Nano-complexing film-forming agent

A technology for synthesizing film and film-forming agent, applied in the direction of metal material coating process, etc., can solve problems such as secondary rust, and achieve the effect of saving production cost, short processing time, and low water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

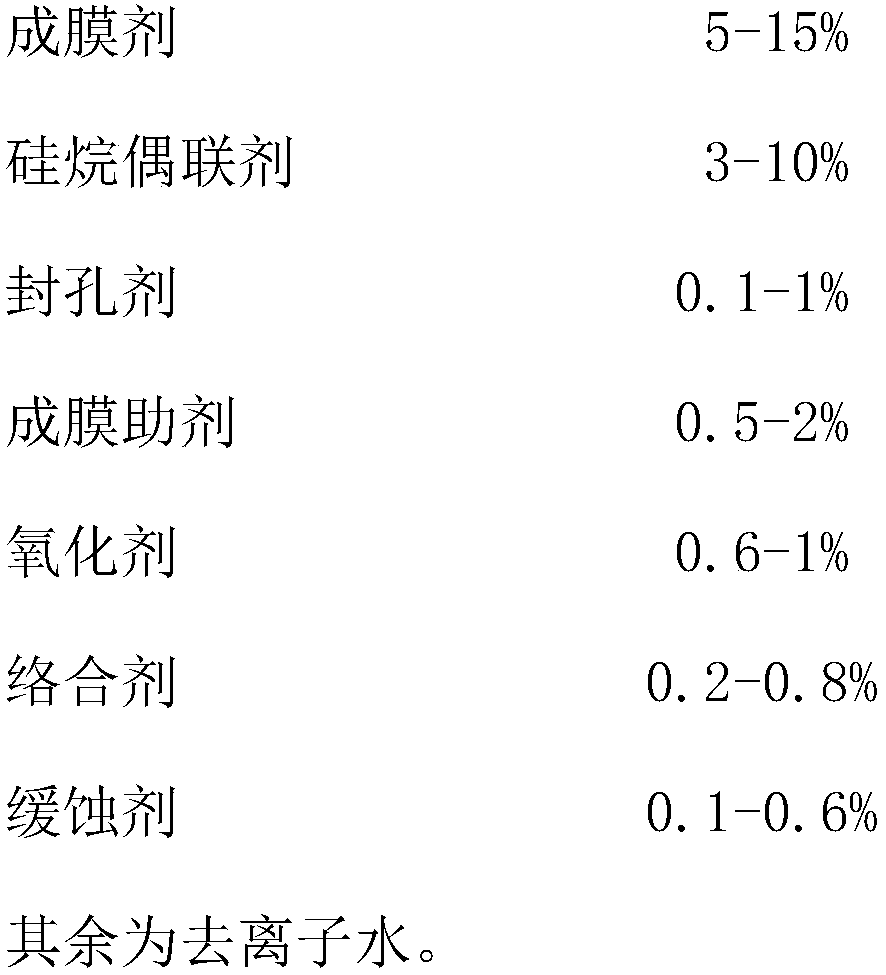

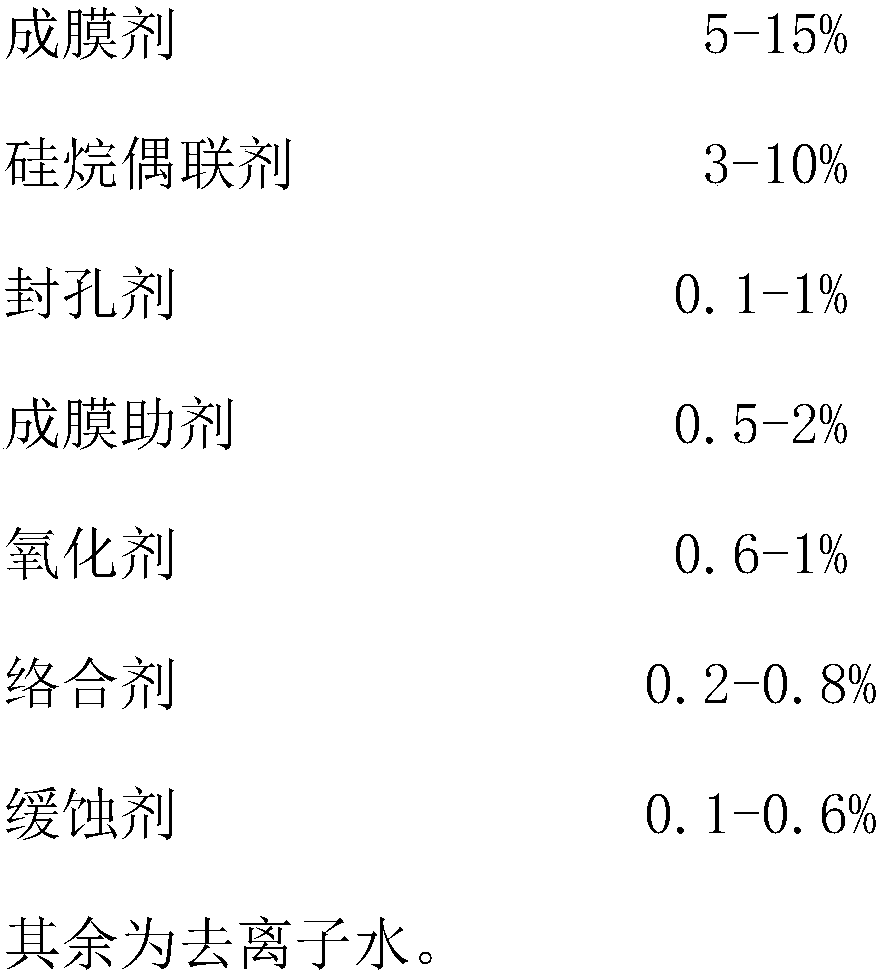

Method used

Image

Examples

Embodiment 1

[0030] A nano-complex membrane agent, which is composed of the following weight composition and components: fluorozirconic acid 15%, vinyl silane 6%, nano silica 0.5%, fluoroboric acid 1%, cerium nitrate 0.8%, citric acid 0.5% , Molybdate 0.2%, the balance is water.

[0031] Add 800 ml of water, stir well to dissolve and mix uniformly, add appropriate amount of water and mix uniformly to prepare 1 liter of film-forming agent.

[0032] Dilute the above-mentioned film-forming agent with water, prepare it with a volume ratio of film-forming agent to water 1:50, and adjust the pH to 4-4.8 with nitric acid.

[0033] When using the film-forming agent described in this embodiment, the workpiece is first subjected to degreasing and rust-removing treatment according to the above process, and then the film-forming agent of this embodiment is treated at room temperature for 3 to 5 minutes to form a layer on the surface of the workpiece. Complex film, and finally rinse with water. After drying...

Embodiment 2

[0041] A new type of nano-complex membrane agent, which is composed of the following weight composition and components: 5% fluorotitanic acid, 5% zirconium fluoride, 10% methacryloxysilane, 0.2% nano-titanium dioxide, 0.3% water-based graphene , Metatitanic acid 0.5%, fluorosilicic acid 1.2%, lanthanum nitrate 0.3%, cerium sulfate 0.3%, tartaric acid 0.1%, tannic acid 0.1%, corrosion inhibitor tungstate 0.2%, urotropine 0.1%, the rest The amount is water.

[0042] Add 800 ml of water, stir well to dissolve and mix well, add appropriate amount of water and mix well to prepare 1 liter of film-forming agent.

[0043] Dilute the above-mentioned film-forming agent with water, prepare the film-forming agent and water in a volume ratio of 1:30, and adjust the pH to 3.5-4.5 with sodium carbonate.

[0044] When using the film-forming agent described in this embodiment, the workpiece is first subjected to degreasing and rust-removing treatment according to the above process, and then washed w...

Embodiment 3

[0046] A new type of nano-complex membrane agent, which is composed of the following weight composition and components: zirconium oxychloride 2%, fluorozirconate 3%, aminosilane 3%, titanyl sulfate 0.1%, boric acid 0.2%, sodium silicate 0.3%, lanthanum sulfate 1%, ethylenediaminetetraacetic acid 0.4%, phytic acid 0.4%, benzotriazole 0.6%, and the balance is water.

[0047] Add 800 ml of water, stir well to dissolve and mix well, add appropriate amount of water and mix well to prepare 1 liter of film-forming agent.

[0048] Dilute the above-mentioned film-forming agent with water, prepare it with the volume ratio of film-forming agent to water 1:40, and adjust the pH to 4.5-5.0 with ammonia water.

[0049] When using the film-forming agent described in this embodiment, the workpiece is first subjected to degreasing and rust-removing treatment according to the above process, and then washed with water, and then the film-forming agent described in this embodiment is treated at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com