Drying apparatus for gypsum plates as building wall decorative plates

A technology for decorative panels and building walls, applied in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc. Good drying effect, increased contact time, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

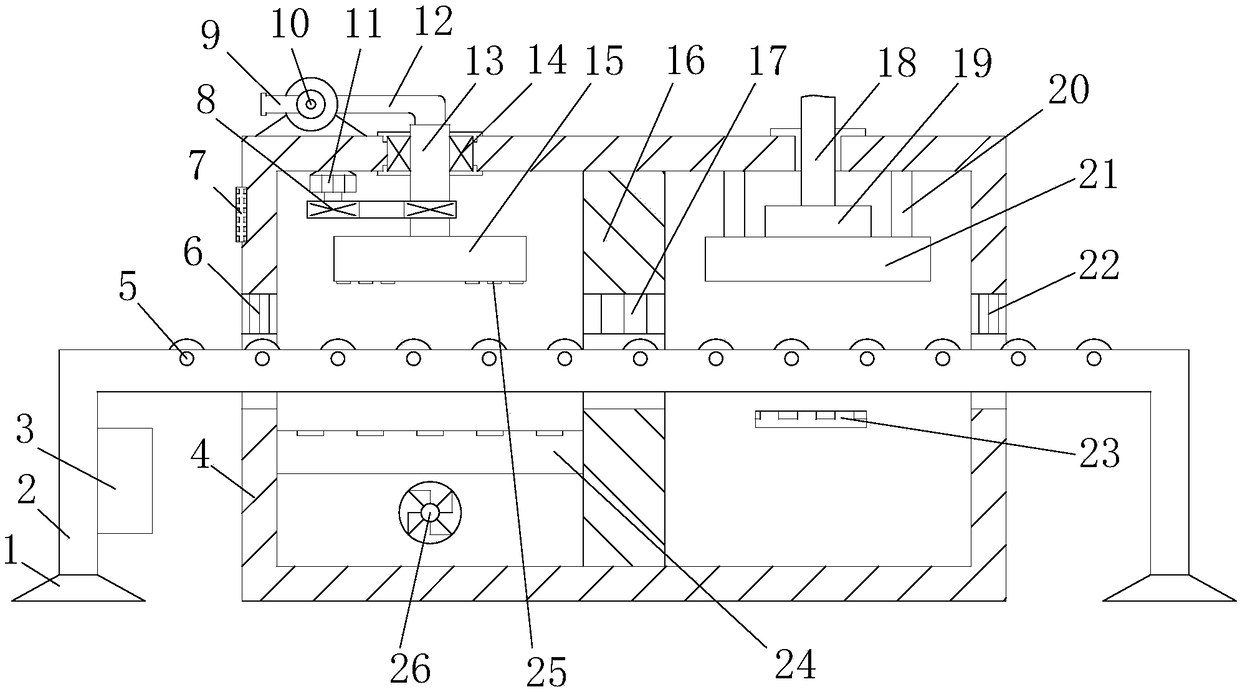

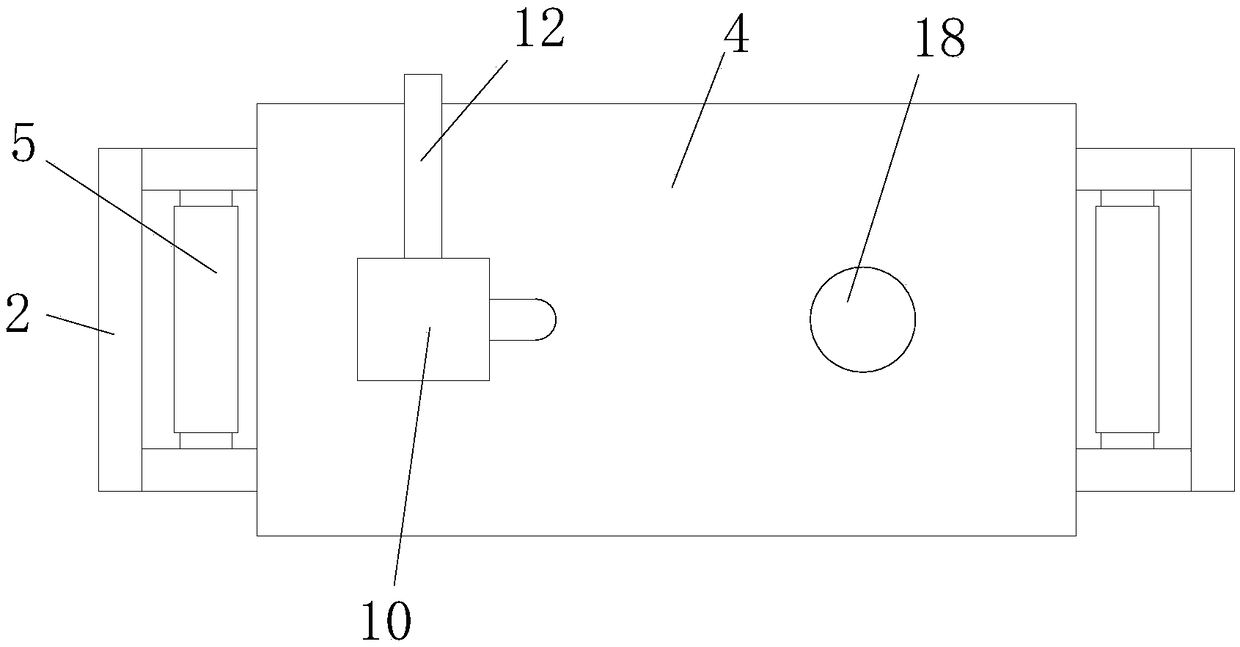

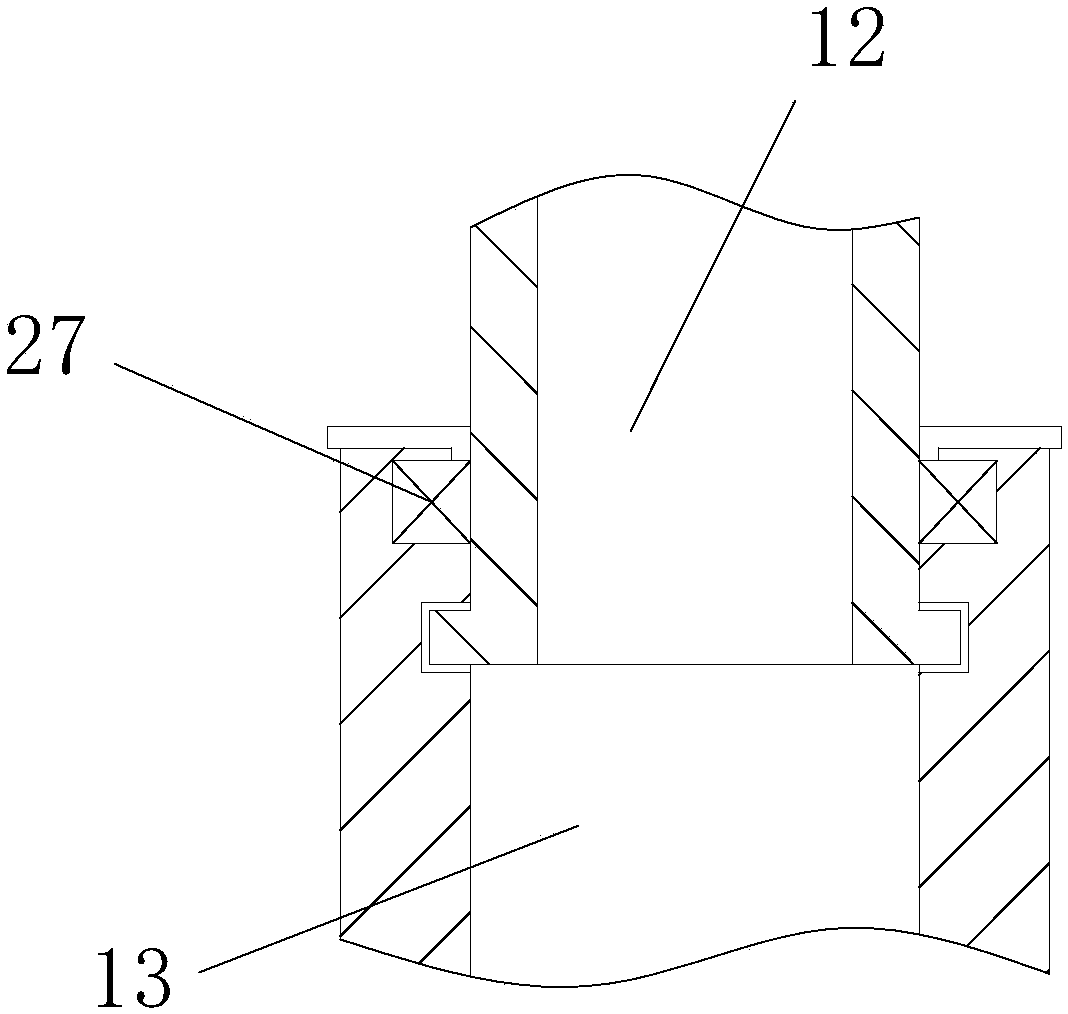

[0020] see Figure 1-4 , a kind of drying equipment for the processing of plasterboard, a building wall decoration board, comprising a drying box 4; The other parts on the board provide installation space; the bottom of the control switch 7 is provided with a feed port 6; The gypsum board is input into the box; the main body frame 2 is horizontally connected to the inside of the drying box 4, and a transmission wheel roller 5 is installed on it. The upper gypsum board is transported; the main body frame 2 is equipped with a transmission box 3, and its lower end is welded with a foot 1, which provides rotational power for the transmission wheel roller 5; The air distribution plate 24 is welded horizontally on the left lower inner wall of the drying box 4, and its rear end is connected to the air duct 12, and the hot air is transported to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com