Partially graphitized activated carbon-based composite additive and preparation, negative electrode and application

A composite additive, activated carbon technology, applied in battery electrodes, lead-acid battery electrodes, structural parts, etc., can solve the problem of not changing the electronic conductivity of activated carbon particles, reduce energy consumption and water consumption, simplify the preparation process, high The effect of charge-discharge reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

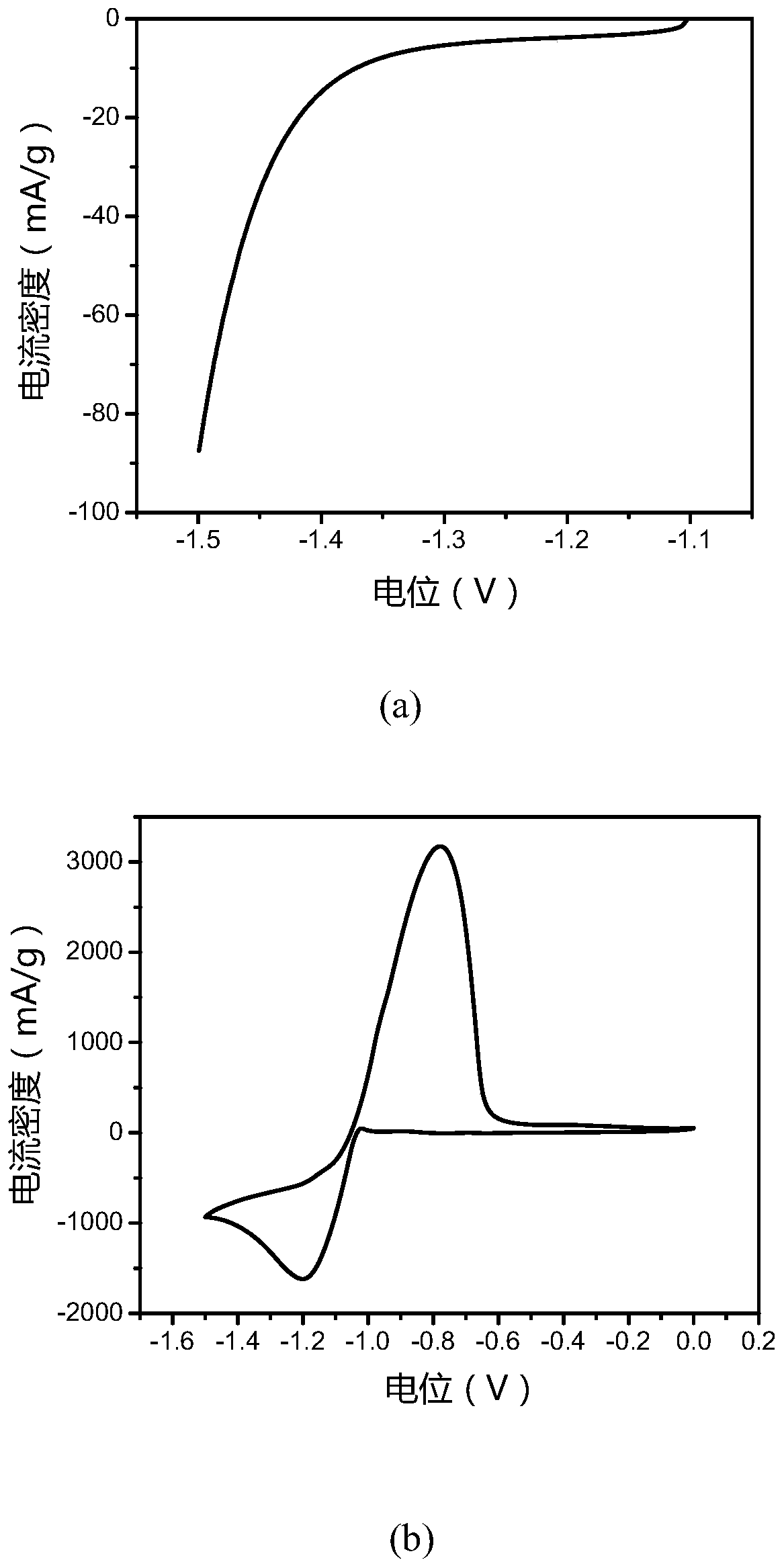

Embodiment 1

[0043] Weigh 0.078g of lead nitrate and add it into 4ml of deionized water, and stir until fully dissolved to obtain a lead nitrate solution. Weigh 1 g of activated carbon, add it into the above-mentioned lead nitrate solution and stir evenly to obtain a slurry. Then, 0.069 g of sulfuric acid having a density of 1.245 g / ml (25° C.) was slowly dropped into the slurry while stirring. The resulting mixture was dried at 85 °C for 20 h to obtain the activated carbon precursor powder deposited with lead sulfate. Put the above precursor powder in N 2 Calcined at 600°C for 2 hours in a protective atmosphere to obtain lead-poisoned partially graphitized activated carbon. 10g of lead powder, 0.15g of lead-poisoned partially graphitized activated carbon, 0.14g of barium sulfate, and 0.005g of short polypropylene fibers with a length of 5mm were premixed with a high-speed mixer. 1.4 g of deionized water was then added to the premixed powder with stirring. After stirring evenly, slowly...

Embodiment 2

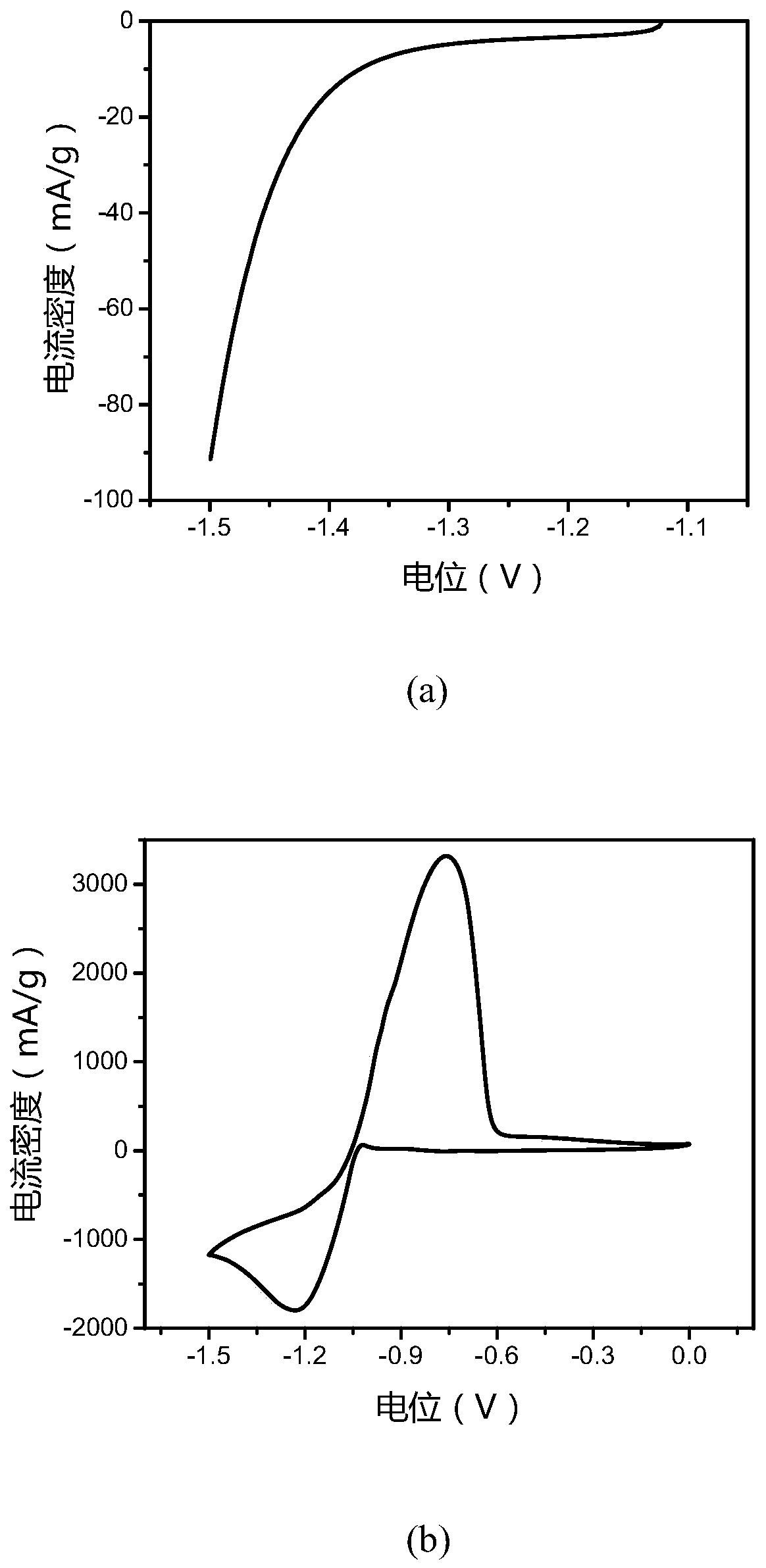

[0045] Weigh 0.078g of lead nitrate and add it into 4ml of deionized water, and stir until fully dissolved to obtain a lead nitrate solution. Weigh 1 g of activated carbon, add it into the above-mentioned lead nitrate solution and stir evenly to obtain a slurry. Then, 0.069 g of sulfuric acid having a density of 1.245 g / ml (25° C.) was slowly dropped into the slurry while stirring. The resulting mixture was dried at 85 °C for 20 h to obtain the activated carbon precursor powder deposited with lead sulfate. Put the above precursor powder in N 2 Calcined at 700°C for 2 hours in a protective atmosphere to obtain lead-poisoned partially graphitized activated carbon. 10g of lead powder, 0.15g of lead-poisoned partially graphitized activated carbon, 0.14g of barium sulfate, and 0.005g of short polypropylene fibers with a length of 5mm were premixed with a high-speed mixer. 1.4 g of deionized water was then added to the premixed powder with stirring. After stirring evenly, slowly...

Embodiment 3

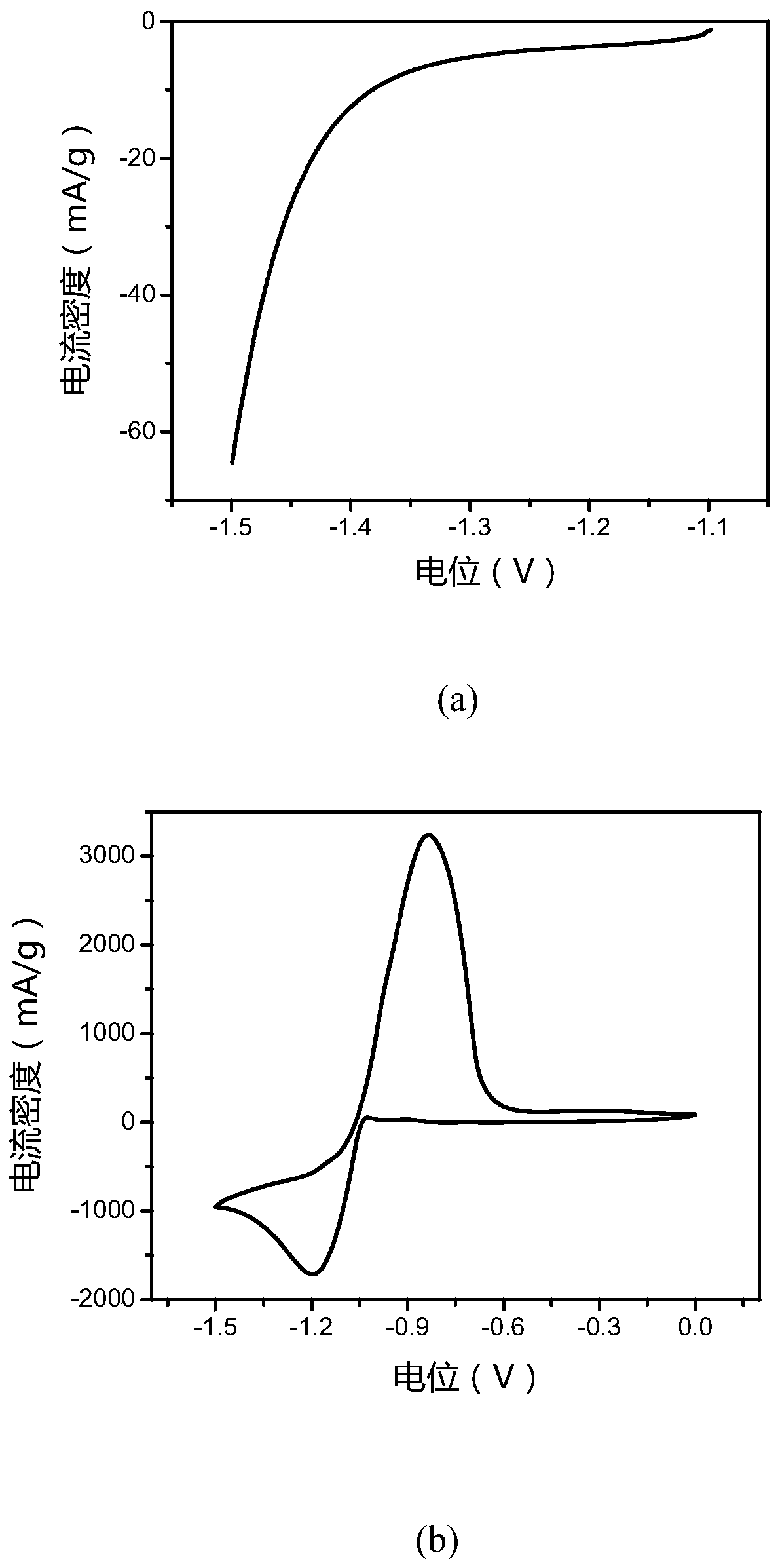

[0047] Weigh 0.078g of lead nitrate and add it into 4ml of deionized water, and stir until fully dissolved to obtain a lead nitrate solution. Weigh 1 g of activated carbon, add it into the above-mentioned lead nitrate solution and stir evenly to obtain a slurry. Then, 0.069 g of sulfuric acid having a density of 1.245 g / ml (25° C.) was slowly dropped into the slurry while stirring. The resulting mixture was dried at 85 °C for 20 h to obtain the activated carbon precursor powder deposited with lead sulfate. Put the above precursor powder in N 2 Calcined at 800°C for 2 hours in a protective atmosphere to obtain lead-poisoned partially graphitized activated carbon. 10g of lead powder, 0.15g of lead-poisoned partially graphitized activated carbon, 0.14g of barium sulfate, and 0.005g of short polypropylene fibers with a length of 5mm were premixed with a high-speed mixer. 1.4 g of deionized water was then added to the premixed powder with stirring. After stirring evenly, slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com