Mechanical auxiliary overcooling CO2 cross-critical heat pump heating system

A mechanically assisted, transcritical technology, used in hot water central heating systems, heating systems, heat pumps, etc., can solve problems such as low energy efficiency, reduce CO2 operating pressure, ensure efficient operation, and reduce throttling losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

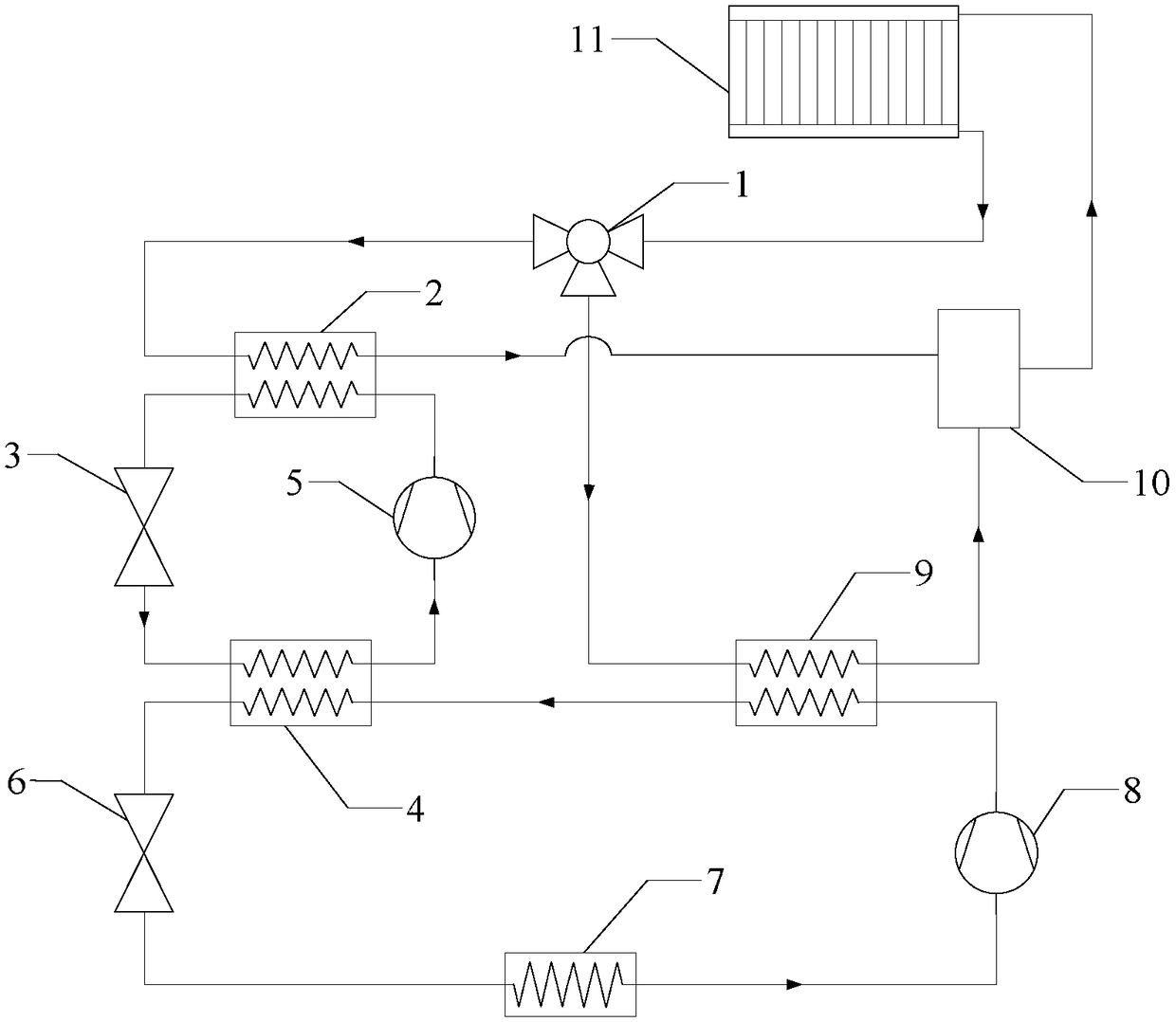

[0019] Step 1: After the return water passes through the three-way valve 1, it flows through the condenser 2 for heat exchange all the way, flows through the gas evaporator 9 for heat exchange all the way, and then reaches the mixing tank 10.

[0020] Step 2: The auxiliary circulation compressor 5 sucks the low-temperature and low-pressure refrigerant gas at the outlet of the cooling evaporator 4, compresses it into a high-temperature and high-pressure gas, and after exchanging heat with hot water, the temperature decreases, and then flows through the auxiliary circulation throttling Valve 3 throttles and reduces pressure, and becomes a gas-liquid two-phase state. After being evaporated and absorbed by the cooling evaporator 4, it becomes superheated gas and enters the compressor 5 to complete the auxiliary cycle.

[0021] The third step: the compressor 8 absorbs the low-temperature and low-pressure CO at the outlet of the evaporator 7 2 The gas is compressed into a high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com