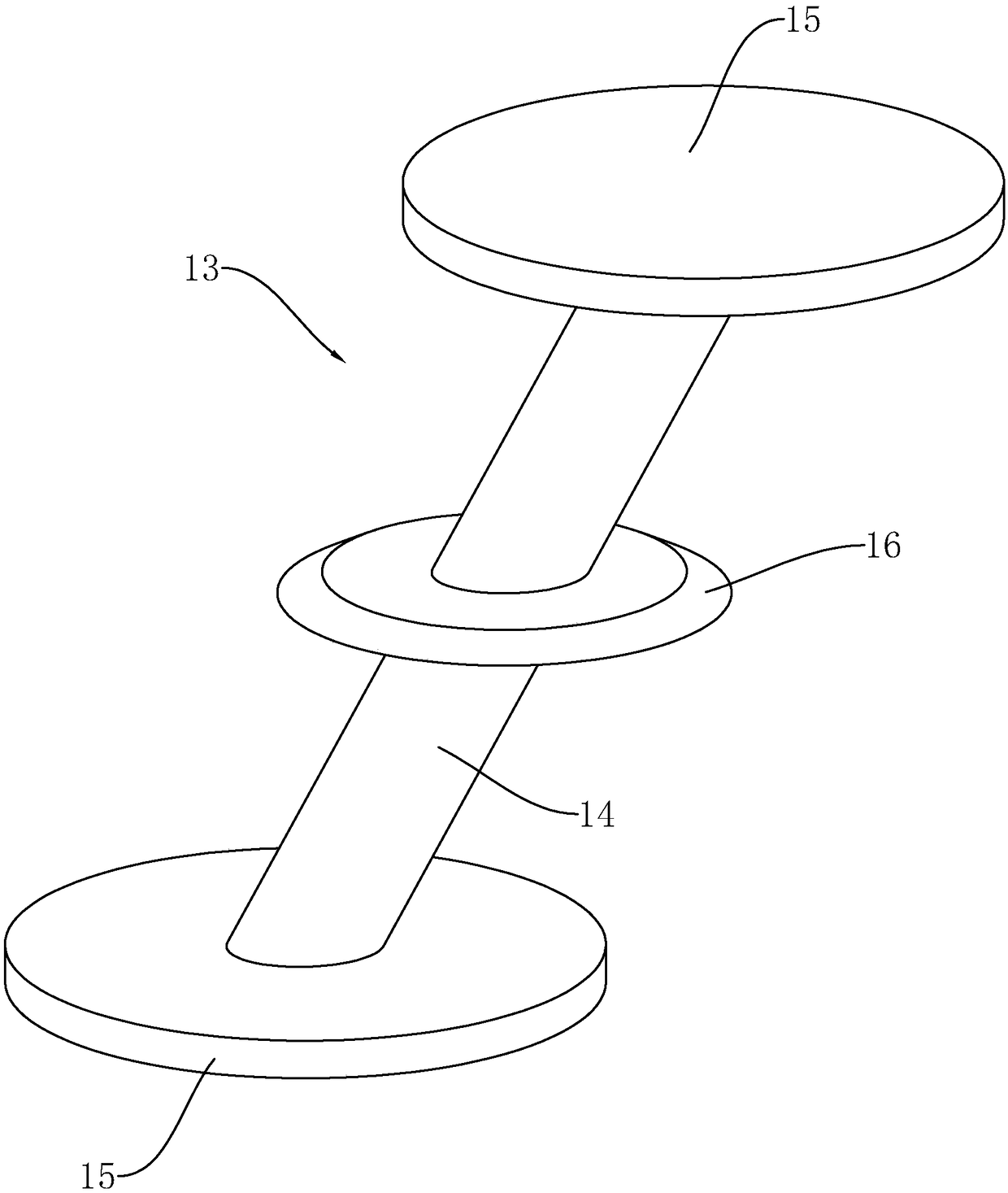

[0038] Such as image 3 As shown, the difference from Embodiment 1 is that the protruding member 15 is preferably disc-shaped, and its end face is parallel to the end face of the positioning disc 16, and the diameter of the protruding member 15 is greater than the outer diameter of the connecting rod 14, and at the same time The end of the connecting rod 14 is preferably fixed at the center of the protruding part 15 . The disc-shaped protrusions 15 can further enhance the nail-holding force at both ends of the connecting rod 14, so that the two ends of the connecting rod 14 are not easy to be separated from the concrete mortar surface layer 1 and the steel fiber concrete layer 2, further improving the concrete mortar surface layer. 1 and the firmness of the connection between the steel fiber reinforced concrete layer 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com