An optical fiber f-p strain gauge based on mems technology and its forming method

A technology of F-P and strain gauge, which is applied in the process of producing decorative surface effect, metal material coating process, photoplate making process of patterned surface, etc. Further improve the measurement resolution and other issues to achieve the effects of avoiding interference spectrum degradation, wide operating temperature range, and ensuring batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

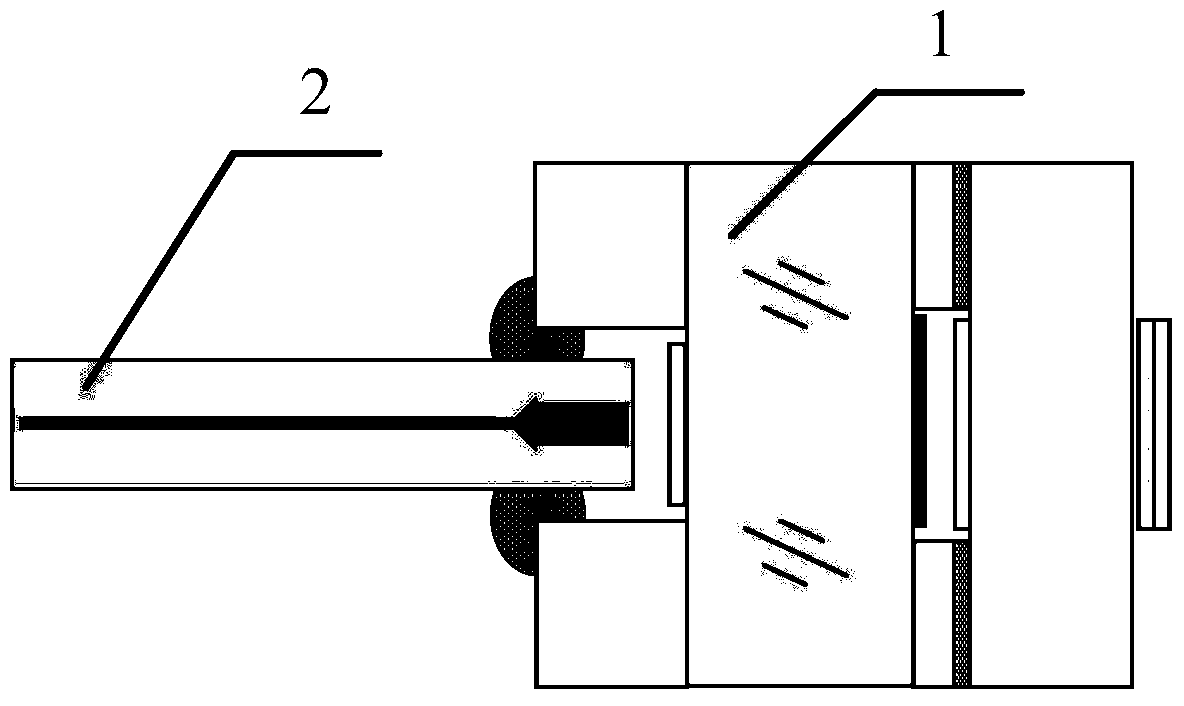

[0054] A structural schematic diagram of an optical fiber F-P strain gauge based on MEMS technology is shown in figure 1 As shown, the optical fiber F-P strain gauge mainly includes a F-P strain-sensitive MEMS chip 1 and a collimated beam expanding optical fiber 2;

[0055] Wherein, the structure schematic diagram of F-P strain-sensitive MEMS chip 1 is shown in Figure 2, and described F-P strain-sensitive MEMS chip 1 is made up of SOI strain beam, glass fixed pole 3 and silicon casing 4;

[0056] The SOI strain beam includes a top layer of silicon 5, an intermediate oxide layer 6, and a bottom layer of silicon 7; wherein, a patterned anti-reflection film 8 and a passivation layer 10 are deposited on one side of the bottom layer of silicon 7, and a highly reflective coating is deposited on the other side. Membrane 9; both the middle oxide layer 6 and the top layer of silicon 5 are processed with central holes, the central holes are coaxial and have the same diameter;

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com