Ozone oxidation catalyst as well as preparation method and application thereof

An ozone oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of increasing economic pressure, high price, low catalytic performance of catalysts, etc. problem, to achieve the effect of improving utilization efficiency and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Mix 325-mesh rho-type alumina and zinc oxide to obtain a mixture, wherein the mixture contains 4-10% by mass of zinc oxide. Spherical molding is performed using a spheronizer. Select a round disc of 1-3m, continuously add the mixture into the opened round disc at a feeding rate of 100kg / h, and at the same time spray water into the round disc at a rate of 50kg / L, until a small disc with a diameter of about 1-9mm is obtained. When the ball is made, take it out for use to obtain the required material ball.

[0034] (2) The collected pellets were placed in a closed system and treated at a constant temperature of 90° C. for 24 hours.

[0035] (3) Add the pellets treated in step (2) continuously into the vertical kiln, and adjust the pellets to stay in the kiln at a constant temperature of 450° C. for 3 hours by controlling the discharge speed at the bottom of the furnace to obtain an ozone oxidation catalyst.

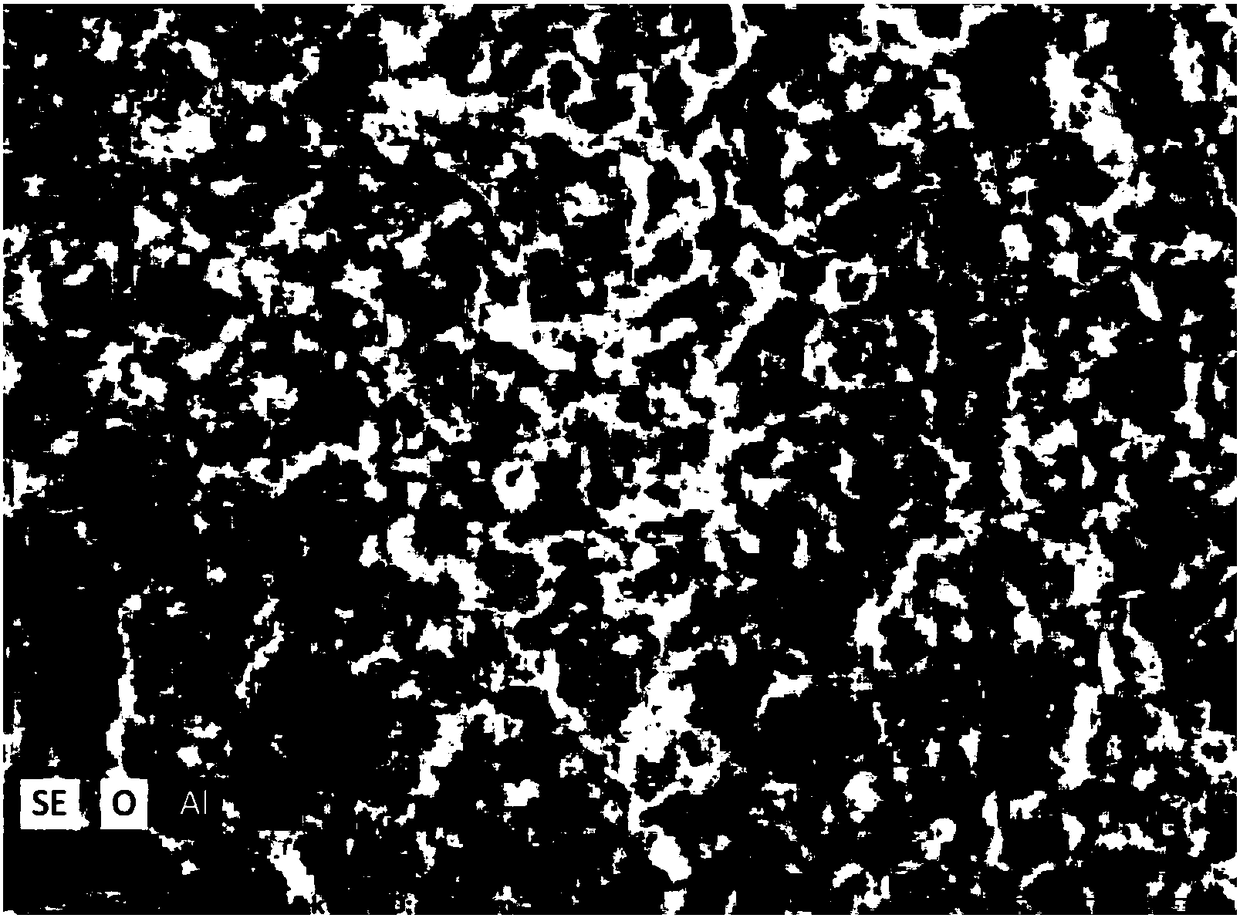

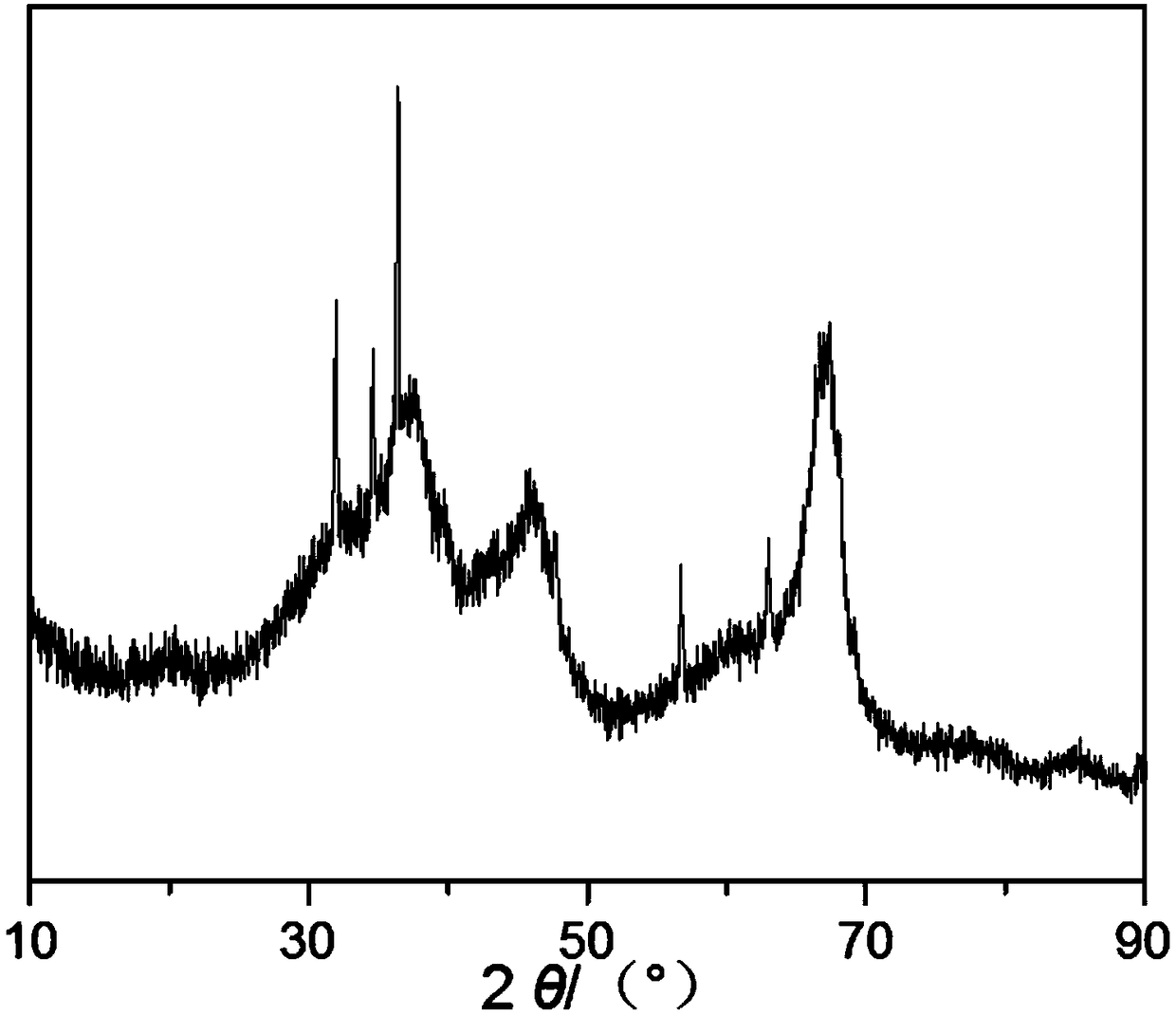

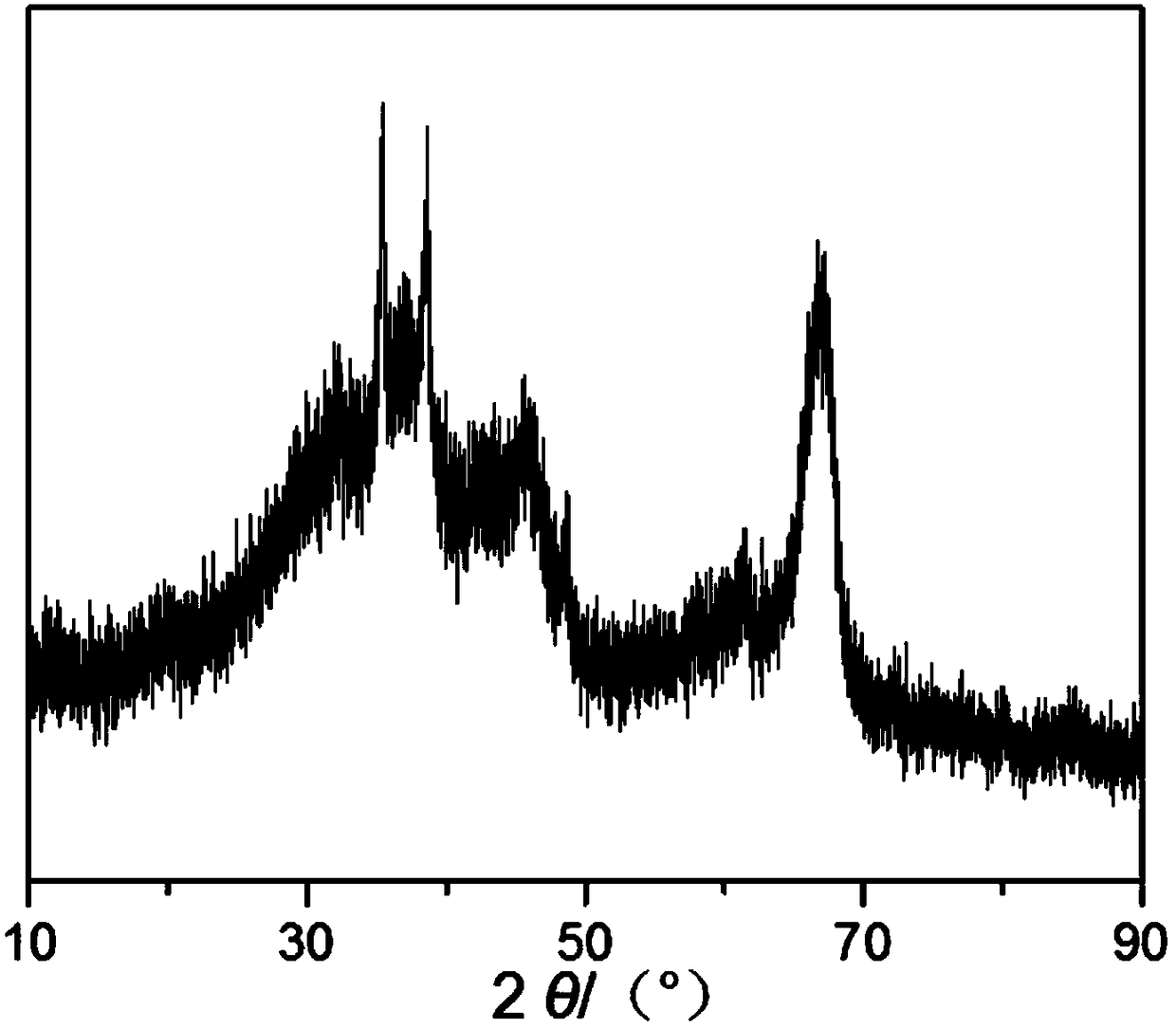

[0036] figure 1 , 2 , 5, and 6 are energy dispersive X-r...

Embodiment 2

[0040] (1) Mix 200-mesh rho-type alumina and zinc oxide to obtain a mixture, wherein the mixture contains 4-10% by mass of zinc oxide. Spherical molding is performed using a spheronizer. Select a round disc of 1-3m, continuously add the mixture to the opened round disc at a feeding rate of 100kg / h, and at the same time spray water into the round disc at a rate of 50kg / L and then spray an appropriate amount of water until the diameter is When the ball is about 6-9mm, take it out for use to obtain the required material ball.

[0041] (2) The collected pellets were placed in a closed system and treated at a constant temperature of 60° C. for 24 hours.

[0042] (3) Add the pellets processed in step (2) continuously into the vertical kiln, and adjust the pellets to stay in the kiln constant temperature zone of 500° C. for 3 hours by controlling the discharging speed at the bottom of the furnace to obtain an ozone oxidation catalyst.

Embodiment 3

[0044](1) Mix 325-mesh rho-type alumina and zinc oxide to obtain a mixture, wherein the mixture contains 4-10% by mass of zinc oxide. Spherical molding is performed using a spheronizer. Select a round disc of 1-3m, continuously add the mixture to the opened round disc at a feeding rate of 100kg / h, and at the same time spray water into the round disc at a rate of 50kg / L and then spray an appropriate amount of water until the diameter is When the ball is about 1-3mm, take it out for use to obtain the required material ball.

[0045] (2) The collected pellets were placed in a closed system and treated at a constant temperature of 90° C. for 24 hours.

[0046] (3) Add the pellets processed in step (2) continuously into the vertical kiln, and adjust the pellets to stay in the kiln constant temperature zone of 550° C. for 3 hours by controlling the discharging speed at the bottom of the furnace to obtain an ozone oxidation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com