Distributed-type wheel-edge electrically-driven power assembly of electric vehicle and method

A technology for electric vehicles and powertrains, applied in the directions of electric powerplants, powerplants, vehicle components, etc., can solve the problems of increasing the difficulty of reducing gear powertrains, and achieve the advantages of avoiding large current discharge, easy installation and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings.

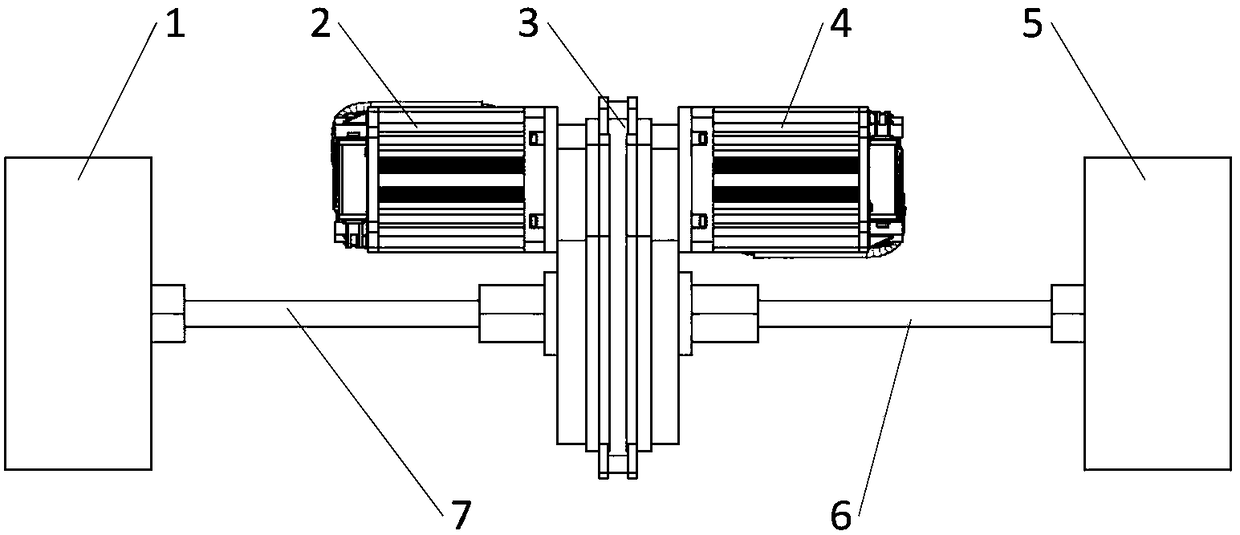

[0054] Refer to attached figure 1 , a distributed wheel-side electric drive powertrain for an electric vehicle, comprising a first wheel 1, a first motor 2, a two-in-one reducer 3, a second motor 4, a second wheel 5, and a second half-shaft assembly 6 , the first half shaft assembly 7. The two-in-one reducer 3 has two symmetrical gear reduction structures inside. The two structures do not interfere with each other and are only installed together through the housing. The two gear reduction structures are mirror images, and the input shafts and output shafts of the two gears are respectively arranged on both sides of the two-in-one reducer 3 . The first motor 2 and the second motor 4 are symmetrically arranged on the left and right sides of the two-in-one reducer 3, respectively, the first motor 2 is connected to the input shaft of the left gear reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com