Adaptable special-shaped liner tube

A liner and variation technology, which is applied in the field of high-voltage, ultra-high-voltage and ultra-high-voltage hollow composite insulators in power systems, can solve the problem that pultruded glass fiber pipes cannot be lined with steel liners, time and speed are inconsistent, and it is difficult to apply hollow pillars Composite insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

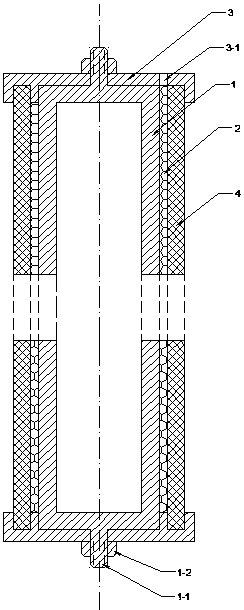

[0010] With reference to the accompanying drawings, the seamless steel pipe is turned into a steel liner 1 whose outer diameter is appropriately smaller than the inner diameter of the lined pultruded glass fiber tube. The end caps 3 are processed with steel plates, and one of the end caps is provided with a filling hole 3-1.

[0011] Place the pultruded fiberglass tube 4 to be lined on the straightening device for straightening, insert the steel liner 1, install the end caps 3 at both ends, and tighten the nuts 1-2.

[0012] Vertically erect the pultruded glass fiber tube together with the straightening device, with the end of the filling hole 3-1 facing upwards, pour solid particles 2 into the filling hole, and vibrate the glass fiber tube with a vibrator while filling, so that The solid particles 2 are dense and close to the inner wall of the pultruded glass fiber tube 4 and the outer wall of the steel liner 1 . Close the filling hole after filling. At this time, the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com