Suede aluminum-plastic composite board as well as production process and production equipment thereof

A technology of aluminum-plastic composite panels and production equipment, which is applied in the field of aluminum-plastic composite panels, and can solve problems such as inconvenient adjustment of cutting discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

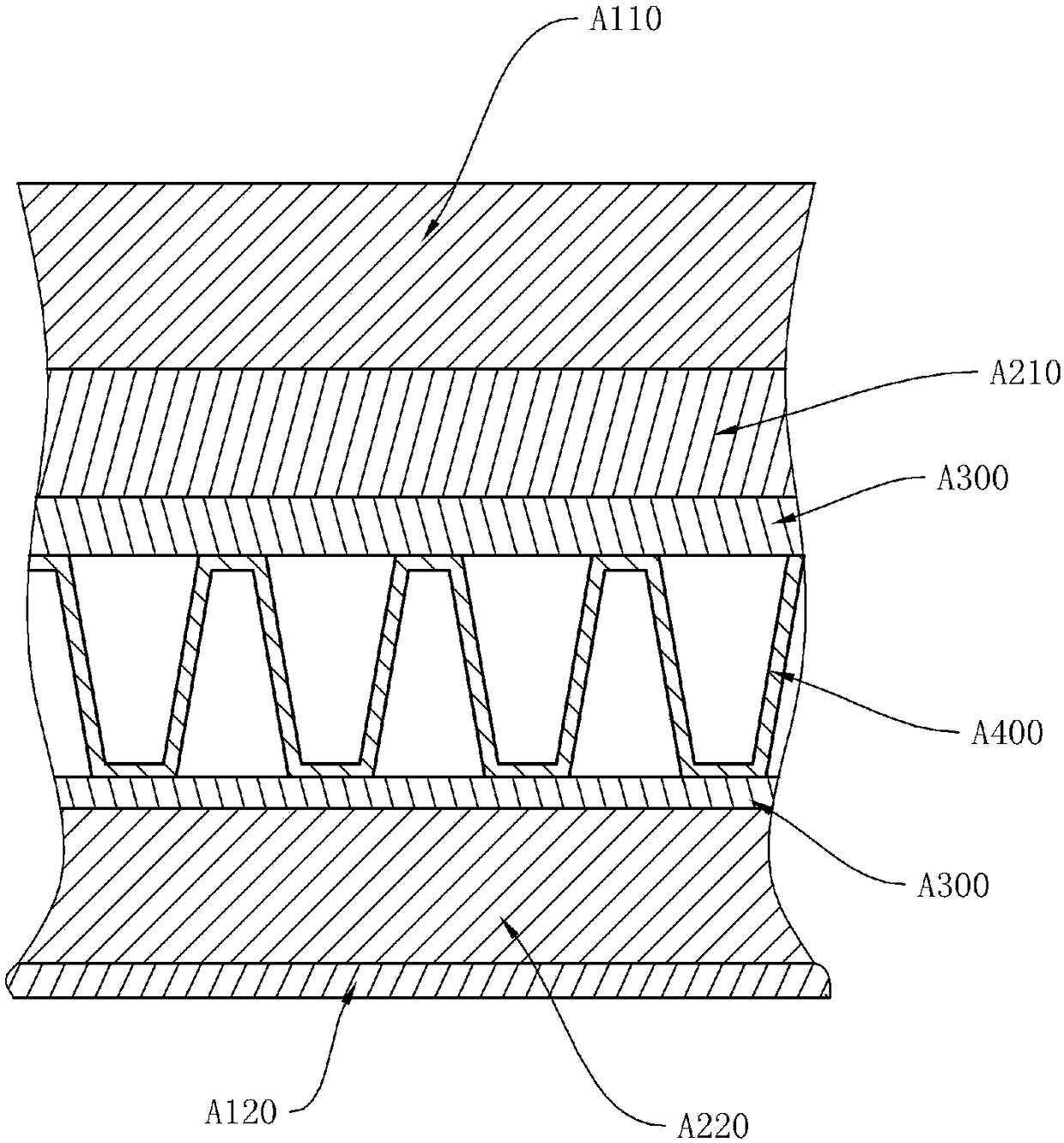

[0114] see figure 1 , a suede aluminum-plastic composite board, comprising a plastic board A400, the cross-section of the plastic board A400 is corrugated, and the two ends of the plastic board A400 are respectively bonded to the first aluminum board A210 and the second aluminum board A220 through the adhesive layer A300 fixed;

[0115] The top surface of the first aluminum plate A210 is provided with a suede layer A110, and the bottom surface of the second aluminum plate A220 is provided with a protective layer A120, and the protective layer can be a protective film or a polytetrafluoroethylene coating.

[0116] The undulating section of the plastic plate A400 may be trapezoidal, wavy or triangular.

[0117] The suede layer A110 is suede, which makes people feel warm and more decorative.

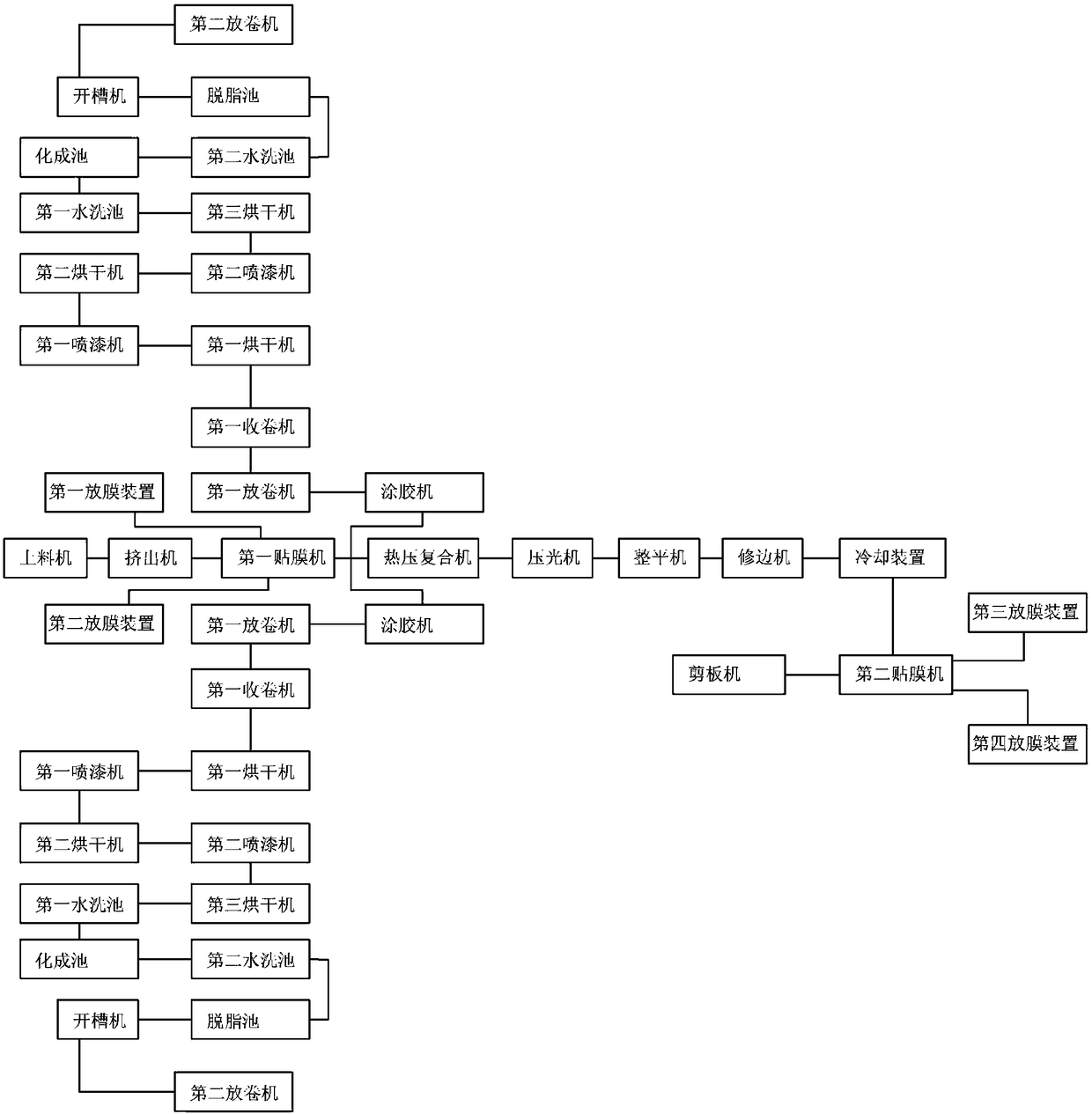

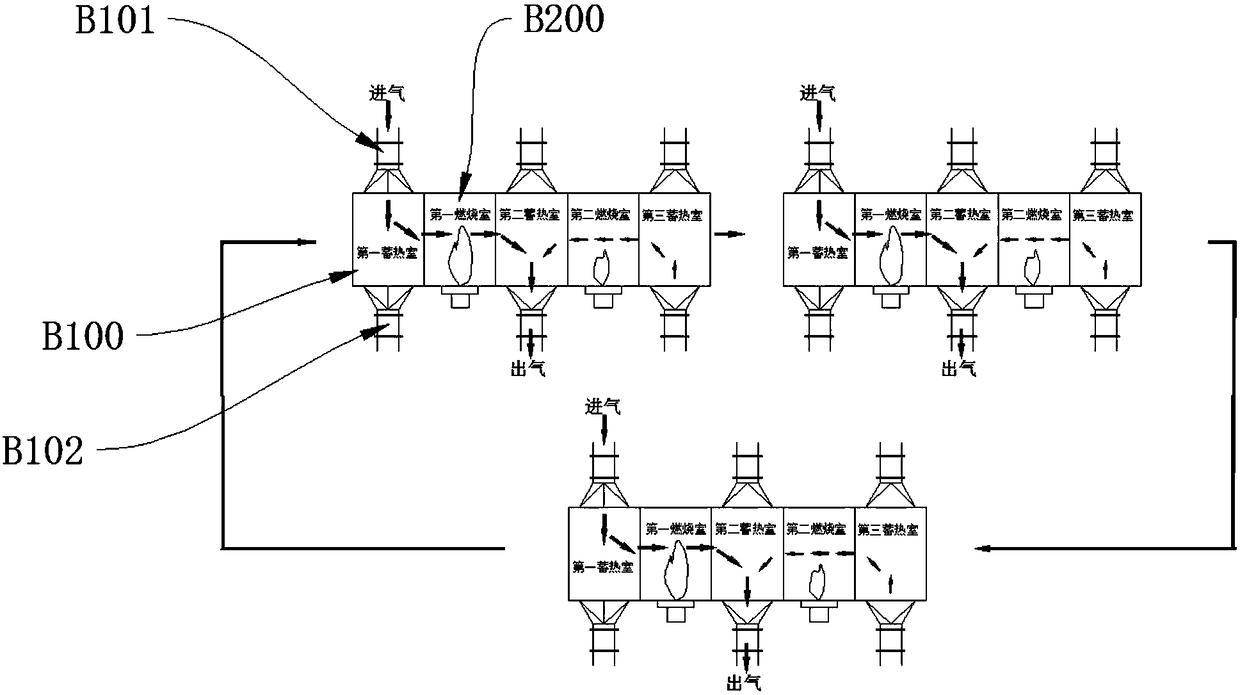

[0118] see figure 2 , a kind of production equipment of suede al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com