A clamping device for blade profile measurement

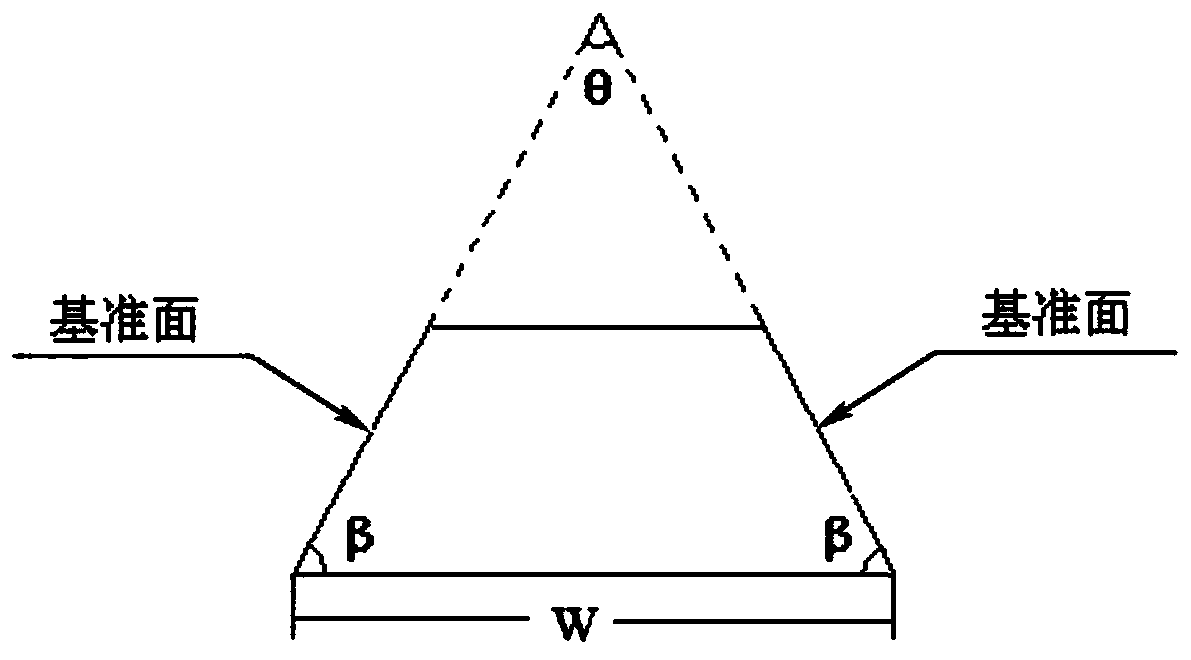

A surface measurement and blade technology, applied in the field of blade profile measurement and clamping devices, can solve the problems of low positioning accuracy, low clamping efficiency, manual blade adjustment, etc., achieve high repeat positioning accuracy, improve measurement accuracy, and benchmark accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific blade measurement cases:

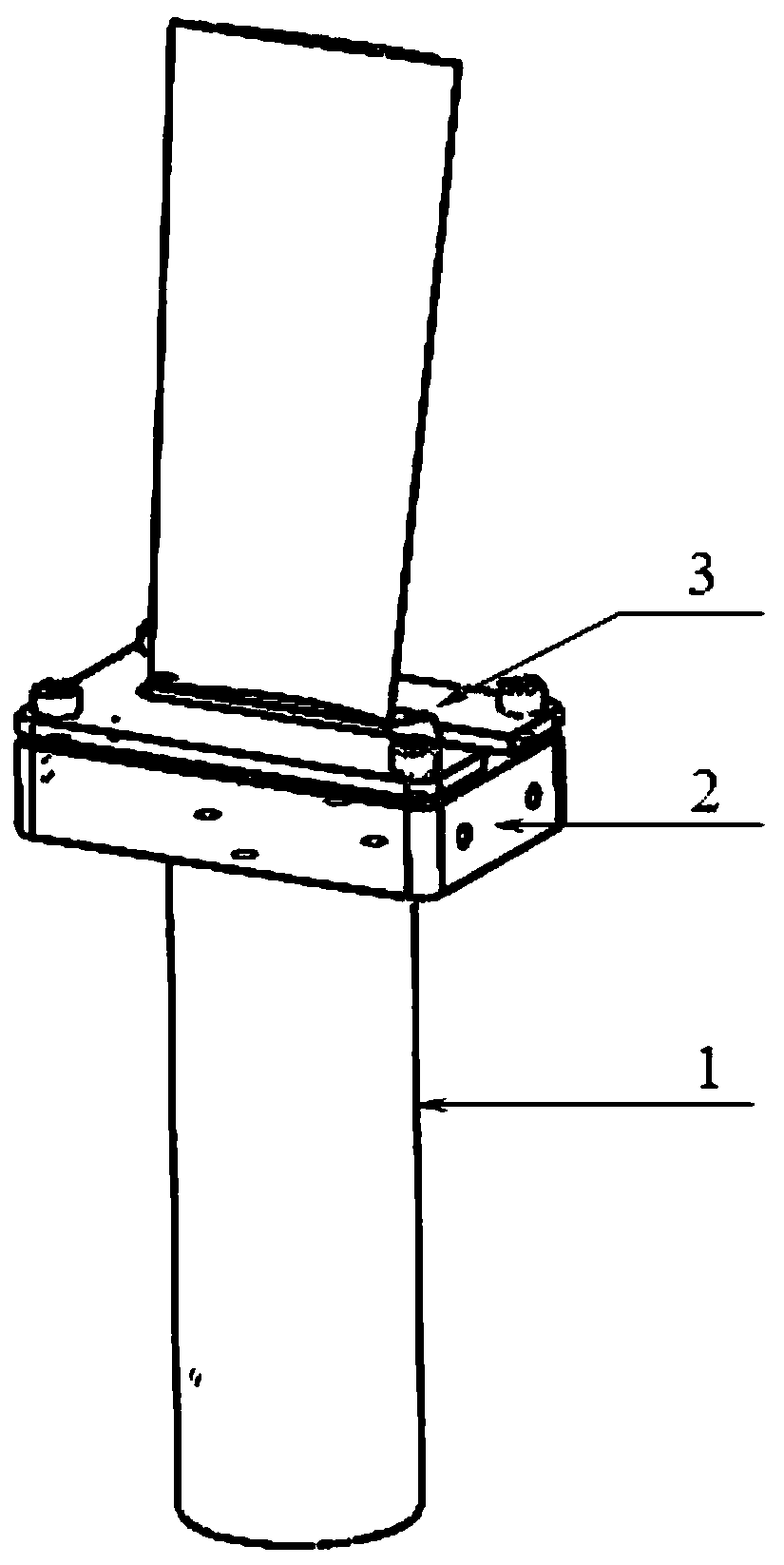

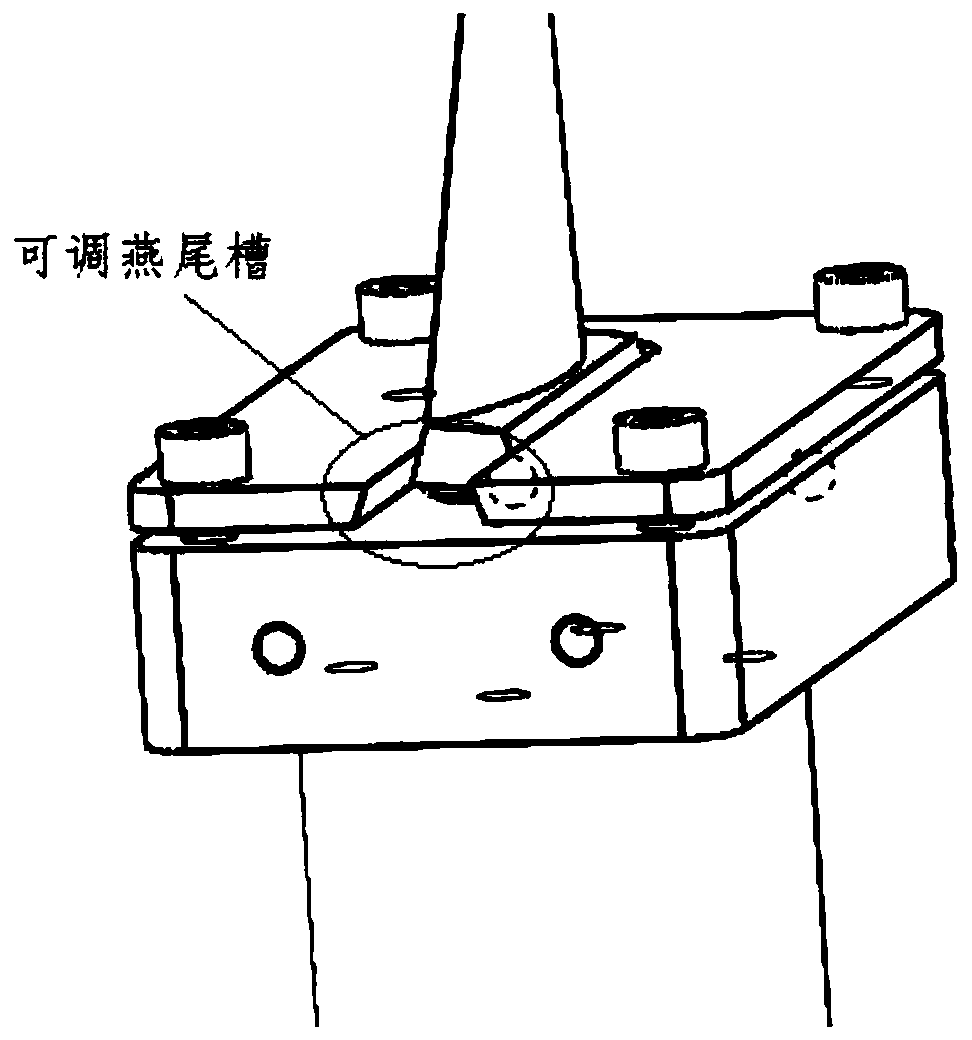

[0036] refer to figure 2 , a clamping device for blade profile measurement, the device is composed of three parts: a mounting column 1, an abutment 2 and a blade pressing plate 3.

[0037] refer to Figure 4 , The mounting column 1 is provided with a support surface a101, a support surface b102, an installation cavity 103 extending into the installation column, a fastening screw 104 and four installation holes a105 for connecting the abutment 2. The mounting column is set on the lower thimble of the rotary platform of the measuring instrument through the mounting cavity to realize the connection between the measuring system and the blade clamping device, and is fixed by the fastening screw 104 on the cavity. In addition, the mounting column also has the function of adjusting the height of the blade and providing a measurement reference.

[0038] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com