Predication method for corrosion service life of metal material

A metal material and life prediction technology, which is applied in the direction of analysis materials, weather resistance/light resistance/corrosion resistance, measuring devices, etc., can solve problems such as difficult corrosion prediction research, and achieve good prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

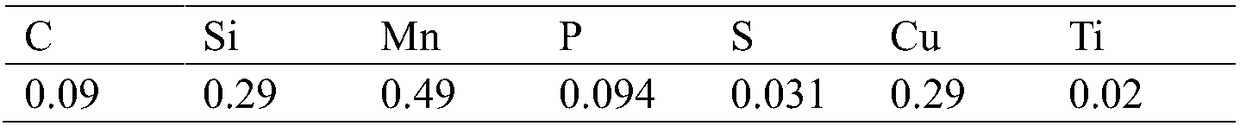

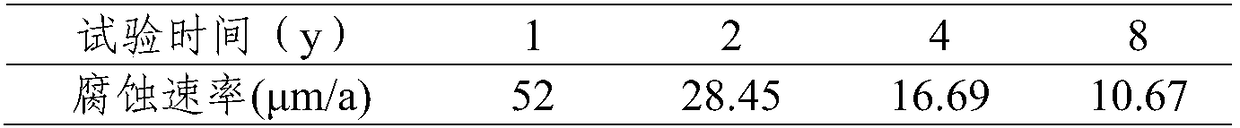

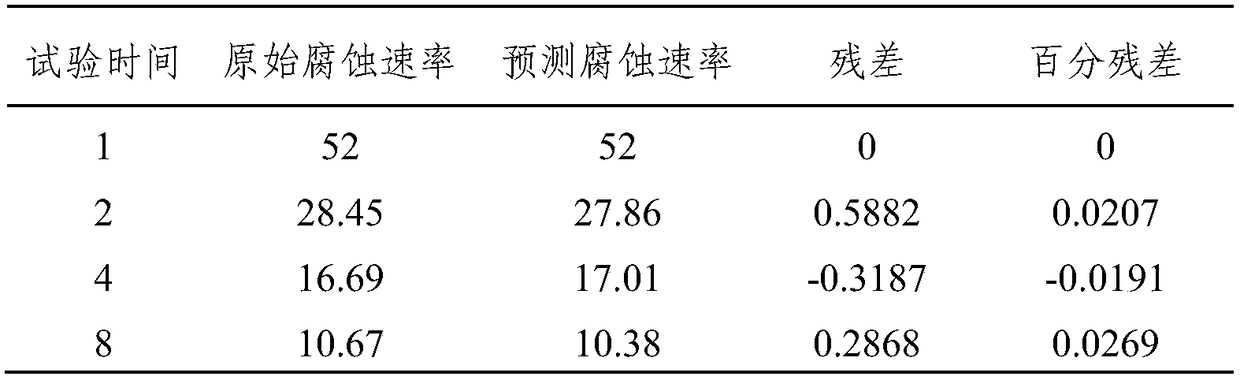

[0025] From 1983 to 1993, a 10-year corrosion test of weathering steel was carried out in Wuhan area. The test steel is 09CuPTi weathering steel, and its chemical composition is shown in Table 1. The test method is carried out according to GB / T14165- "General Requirements for Field Tests of Atmospheric Corrosion Tests of Metals and Alloys". The test material faces south and is tested at an angle of 45° to the ground. After the samples exposed for different periods were taken back, they were derusted with derusting solution. After derusting, they were rinsed with distilled water and dried in cold air, then weighed, and the corrosion loss weight was calculated, as shown in Table 2.

[0026] Table 1 Chemical composition of 09CuPTi weathering steel

[0027]

[0028] Table 2 Corrosion test data of weathering steel

[0029]

[0030] Let X 0 (t) is the corrosion rate of weathering steel, then the original sequence is:

[0031] x 0 (t) = {52, 28.45, 16.69, 10.67}.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com