Zero-setting device and zero-setting method for anemoscope of large semi-direct-drive unit

An anemometer and semi-direct drive technology, which is applied in the field of the zero-setting device of the anemometer of the large semi-direct drive unit, can solve the problem of affecting the power generation of the unit, the fan cannot be accurately aligned with the incoming wind direction, and the power curve of the generator unit is shifted to the right, etc. problems, to reduce the risk of inaccurate wind, eliminate load imbalance, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific examples.

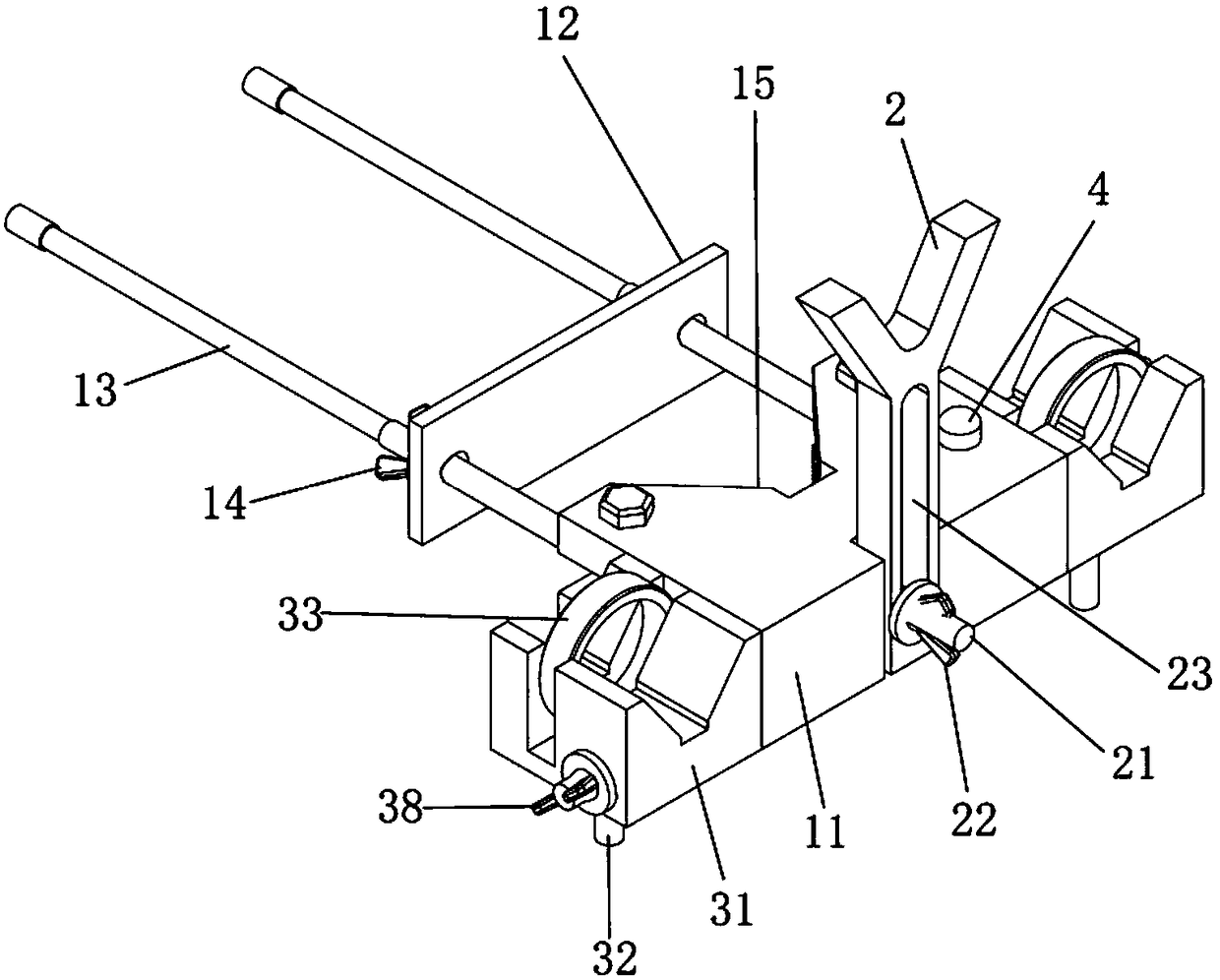

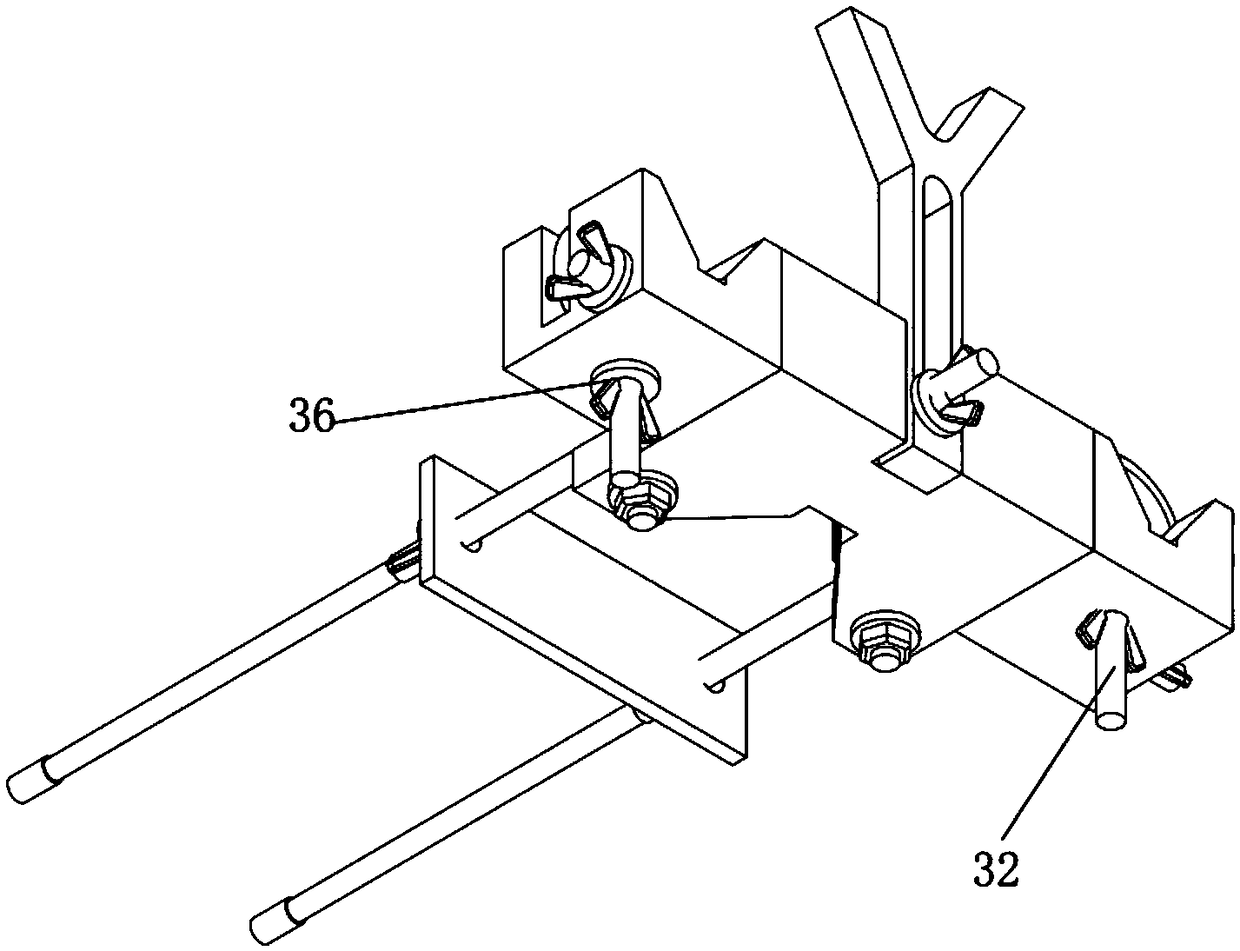

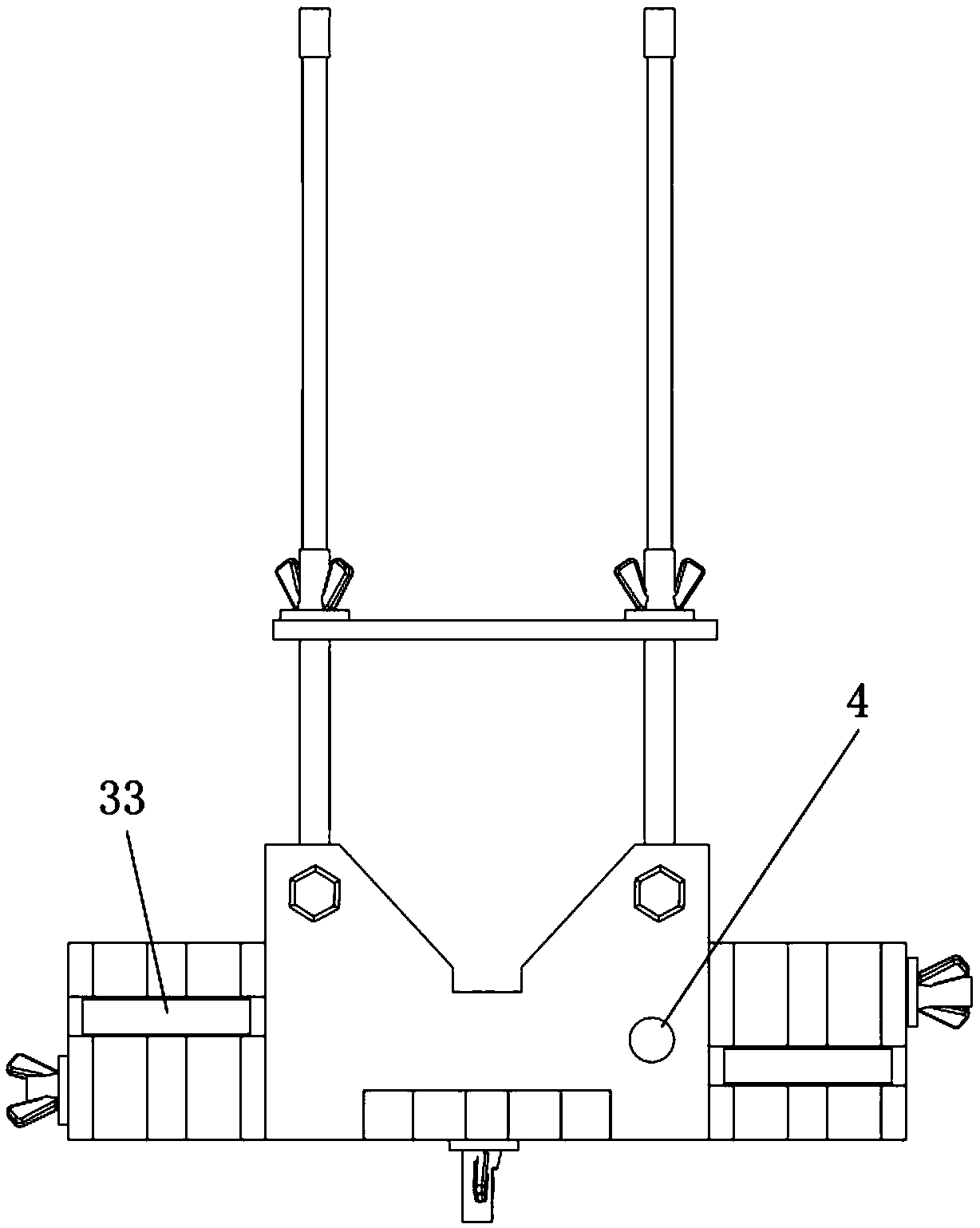

[0041] see Figure 1 to Figure 5 As shown, the zero-setting device for large-scale semi-direct-drive unit anemometer provided in this embodiment includes an anemometer main body clamping mechanism, anemometer counterweight limiting mechanism 2, anemometer laser pen limiting mechanism, a horizontal testing facility. The clamping mechanism of the main body of the anemometer includes a base body 11, a splint 12, a supporting screw rod 13 and a wing nut 14. The front end of the base body 11 has a V-shaped notch 15 for clamping the main body of the anemometer 5 ( That is, the middle cylindrical part of the anemometer), the screw 13 has two symmetrical and vertically installed on the front end of the base, and is located on both sides of the V-shaped notch 15, the splint 12 is sleeved on the two screw 13, can be along the The screw moves, and the base 11, splint 12, and two screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com