Manufacturing method for consumable electrode for TC26 titanium alloy smelting

A technology for consumable electrodes and titanium alloys, applied in the field of titanium material processing, can solve problems such as cost increase, and achieve the effects of good welding, increased connection strength, and not easy to fall out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

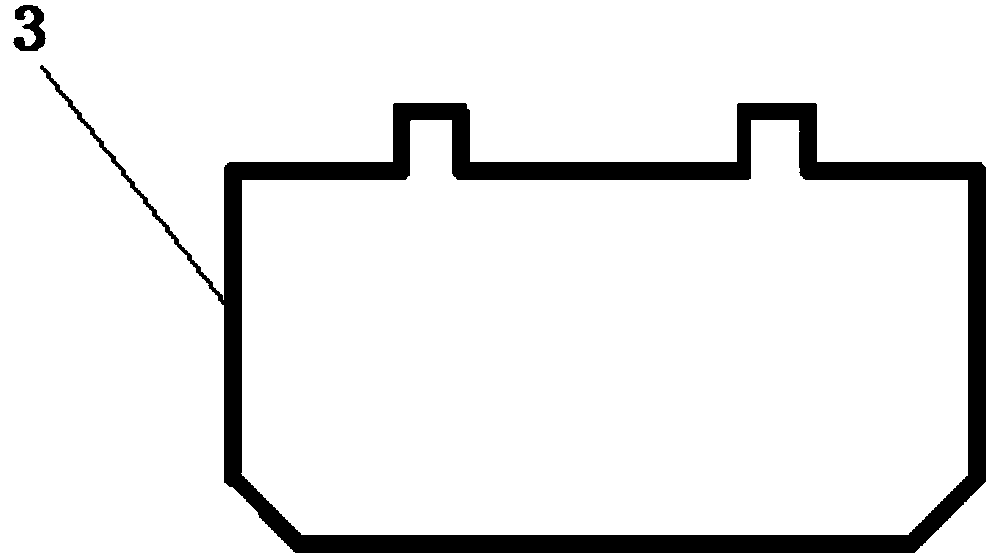

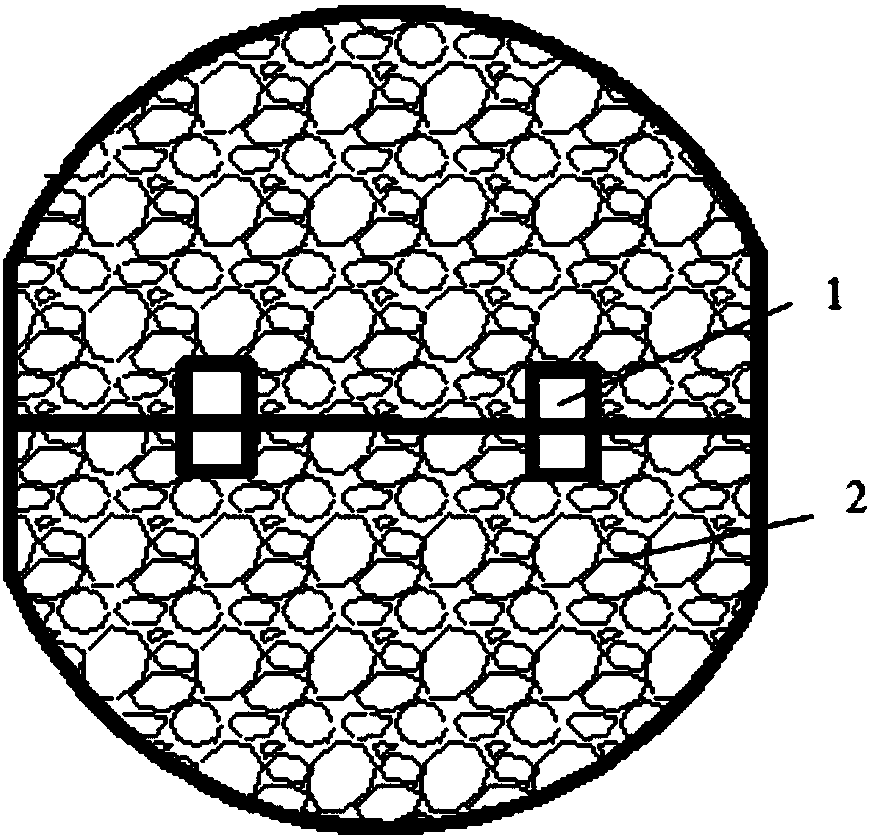

[0030] Example: The preparation method of the Φ380-600Kg self-consumable smelting electrode block of TC26 (Ti-13Nb-13Zr) alloy. The raw materials are 0-grade sponge titanium, industrial-grade HZr-1 sponge zirconium, and Nb bars with the brand name TNb1. The ratio is according to Ti-13.2%Nb-13.0%Zr (wt%). A shoulder-shaped pressing die is used, and 1 / 2 of the sponge titanium and sponge zirconium mixed according to the alloy composition ratio are firstly pressed to obtain a 1 / 2 electrode block with grooves. Repeat the operation to obtain another 1 / 2 electrode block. Put 4 Nb strips into the 4 grooves and weld them together. Finally, a single consumable electrode block of TC26 titanium alloy of Φ160-20Kg is tailor-welded. A total of 30 electrode blocks were prepared and welded into 4 consumable electrodes. Subsequent vacuum self-consumption smelting three times to obtain Φ380-600Kg ingots. After measurement, the composition of the ingot is uniform, and no microstructure and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com