Online gas making cracking device for methyl alcohol

A methanol and equipment technology, which is applied to the field of methanol on-line gas production and cracking equipment, can solve the problems of low temperature start, poor engine heating effect, poor low temperature start performance, etc., so as to solve the problem of low temperature cold start, simple structure, The effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

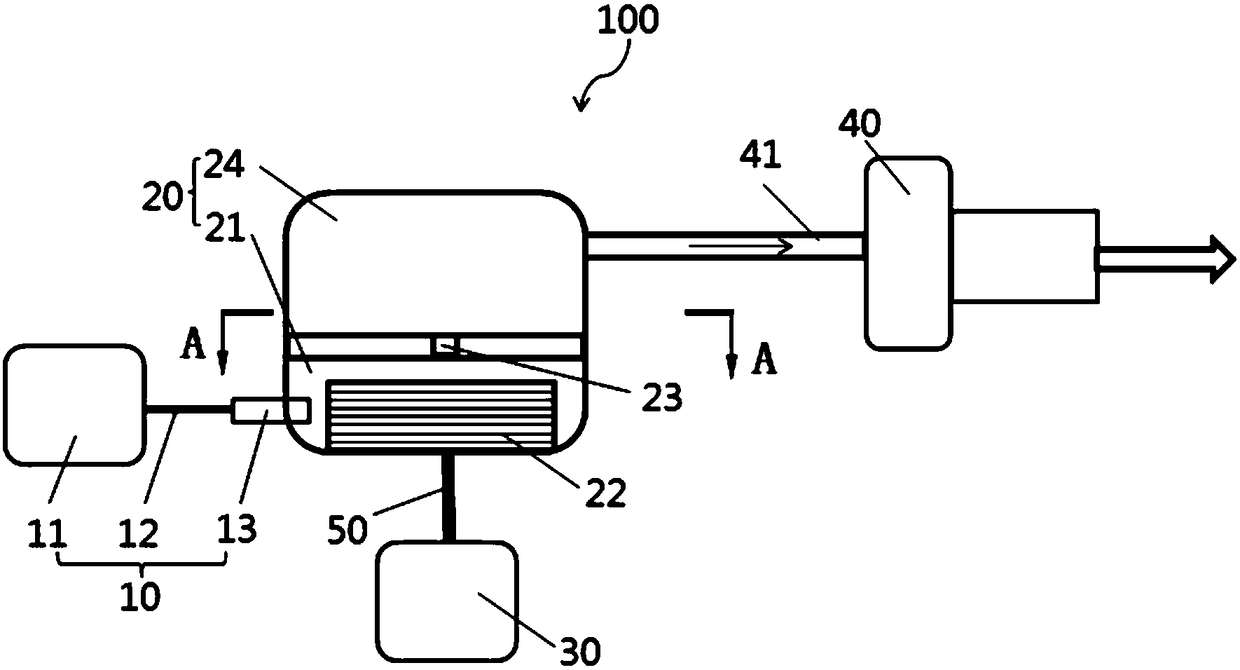

[0030] figure 1 It is a schematic structural diagram of an on-line methanol gas cracking device 100 according to an embodiment of the present invention. The online methanol gas production cracking equipment 100 of the present invention may generally include a methanol supply device 10 , a cracking gas production device 20 , a power supply device 30 and a mixer 40 . The methanol supply device 10 is used to supply methanol. The cracking gas generating device 20 is used to vaporize, burn and / or crack the methanol supplied from the methanol supply device 10 under low temperature conditions, wherein the methanol is vaporized to form methanol vapor, and the methanol vapor is further cracked Carbon monoxide and hydrogen are formed. The power supply device 30 is connected with the cracking gas generating device 20 and is used for providing electric energy to the cracking gas generating device 20 . The mixer 40 is connected with the cracking gas generator 20 and the engine, and is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com