Prefabricated assembly-type balcony

A prefabricated assembly and balcony technology, applied to balconies, building components, buildings, etc., can solve the problems that affect the living experience of residents and the inability of balconies to effectively adjust the sunshine conditions, so as to reduce the transmission of solar heat and visible light, improve the accommodation experience, and improve the lighting Effects with adjustable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

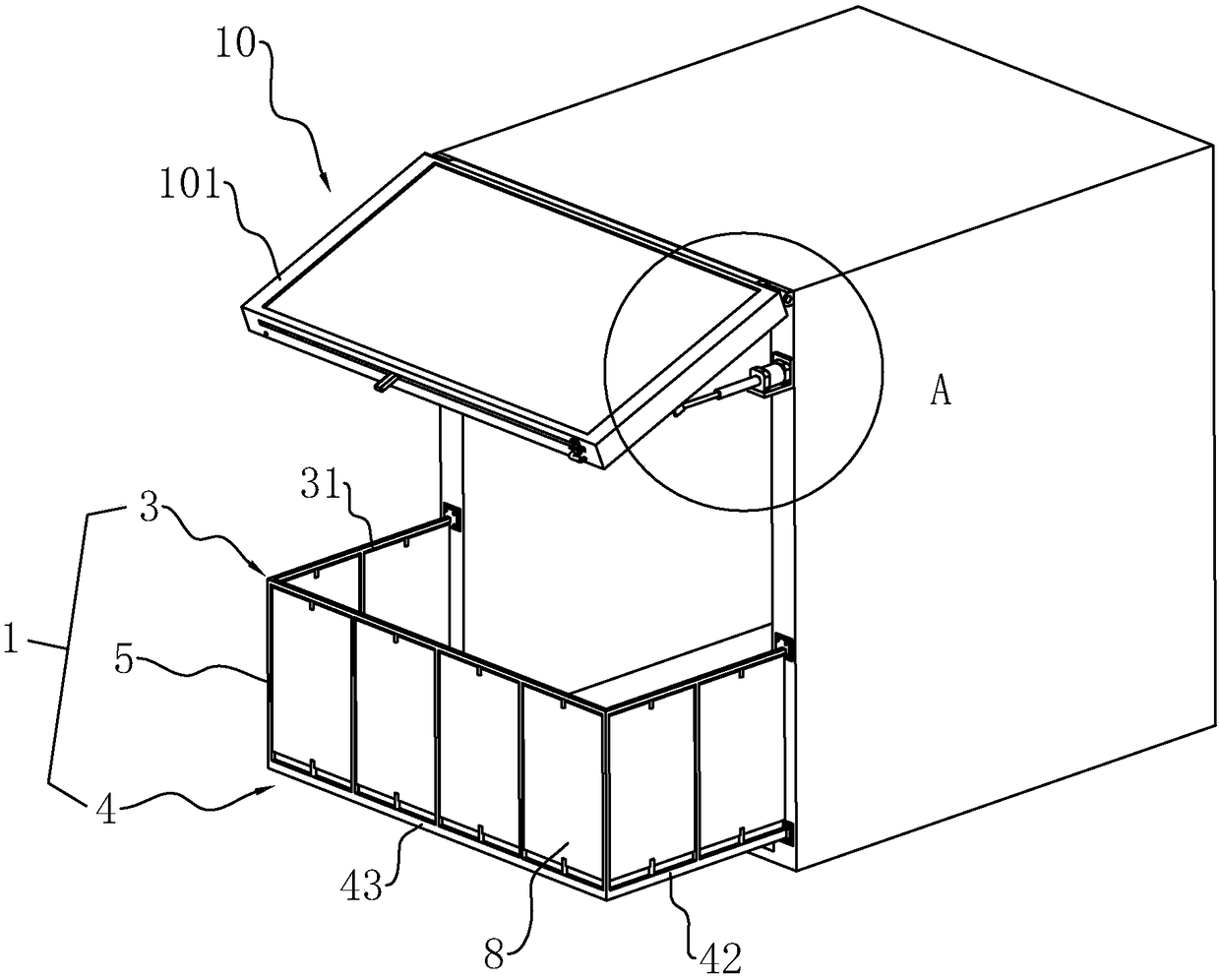

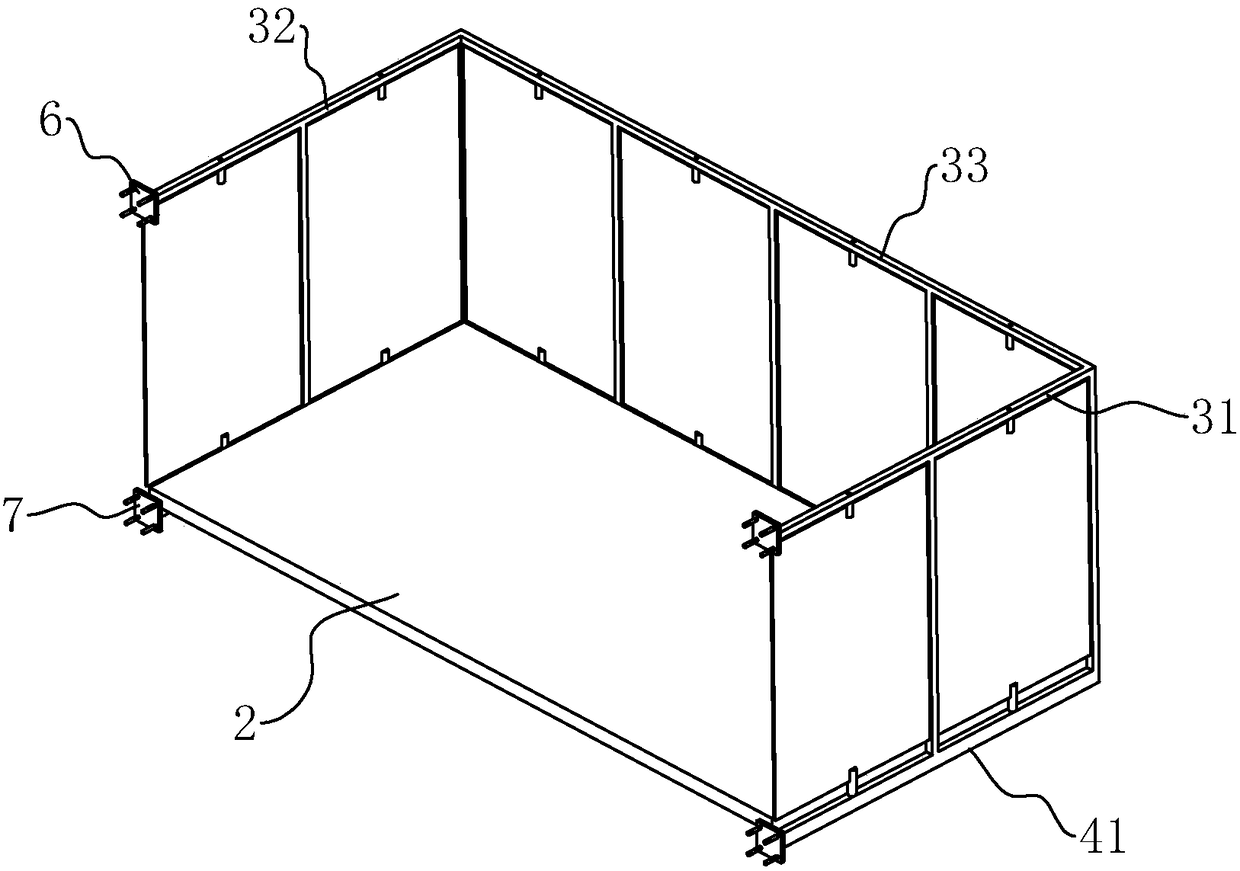

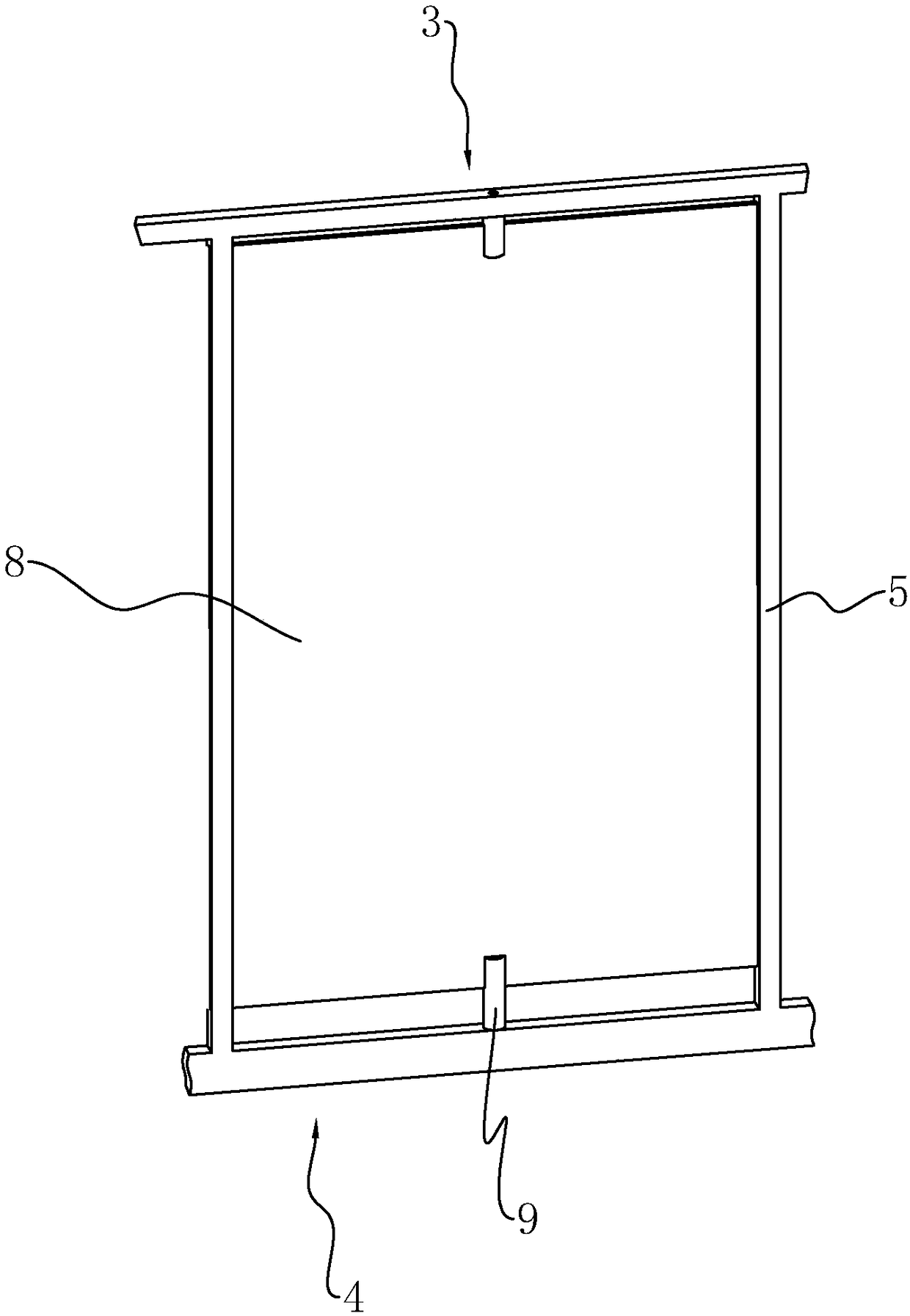

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] See attached Figure 1-2 , a prefabricated assembled balcony, including a support frame 1 and a balcony plate 2, the support frame 1 includes an upper chord 3, a lower chord 4 and a web 5, and the upper chord 3 and the lower chord 4 are fixedly connected through the web 5. Wherein, upper chord 3 comprises left upper chord 31, right upper chord 32 and front upper chord 33, and front upper chord 33 is fixedly connected with the front end of left upper chord 31 and right upper chord 32 respectively, left upper chord 31 and right upper chord 32 An upper connecting plate 6 is welded and fixed at one end away from the front upper chord 33, which is used for welding or bolting the embedded plate in the wall. Similarly, the lower chord 4 includes a left lower chord 41, a right lower chord 42 and a front lower chord 43, and the front lower chord 43 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com