Furan dicarboxylic acid copolyester and preparation method and application thereof

A technology of furandicarboxylic acid copolyester and furandicarboxylic acid, which is applied in the polymer field to achieve the effects of good barrier properties, increased molecular weight and fast crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] After extensive and in-depth research, the present inventor has first discovered a furandicarboxylic acid copolyester and a preparation method thereof. The monomer that is used to prepare described furandicarboxylic acid copolyester comprises: component (a) furandicarboxylic acid or its esterification, component (b) cis-1,4-cyclohexanedimethanol (cis- CHDM) and trans-1,4-cyclohexanedimethanol (trans-CHDM) mixture, component (c) one or more of ethylene glycol, propylene glycol and butanediol. The furandicarboxylic acid copolyester with excellent properties was prepared through a series of reaction steps. On this basis, the present invention has been accomplished.

[0051] Furandicarboxylic acid copolyester

[0052] The furandicarboxylic acid copolyester of the present invention is made of component (a) furandicarboxylic acid or its esterification, component (b) cis-1,4-cyclohexanedimethanol (cis-CHDM) and trans Formula 1, 4-cyclohexanedimethanol (trans-CHDM) mixture, ...

Embodiment 1

[0069] Add 0.25mol of 2,5-furandicarboxylic acid, 0.32mol of ethylene glycol and 0.0004mol of anhydrous zinc acetate into a 1000mL reactor, vacuumize and replace with nitrogen three times, start stirring, and gradually raise the temperature to 180°C. 4h. Add antimony trioxide, triphenyl phosphate and antioxidant 1010 into the system, raise the temperature to 240°C, slowly evacuate and precondense for 0.5h, and then control the vacuum degree below 200Pa to react for 3h to obtain dark yellow poly-2,5- Ethylene furandicarboxylate (PEF polyester), intrinsic viscosity 0.65dL / g, glass transition temperature 87.0°C, melting point 217.4°C, crystal melting enthalpy ΔH m It is 1.2J / g, the extruded strip and film are dark yellow, the photo of the sample is as follows figure 1 shown. The tensile strength of the spline is 72.1MPa, the tensile modulus is 2.5GPa, and the elongation at break is 3.6%.

Embodiment 2

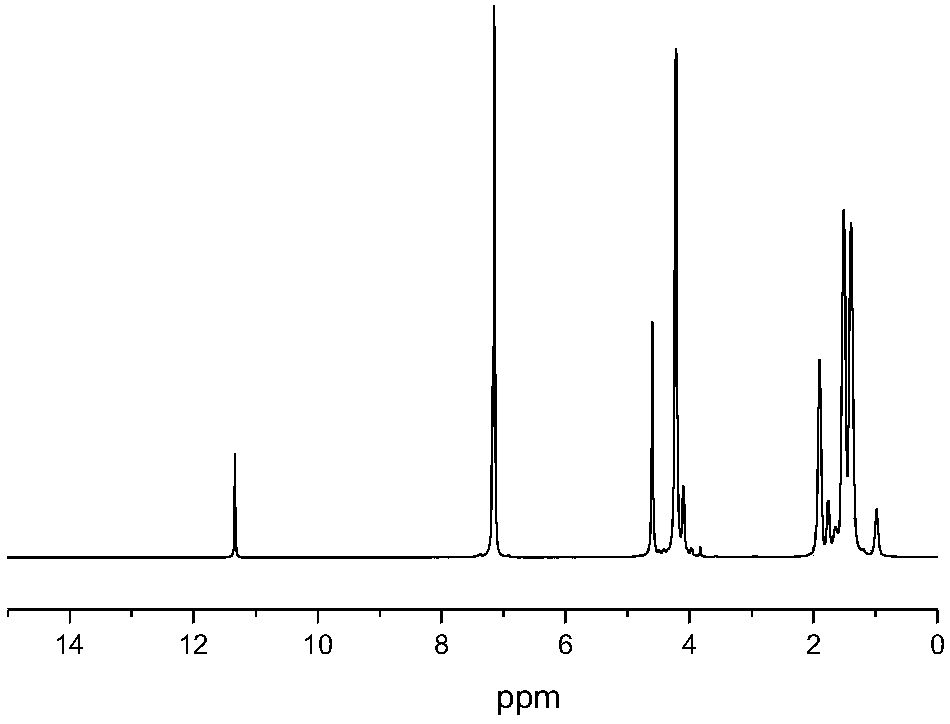

[0071] Mix 0.25mol of 2,5-furandicarboxylic acid, a mixture of 0.02mol of trans-1,4-cyclohexanedimethanol and 0.18mol of cis-1,4-cyclohexanedimethanol, and 0.20mol of ethylene dimethanol Alcohol and 0.0004mol of anhydrous zinc acetate were added to a 500mL reactor, vacuumed and replaced with nitrogen three times, stirring was started, and the temperature was gradually raised to 180°C for 4 hours of reaction. Add antimony trioxide, triphenyl phosphate and antioxidant 1010 into the system, raise the temperature to 240°C, slowly evacuate and precondense for 0.5h, and then control the vacuum degree below 200Pa to react for 3h to obtain furandicarboxylic acid copolyester. 1 H-NMR such as figure 2 As shown, the intrinsic viscosity is 0.82dL / g, the glass transition temperature is 71.5°C, the melting point is 189.1°C, and the melting enthalpy of crystallization is 4.5J / g. DSC shows image 3 shown. T d,5% The thermal decomposition temperature is 380°C, such as Figure 4 shown. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap