Substrate handling equipment and heat shields

A substrate processing device and heat shield technology, which is applied to discharge tubes, electrical components, circuits, etc., can solve problems such as increased radiated heat, and achieve the effect of preventing heat accumulation

Active Publication Date: 2019-12-24

TOKYO ELECTRON LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in the ion trap facing the plasma, there are many ions colliding with the central part. If chemical etching treatment is repeated, for example, a lot of heat is accumulated in the central part of the ion trap. The central part of the collector faces the process space, and the radiant heat of the wafer increases

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0062] Next, examples of the present invention will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

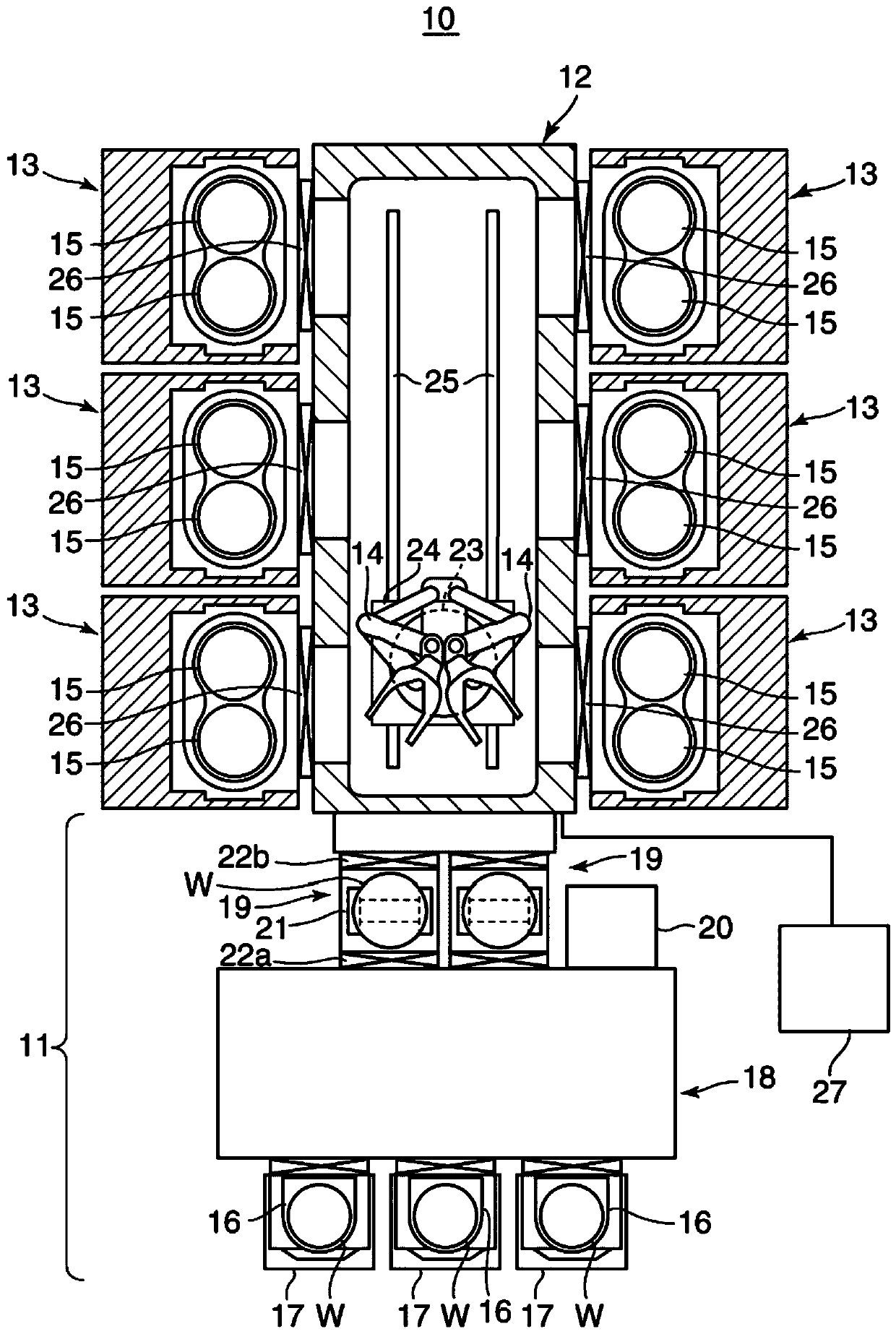

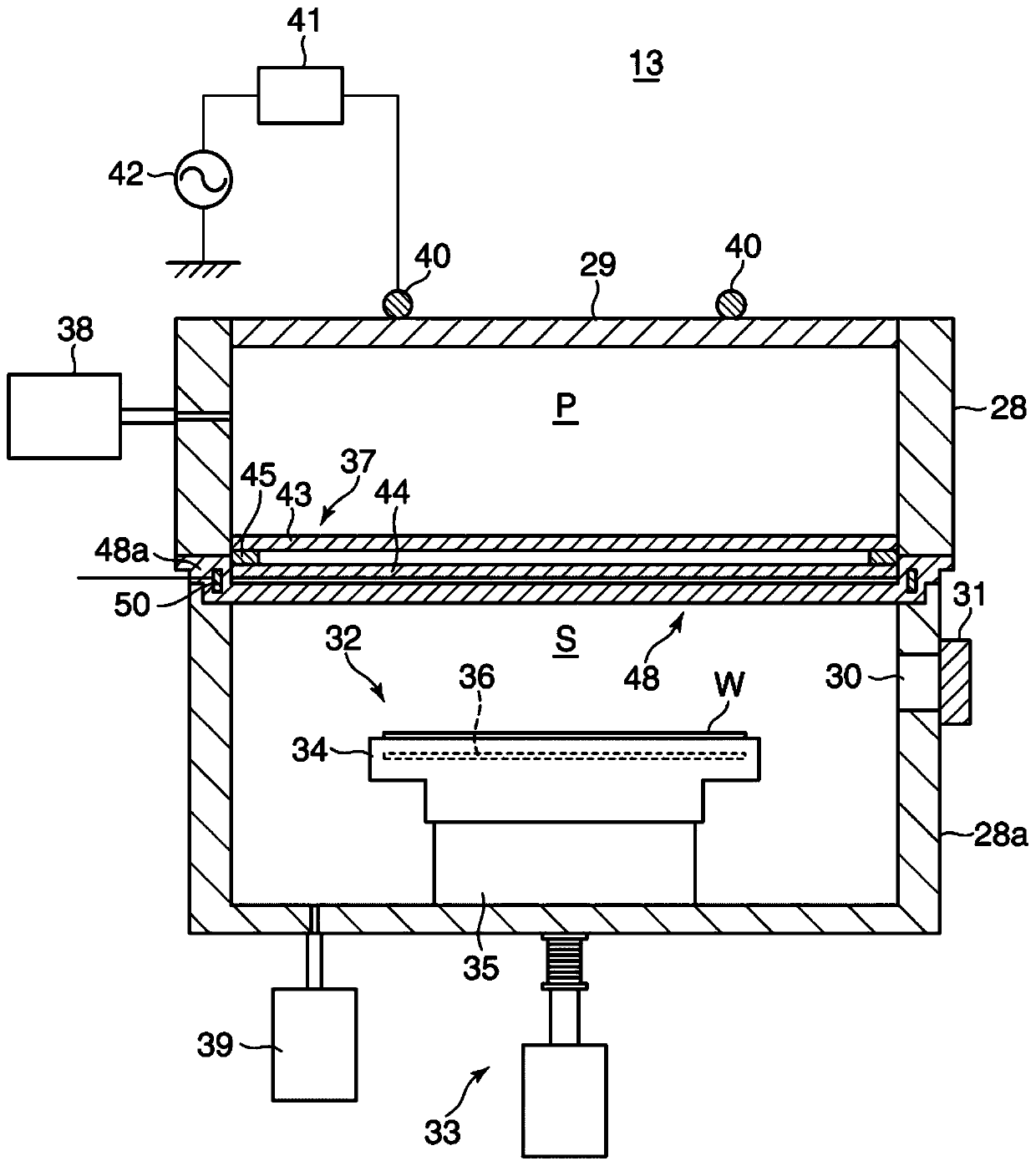

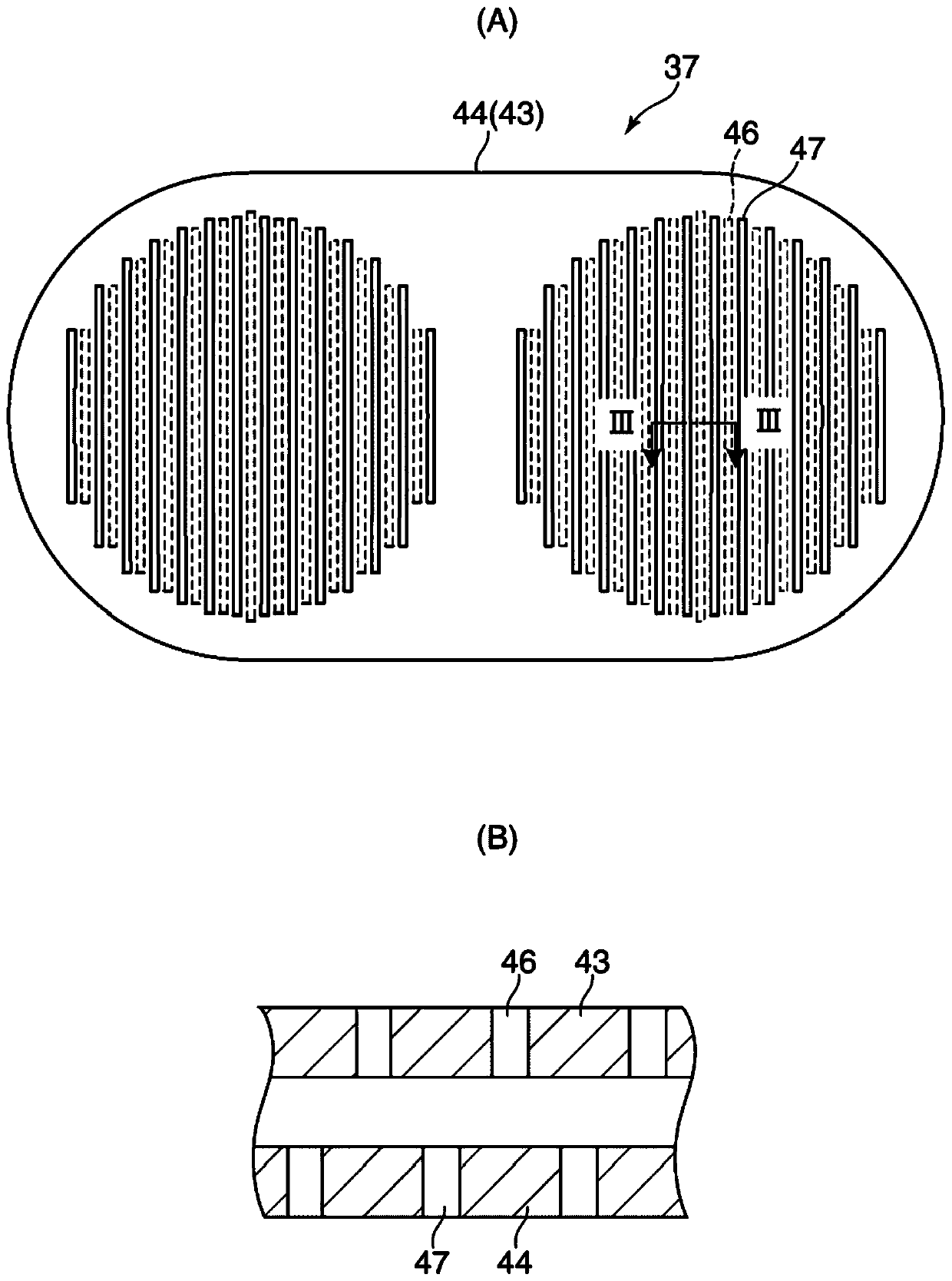

The invention provides a substrate processing device and a heat shield. The substrate processing apparatus can uniformly perform processing using radicals on a substrate even when processing is repeated. The process module (13) has: a processing container (28) for accommodating the wafer (W); (W); a heat shield (48), which is configured between the partition plate (37) and the wafer (W), and the partition plate (37) is selectively placed in the plasma generation space (P) Radicals in the generated plasma permeate toward the wafer (W), and the heat shield (48) is arranged in a manner facing the wafer (W). )connect.

Description

technical field [0001] The present invention relates to a substrate processing apparatus that processes a substrate using radicals in plasma, and a heat shield suitable for the substrate processing apparatus. Background technique [0002] In recent years, it has been proposed to chemically etch a semiconductor wafer (hereinafter simply referred to as “wafer”) as a substrate using radicals in plasma (see, for example, Patent Document 1). [0003] Such an apparatus for performing chemical etching treatment includes a plate-shaped ion trap that is interposed between the plasma and the wafer in the processing chamber, and controls the movement of ions in the plasma toward the wafer. inhibition. The ion trap has many slits penetrating in the thickness direction, blocks the movement of ions moving anisotropically, and transmits radicals moving isotropically through the labyrinth of the plurality of slits. As a result, almost only free radicals exist in the processing space facin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01J37/32

CPCH01J37/32522H01L21/31116H01L21/67103H01L21/6719H01J37/321H01J37/32357H01J37/32422H01J2237/334H01L21/67069H01L21/6835H01J2237/3174H01L21/3065

Inventor 小川裕之清水昭贵土场重树

Owner TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com