Deformation testing device with wind power generator tower tube connected with foundation and application of deformation testing device

A technology of deformation testing and wind turbine foundation, applied in the installation/supporting configuration of wind turbines, wind turbine trial operation, wind turbine monitoring, etc., can solve the lack of testing devices and monitoring methods, lack of testing methods and methods for determining safety monitoring indicators , cumbersome and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0061] Choose one dual-axis inclination sensor with full temperature compensation and high precision, or two single-axis inclination sensors with full temperature compensation and high precision. Environmental changes have little impact.

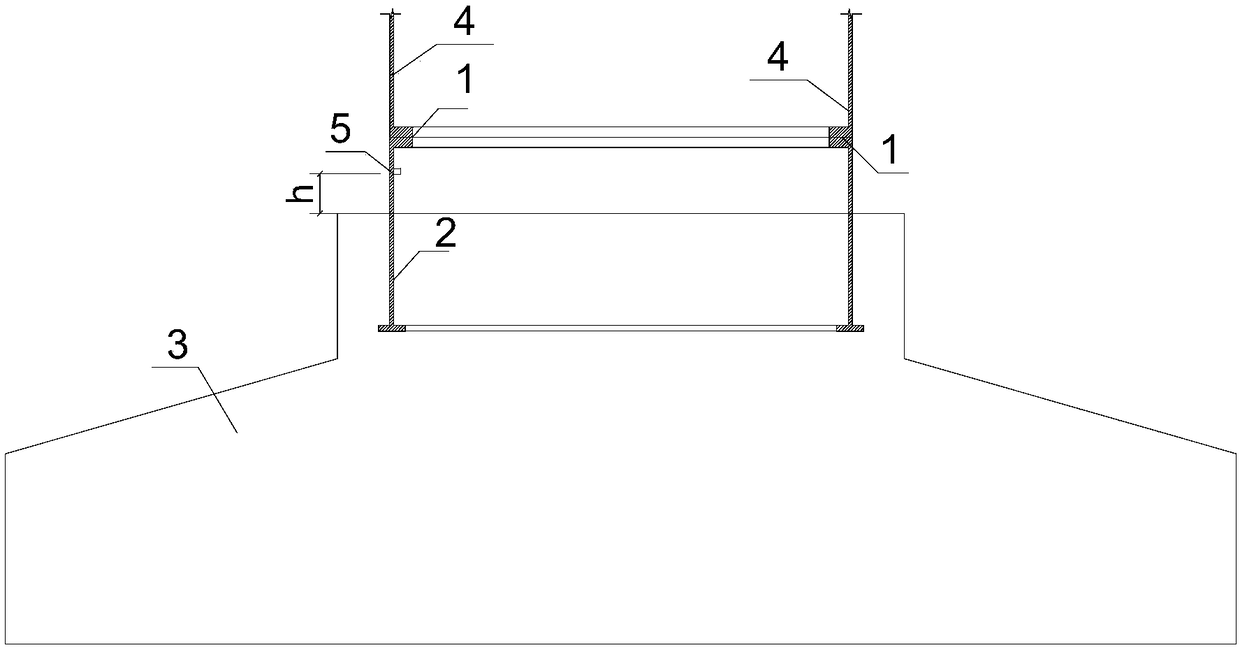

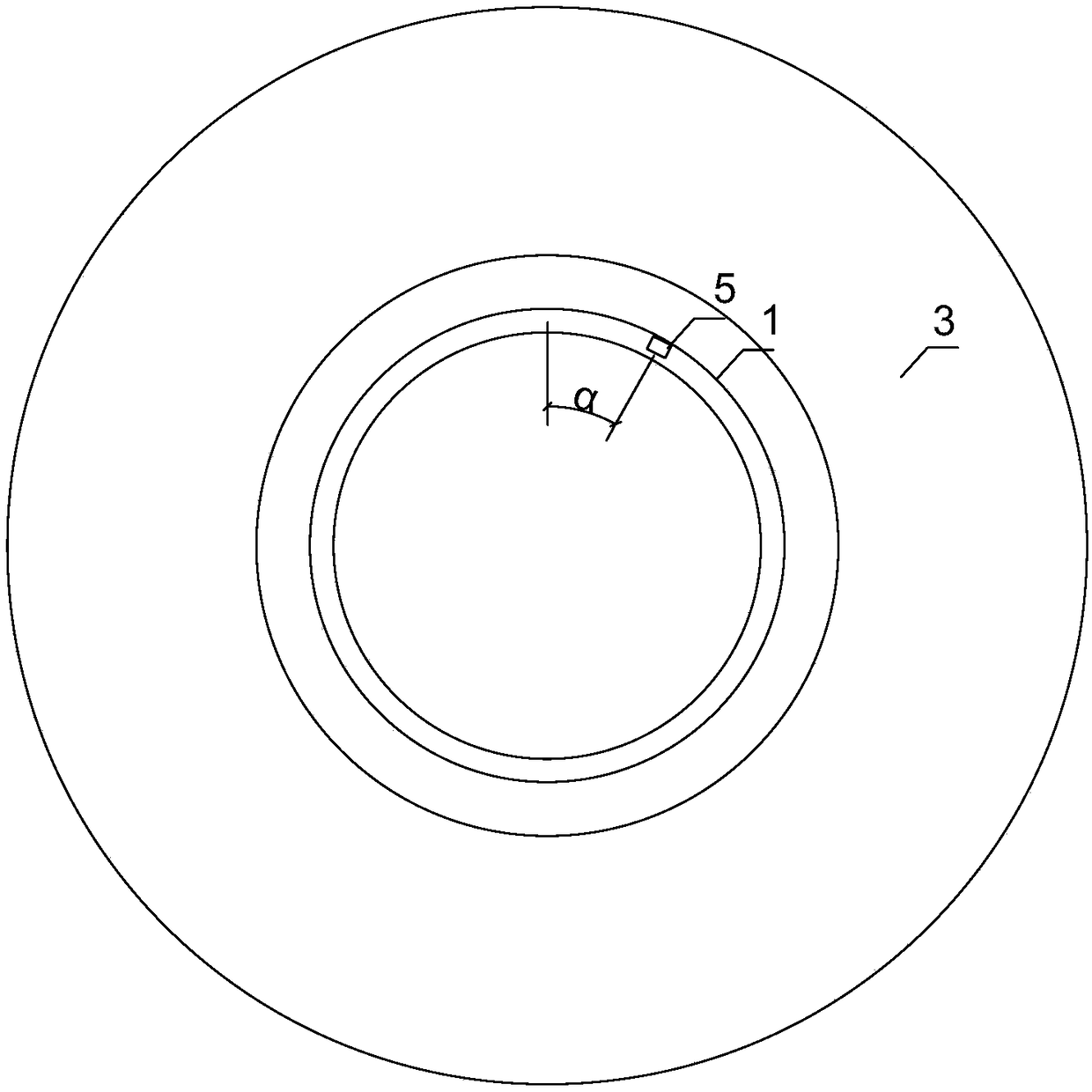

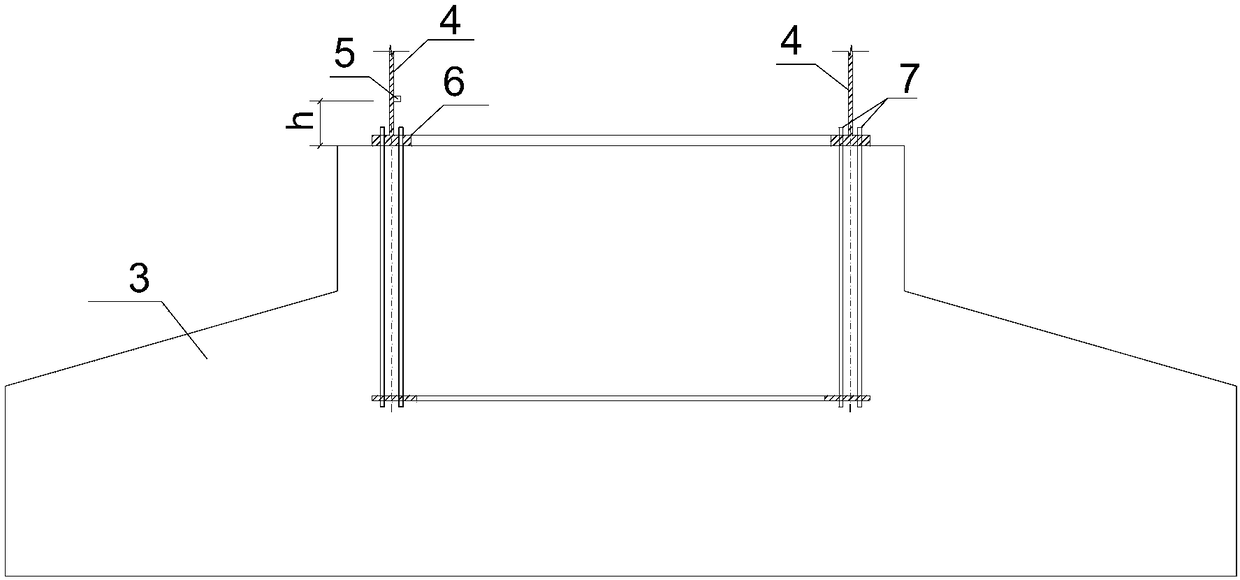

[0062] Such as figure 1 and figure 2 As shown, for the fan foundation connected by the foundation ring, the fan tower 4 is connected to the foundation ring 2 through the flange 1, and the inclination sensor 5 is close to the top surface of the concrete foundation. In this example, it is fixed on the inner wall of the foundation ring 2. 3. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com