Milk cow and live pig culturing farm manure low-cost high-efficiency fermentation processing system

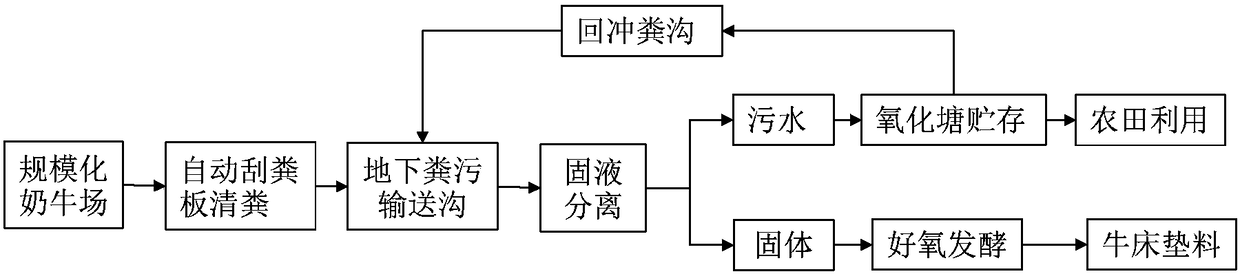

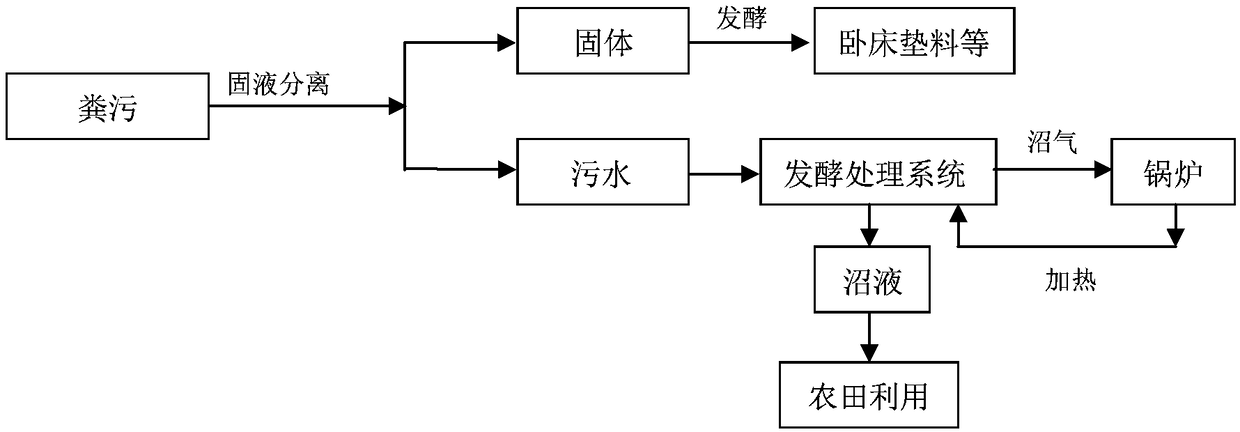

A treatment system and farm technology, applied in the field of low-cost and high-efficiency fermentation treatment system for cow and pig farm manure, can solve the problems of small contact area between biological filler and sewage, poor sewage treatment effect, poor fermentation effect, etc. Achieve the effects of thorough fermentation of sewage, improvement of sewage water quality, and improvement of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A farm with 1,000 dairy cows produces 40 tons of sewage per day

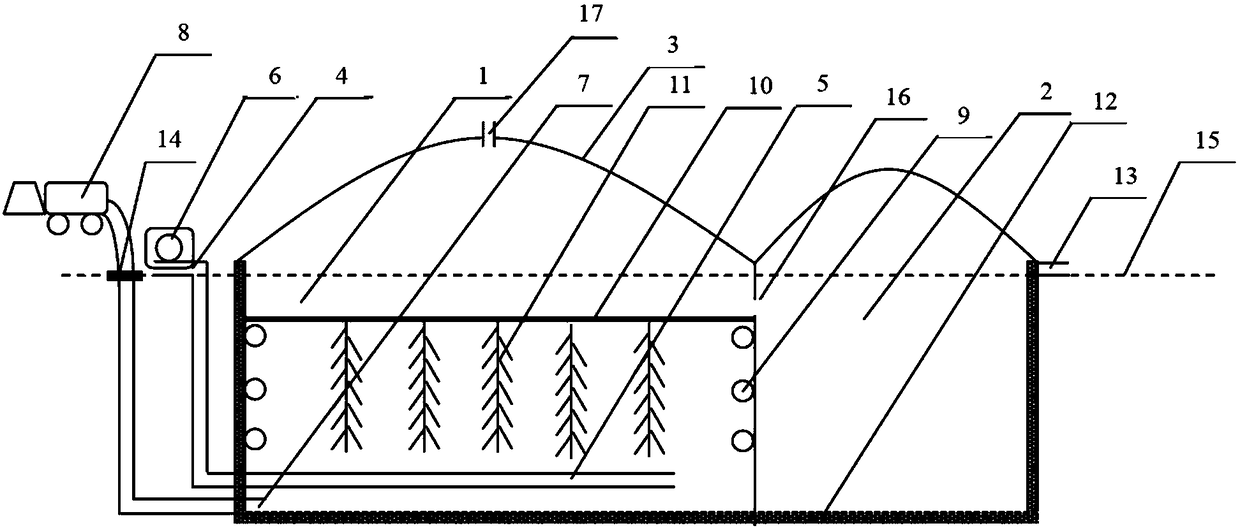

[0041] A low-cost and high-efficiency fermentation treatment system for feces from a dairy farm with 1,000 cows in stock. The fermentation treatment system includes a primary anaerobic pool 1 and a secondary anaerobic pool 2; the primary anaerobic pool 1 is a cuboid, with length × width × The height is 10m×10m×8m, and the total volume is 800m 3 , the secondary anaerobic pool 2 is also a cuboid, the length × width × height is 10m × 5m × 8m, and the total volume is 400m 3 , the primary anaerobic pool 1 is separated from the secondary anaerobic pool 2 by the pool wall, and the upper part of the pool wall is connected with the primary anaerobic pool 1 and the secondary anaerobic pool 2 by setting an overflow port 16, and the overflow port 16 Be arranged at the central position of pool wall length direction, overflow port 16 is rectangle, the distance of the upper end of overflow port 16 apart from the pool w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com