Cross layer drilling separated type whole-course gas extraction hole sealing device and method

A technology of gas drainage and layer-crossing drilling, which is applied in safety devices, gas discharge, earthwork drilling and mining, etc. It can solve the problems of long butt joint time of sealing pipes, fast flow attenuation, and easy falling off of drilling holes, etc., and achieves a simple structure , reduce leakage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

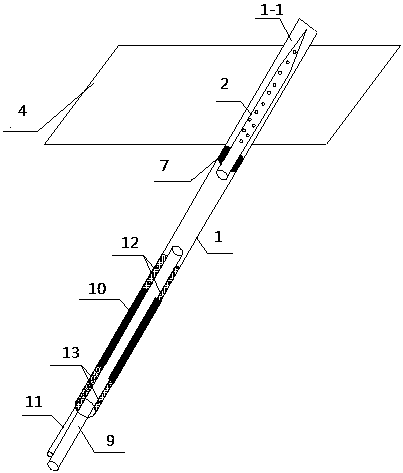

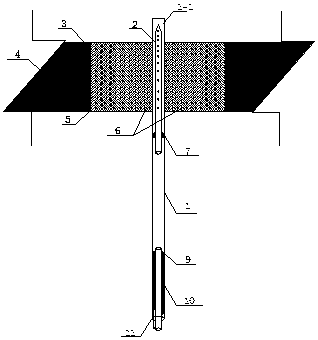

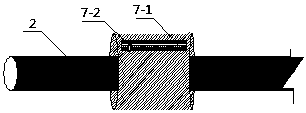

[0039] like Figure 1~6 As shown, a kind of perforated drilling separation type full-process gas drainage sealing device includes: a borehole 1 drilled in the coal seam, and the top of the borehole 1 is at two 1Formation of the coal seam Drilling gas chamber 1-1, the inner cavity of the drilling gas chamber 1-1 is provided with an upper sealing pipe 2, the lower end of the drilling 1 is provided with a lower sealing pipe 9, and the upper sealing pipe 9 2 is provided with a hole, the lower sealing tube 9 has no holes, the top of the upper sealing tube 2 is provided with a conical plug 2-1, the upper sealing tube 2 is provided with a sealing tube fixing device 7, The upper sealing pipe 2 pushes against the conical plug 2-1 through the push rod 14 to send the upper sealing pipe 2 into the upper part of the drilling air chamber 1-1, and the outer pipe wall of the lower sealing pipe 9 and the drilling air chamber 1-1 The cavity formed by the inner tube wall is provided with an upp...

Embodiment 2

[0049] like Figure 1~6 As shown, a kind of perforated drilling separation type full-process gas drainage sealing device includes: a borehole 1 drilled in the coal seam, and the top of the borehole 1 is at two 1 Formation of the coal seam Drilling gas chamber 1-1, the inner cavity of the drilling gas chamber 1-1 is provided with an upper sealing pipe 2, the lower end of the drilling 1 is provided with a lower sealing pipe 9, and the upper sealing pipe 9 2 is provided with a hole, the lower sealing tube 9 has no holes, the top of the upper sealing tube 2 is provided with a conical plug 2-1, the upper sealing tube 2 is provided with a sealing tube fixing device 7, The upper sealing pipe 2 pushes against the conical plug 2-1 through the push rod 14 to send the upper sealing pipe 2 into the upper part of the drilling air chamber 1-1, and the outer pipe wall of the lower sealing pipe 9 and the drilling air chamber 1-1 The cavity formed by the inner tube wall is provided with an up...

Embodiment 3

[0059] like Figure 1~6 As shown, a kind of perforated drilling separation type full-process gas drainage sealing device includes: a borehole 1 drilled in the coal seam, and the top of the borehole 1 is at two 1 Formation of the coal seam Drilling gas chamber 1-1, the inner cavity of the drilling gas chamber 1-1 is provided with an upper sealing pipe 2, the lower end of the drilling 1 is provided with a lower sealing pipe 9, and the upper sealing pipe 9 2 is provided with a hole, the lower sealing tube 9 has no holes, the top of the upper sealing tube 2 is provided with a conical plug 2-1, the upper sealing tube 2 is provided with a sealing tube fixing device 7, The upper sealing pipe 2 pushes against the conical plug 2-1 through the push rod 14 to send the upper sealing pipe 2 into the upper part of the drilling air chamber 1-1, and the outer pipe wall of the lower sealing pipe 9 and the drilling air chamber 1-1 The cavity formed by the inner tube wall is provided with an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com