Combustion measurement device and measurement method for injection-assisted sintering method

A technology of auxiliary combustion and auxiliary sintering, applied in the field of sintering, can solve the problems of affecting the sintering process, not knowing the thickness of the combustion zone, safety accidents, etc., and achieve the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

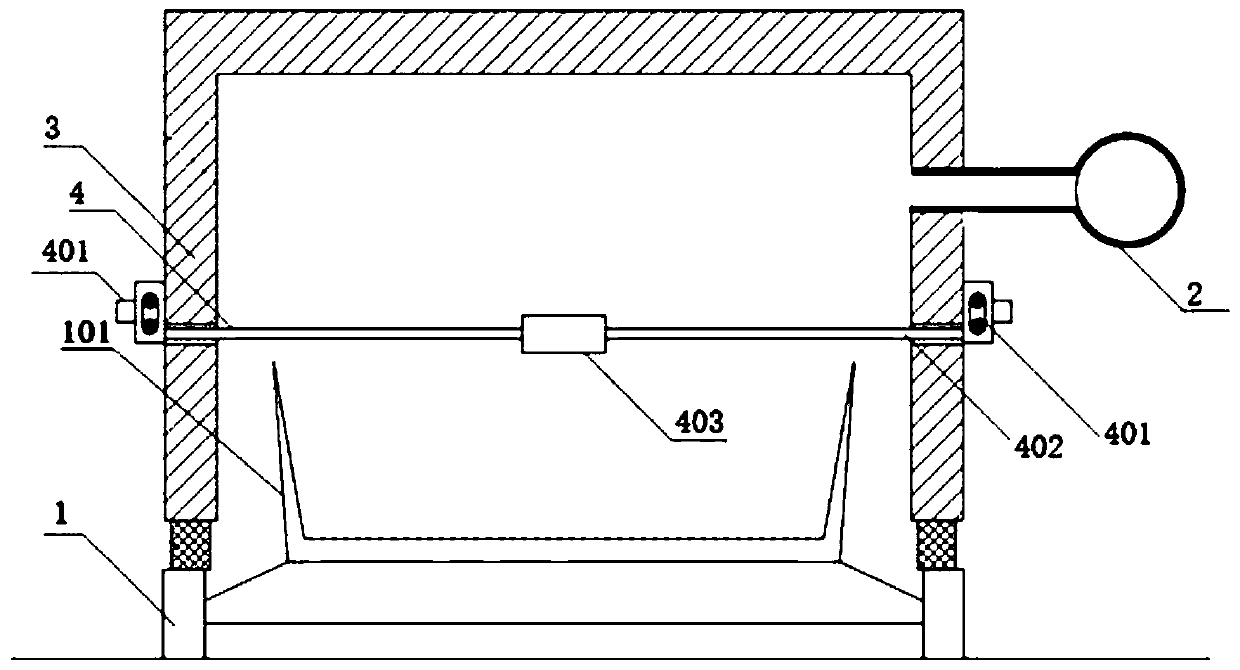

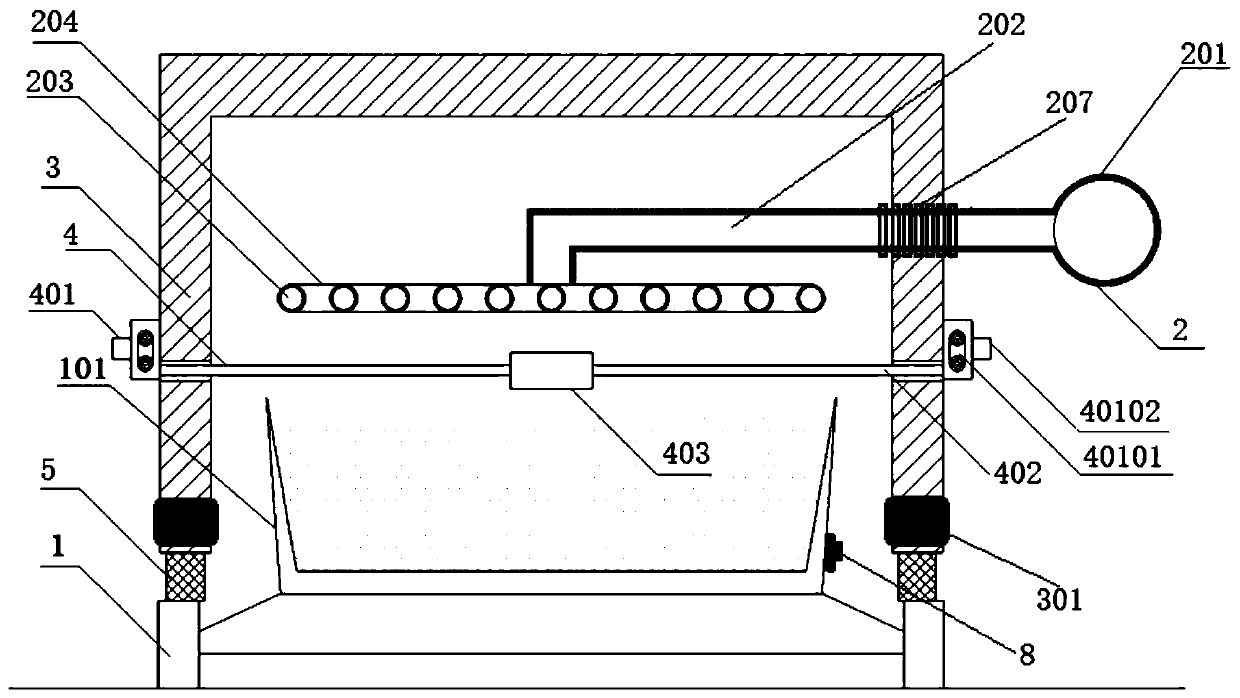

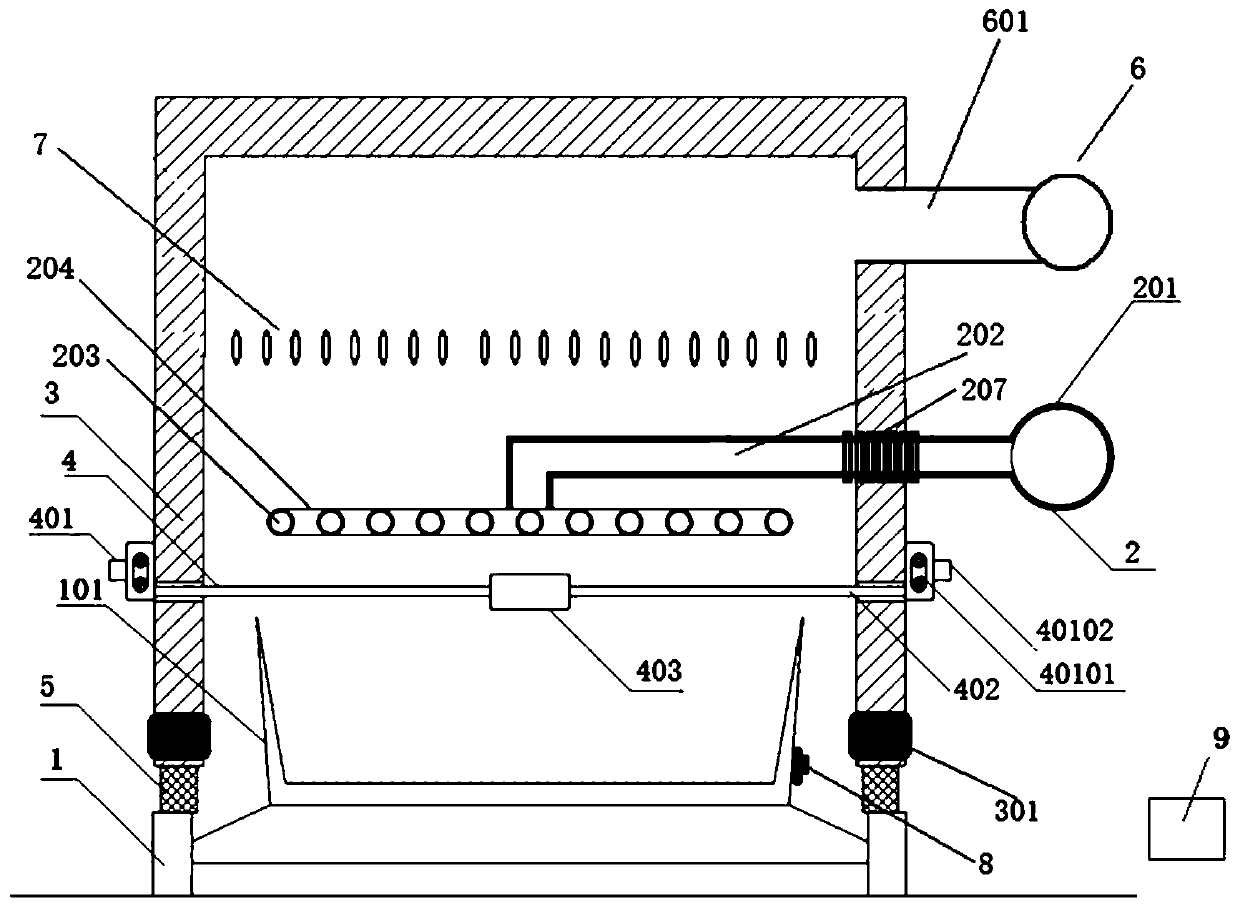

Embodiment 1

[0110] A gas combustion position measuring device for injection auxiliary sintering method, the device includes a sintering machine 1, an injection device 2 and an auxiliary combustion hood 3, the sintering machine 1 includes a trolley 101, the trolley 101 is located in the auxiliary combustion hood 3, and the injection The blowing device 2 is arranged above the trolley 101 , and the device is also provided with a gas concentration detection device 4 . The gas concentration detection device 4 is arranged above the trolley 101 . The gas concentration detection device 4 includes a driving device 401 , a traction component 402 , and a concentration detector 403 . The driving device 401 is arranged on the side wall of the auxiliary combustion cover 3 . The traction component 402 is connected to the driving device 401 . The concentration detector 403 is arranged on the traction member 402 . The blowing device 2 includes a gas main pipe 201 , a gas branch pipe 202 , a blowing pip...

Embodiment 2

[0112] Example 1 is repeated, except that the device further includes guide rails 40103 . The guide rail 40103 is arranged on the auxiliary combustion cover 3 parallel to the running direction of the trolley 101 . The driving device 401 can move forward and backward on the guide rail 40103 along the running direction of the trolley 101 .

Embodiment 3

[0114] Embodiment 2 is repeated, except that a section of metal hose 207 is provided on the gas branch pipe 202 , and the metal hose 207 is located at the junction of the gas branch pipe 202 and the auxiliary combustion hood 3 . The lower part of the auxiliary combustion cover 3 is provided with a lifting device 301 . The lifting device 301 is preferably an electric screw type lifting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com