An auxiliary fiber arrangement device for optical fiber surround system

An optical fiber and winding technology, which is applied in the field of optical fiber winding auxiliary fiber arrangement device, can solve the problems of poor uniformity of pressure distribution, low efficiency, and low degree of winding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

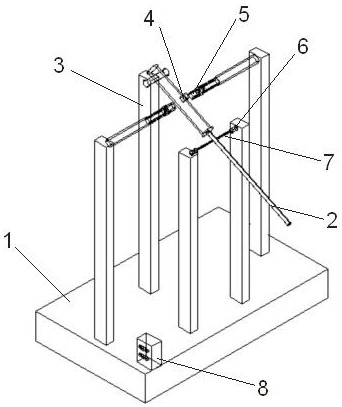

[0022] Example: see figure 1 , an optical fiber surround system auxiliary fiber arrangement device, including a frame 1, a fiber arrangement rod 2 and a counterweight 4. One end of the fiber rod 2 is rotatably connected to the frame 1, and the other end is a T-shaped compression head; wherein, the frame 1 has a row of fiber rod pillars 3, and the fiber rod 2 and the The pillar 3 is rotatably connected. The counterweight 4 is an iron block and is installed on the fiber rod 2 , and the counterweight 4 is close to the end of the fiber rod 2 connected to the pillar 3 .

[0023] There are two electromagnets 5 symmetrically distributed on the left and right sides of the counterweight 4: electromagnet Ⅰ and electromagnet Ⅱ, and the two electromagnets 5 are located on the same horizontal plane; among them, the electromagnet Ⅰ is located on the left side of the fiber rod 2, and the electromagnet Ⅱ It is located on the right side of fiber rod 2. There are two tension sensors 6 symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com