Foam melamine thermal insulation board

A thermal insulation board and melamine technology, which is applied in the field of indoor thermal insulation boards, can solve the problems of large volume, insufficient durability, and inability to flame-retardant, and achieve the effects of simple production process, flammability, and good flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

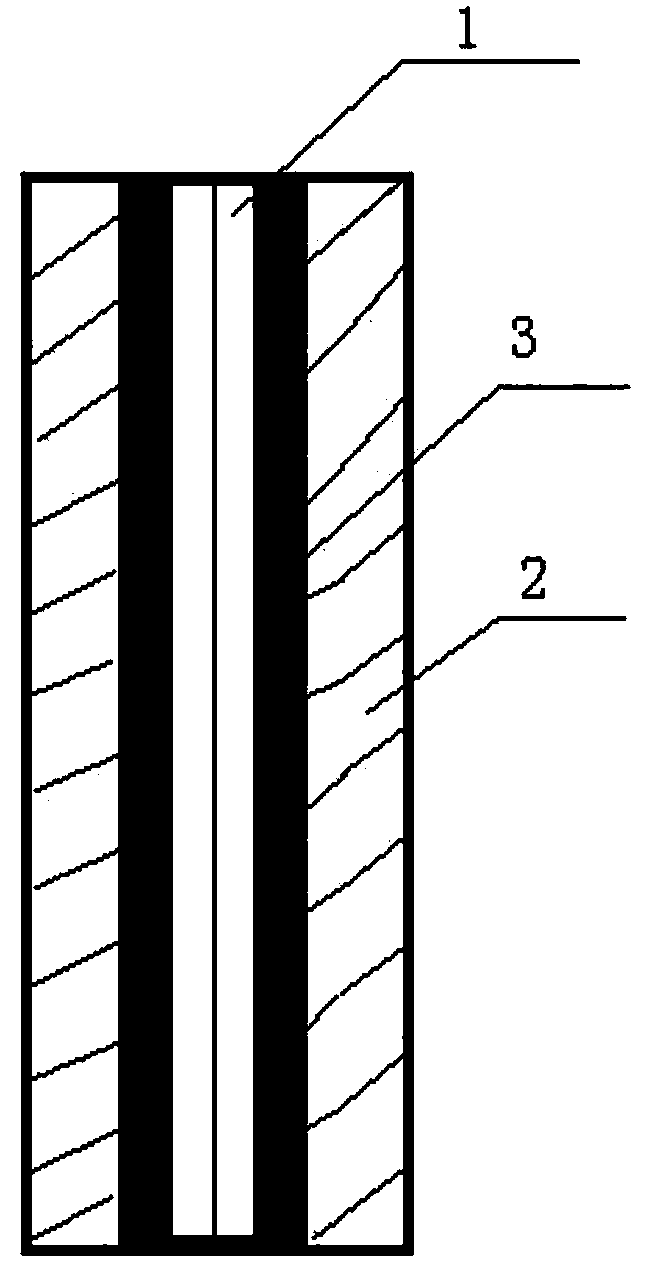

[0016] A foamed melamine insulation board is characterized in that: it comprises a melamine resin insulation layer 1, a barrier plate 2, and a foam layer 3; the melamine resin insulation layer 1 is a double-layer structure with the same thickness; The amine resin insulation layer 1 corresponds to bonding one layer of the foam layer 3, and the thickness of the two layers of the foam layer 3 is the same; the surface layer of each layer of the foam layer 3 corresponds to bonding one layer of the barrier plate 2, and the two layers of the barrier plate 2 have the same thickness.

[0017] The weight percentage of the melamine resin insulation layer is composed of: 2-5% of functional powder, 2-5% of inorganic antibacterial agent and 90-96% of mela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com