Hard and brittle mud shale fracturing pressure predicting method

A prediction method and fracture pressure technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., to achieve the effect of simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with embodiment.

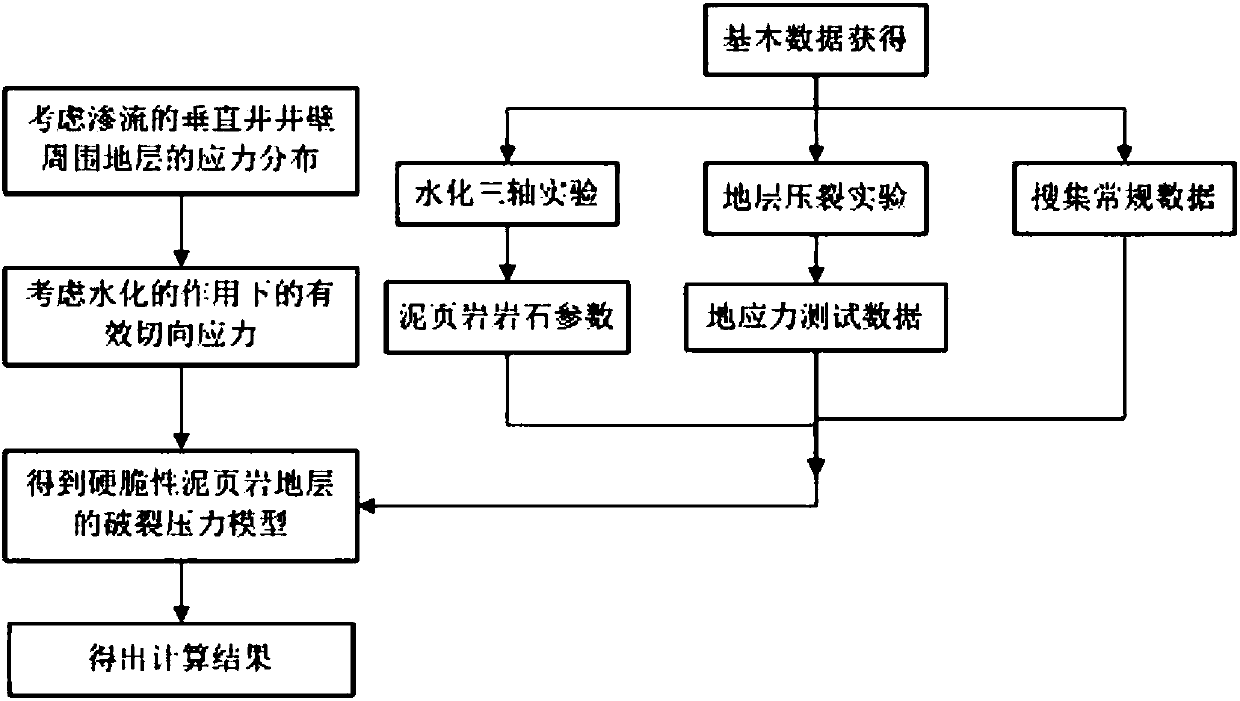

[0037] refer to figure 1 , a method for predicting fracture pressure of hard and brittle shale, comprising the following steps:

[0038] 1) Obtain rock parameters of hard and brittle shale through indoor hydration triaxial experiments, including rock compressive strength, elastic modulus and Poisson's ratio;

[0039] Testing the compressive strength, modulus of elasticity, and Poisson's ratio of rocks includes the following steps:

[0040] 1.1) Preparation of standard cylindrical rock samples: Prepared according to the recommended standards of the International Society of Rock Mechanics (ISRM), process the taken out shale cores into cylindrical standard samples with a diameter of 25.4mm and a height of 50mm, and the flatness of the end surface 0.1mm;

[0041] 1.2) Soak three sets of standard cylinder rock samples prepared in step 1.1) in distilled water for 1d, 3d and 5d respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com