Silicon wafer inserting device, silicon wafer cleaning equipment and silicon wafer cleaning method

A technology for silicon wafer insertion and silicon wafer cleaning, applied in transportation and packaging, conveyor objects, sustainable manufacturing/processing, etc., can solve the problems of poor cleaning effect and prolong cleaning time, so as to improve cleaning efficiency and reduce Cleaning time, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

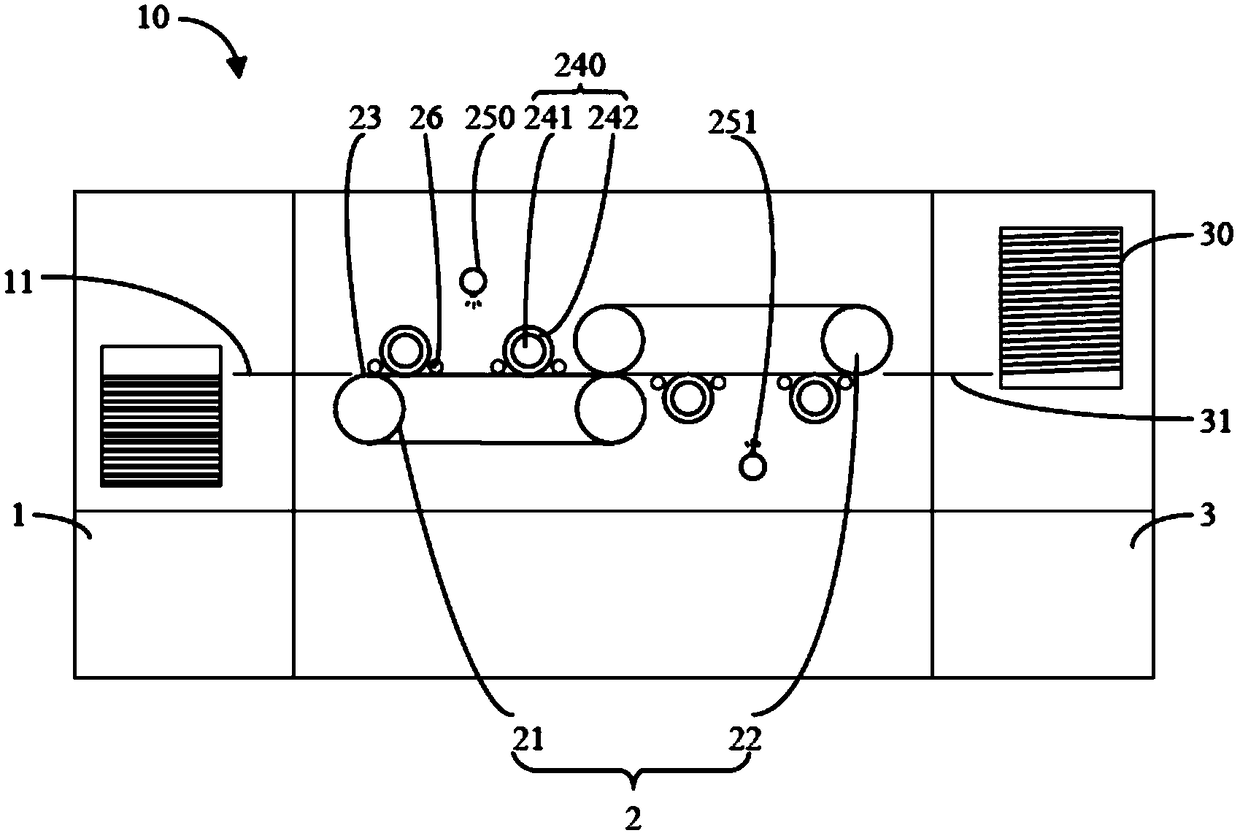

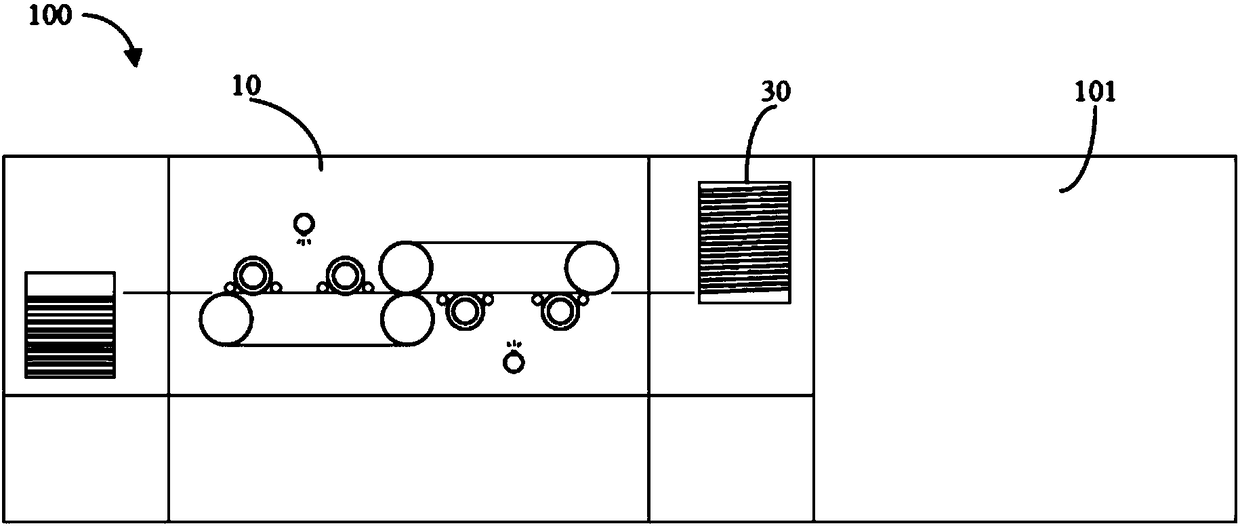

[0028] see figure 1 , The first embodiment of the present invention provides a silicon wafer inserting device 10 , including a loading unit 1 , a cleaning unit 2 and a wafer inserting unit 3 which are connected. The feeding unit 1 transfers the silicon wafers to the inserting unit 3 one by one. The cleaning unit 2 is located between the loading unit 1 and the insertion unit 3 , and cleans the silicon wafers before entering the insertion unit 3 .

[0029] The feeding unit 1 has a feeding conveying unit 11 communicating with the cleaning unit 2 . The loading unit 1 can be a loading structure in the prior art, and the silicon wafers are transferred to the loading and conveying unit 11 one by one.

[0030] The cleaning unit 2 includes at least one cleaning section. Specifically, the cleaning unit 2 may include a plurality of cleaning sections ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com