Medical polymer plate bending method

A polymer and sheet technology, applied in the field of sheet metal processing, can solve the problem of inaccurate angles of medical polymer sheets, and achieve the effects of avoiding inaccurate bending angles, uniform force, and accurate bending angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

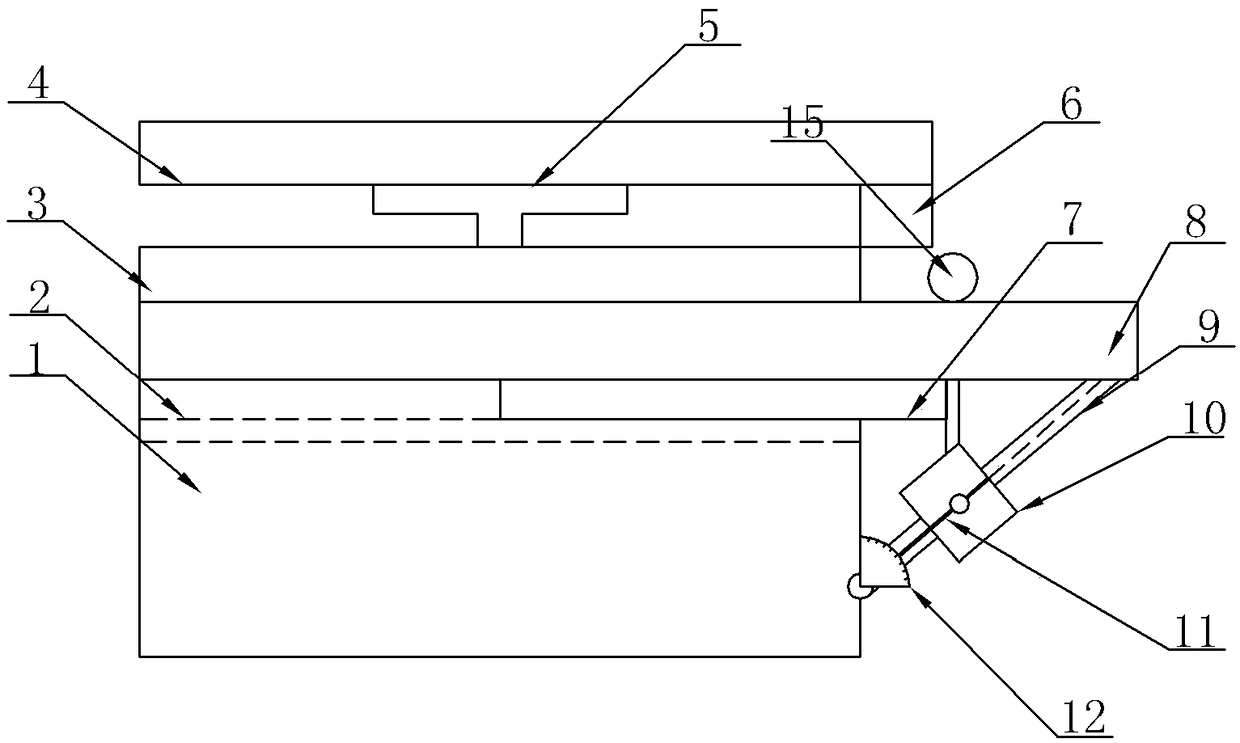

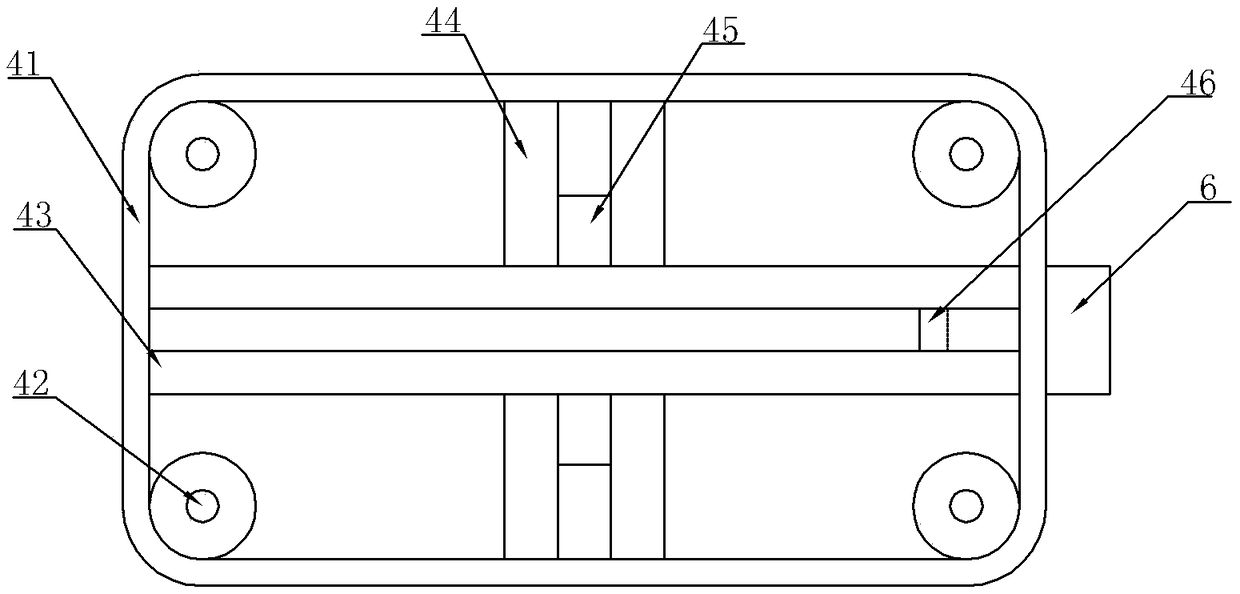

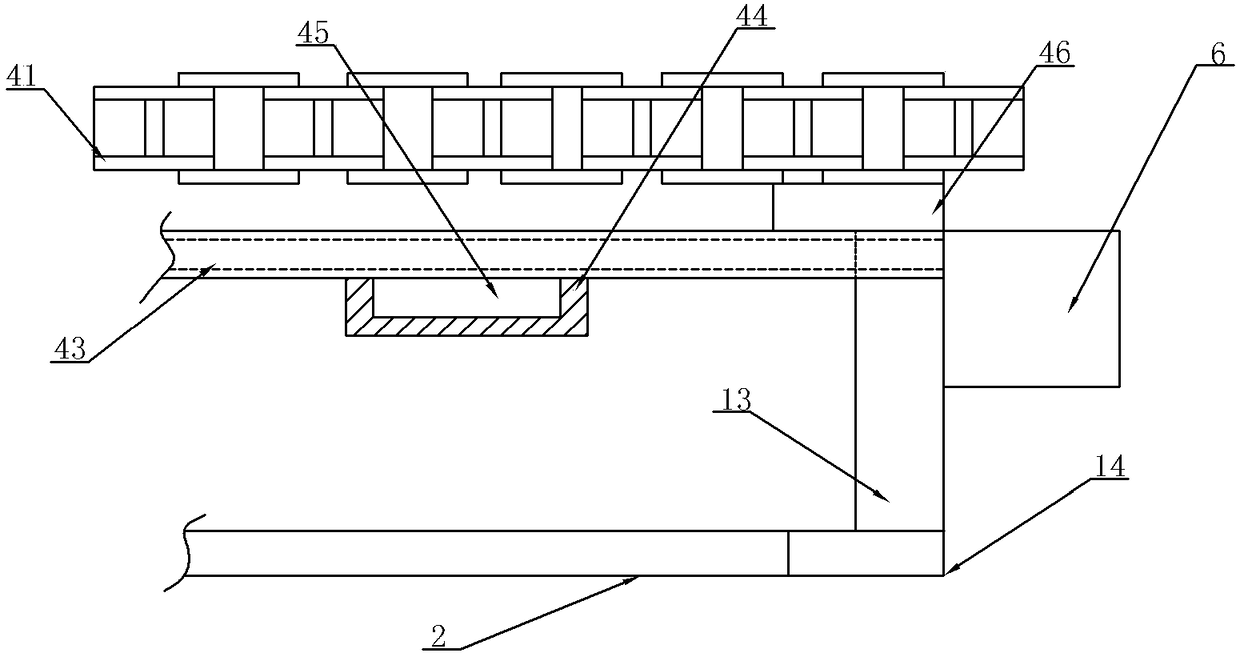

[0025] as attached figure 1 , attached figure 2 And attached image 3 As shown, a bending method of a medical polymer sheet uses a bending device, including a frame, a workbench 1 and a heating mechanism 4. The workbench 1 is fixed on the frame for stabilization, and the workbench 1 is provided with a ring The water channel 2, the water in the water channel 2 can preheat the plate 8. The top of the workbench 1 is provided with a first cylinder 5 and a compression plate 3 that is slidably connected with the frame and the compression plate 3 can slide vertically on the frame, the compression plate 3 is positioned under the first cylinder 5, and the first cylinder 5 is fixed on the frame by fastening bolts to avoid position deviation when the first cylinder 5 is working, and the first cylinder 5 pushes the pressing plate 3 to slide down to compress the plate 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com