A radiation-resistant polarization-maintaining optical fiber and its preparation method and application

A polarization-maintaining optical fiber and radiation-resistant technology, which is applied in the direction of polarized optical fiber, clad optical fiber, glass manufacturing equipment, etc., can solve the problems of not being resistant to radiation, achieve good full-temperature characteristics, ensure batch consistency, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

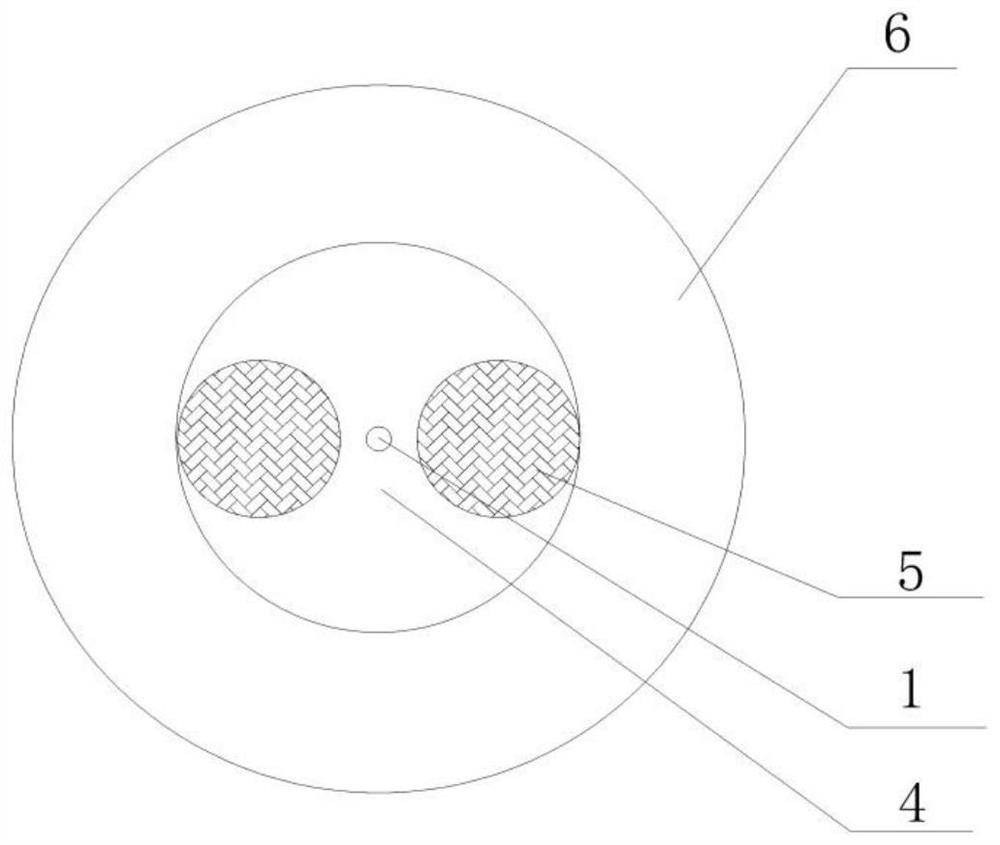

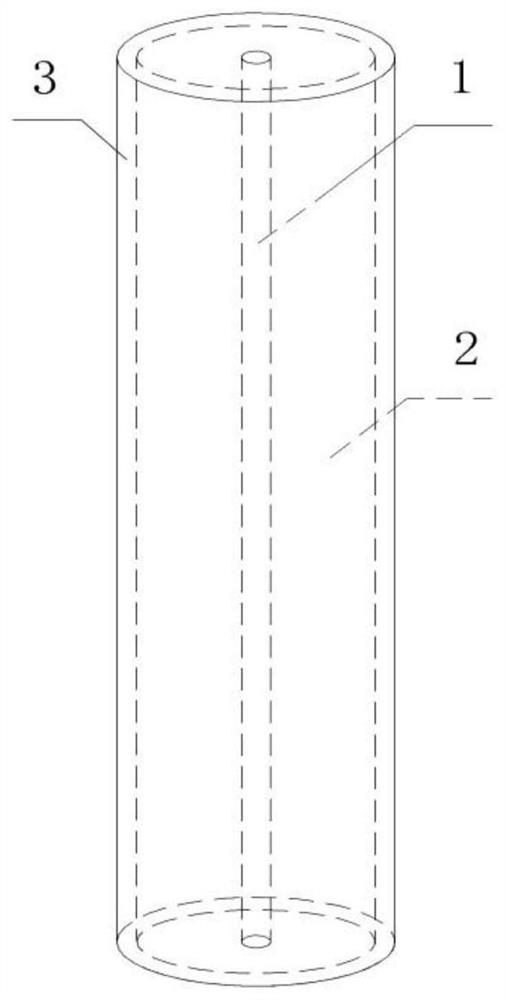

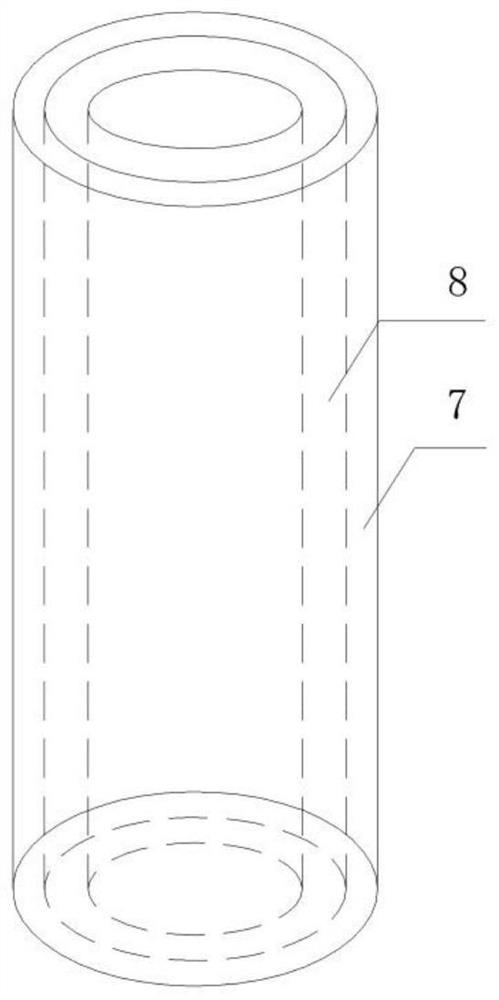

[0053] Such as Figure 1 to Figure 6 As shown, in this embodiment, the PCVD process is first used to prepare a core rod of pure silica liner, first cladding inner layer, and pure silica core from the outside to the inside, and the doping composition is B 2 o 3 Stress rods, and the fluorine-doped tubes of the first cladding outer layer and the pure quartz liner from the inside to the outside, wherein the first cladding inner layer and the first cladding outer layer are completely consistent in composition, in order to make the second The inner layer of the first cladding is in contact with the outer layer of the first cladding, the pure quartz liner outside the core rod is removed by grinding, and the pure quartz liner outside the fluorine-doped tube is retained. Then insert the core rod into the fluorine-doped tube and melt at 2000°C to form a fluorine-doped solid rod. The diameter of the fluorine-doped solid rod is 25 mm. The inner layer of the first cladding and the outer l...

Embodiment 2

[0058] Such as Figure 1 to Figure 6 As shown, in this embodiment, the PCVD process is first used to prepare a core rod of pure silica liner, first cladding inner layer, and pure silica core from the outside to the inside, and the doping composition is B 2 o 3 Stress rods, and the fluorine-doped tubes of the first cladding outer layer and the pure quartz liner from the inside to the outside, wherein the first cladding inner layer and the first cladding outer layer are completely consistent in composition, in order to make the second The inner layer of the first cladding is in contact with the outer layer of the first cladding, the pure quartz liner outside the core rod is removed by grinding, and the pure quartz liner outside the fluorine-doped tube is retained. Then insert the mandrel into the fluorine-doped tube and melt at 2300°C to form a fluorine-doped solid rod. The diameter of the fluorine-doped solid rod is 30 mm. The inner layer of the first cladding and the outer la...

Embodiment 3

[0063] Such as Figure 1 to Figure 6 As shown, in this embodiment, the PCVD process is first used to prepare a core rod of pure silica liner, first cladding inner layer, and pure silica core from the outside to the inside, and the doping composition is B 2 o 3 Stress rods, and the fluorine-doped tubes of the first cladding outer layer and the pure quartz liner from the inside to the outside, wherein the first cladding inner layer and the first cladding outer layer are completely consistent in composition, in order to make the second The inner layer of the first cladding is in contact with the outer layer of the first cladding, the pure quartz liner outside the core rod is removed by grinding, and the pure quartz liner outside the fluorine-doped tube is retained. Then insert the mandrel into the fluorine-doped tube and melt at 2100°C to form a fluorine-doped solid rod. The diameter of the fluorine-doped solid rod is 35 mm. The inner layer of the first cladding and the outer la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com