Anti-static fabric

An anti-static and anti-static layer technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of poor durability, difficult to adhere anti-static liquid, and poor washability, and achieve excellent washing resistance, improved anti-static effect, combined with The effect of high fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

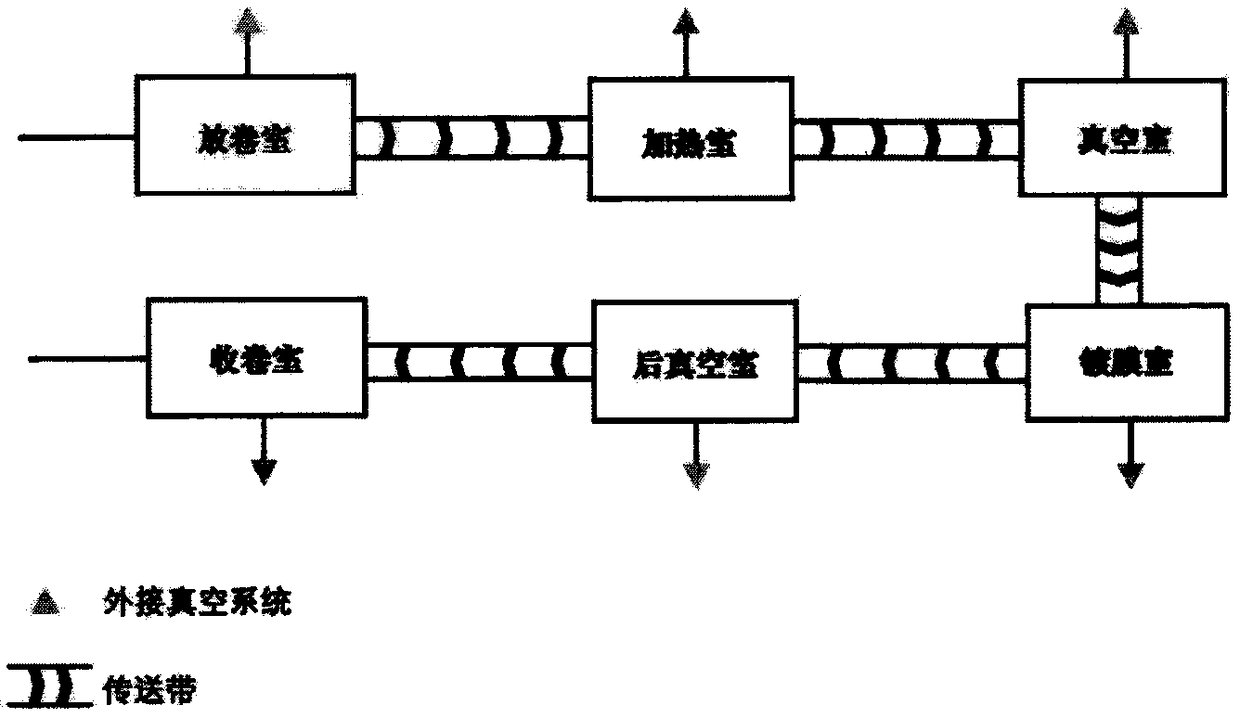

[0028] Such as figure 1 Shown, a kind of preparation method that can realize antistatic fabric, it comprises:

[0029] The base fabric is silk, and the base fabric is pre-treated to remove surface stains;

[0030] The base cloth is rolled into the unwinding chamber to ensure that the vacuum degree of the unwinding chamber is kept at 2.5E -2 Pa interval;

[0031] The base cloth enters the heating chamber, so that the temperature of the base cloth rises to 38°C, and the vacuum degree of the heating chamber is kept at 2.5E -2 Pa interval;

[0032] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 6E -3 Pa interval;

[0033] When the vacuum degree of the coating chamber reaches 1E -3 When the Pa is above, the base fabric enters the coating chamber, the targets are Ti and Cu, and the sputtering power is 3000W and 1500W respectively, and the film is sputtered on the surface of the silk;

[0034] The base cloth enters the winding cha...

Embodiment 2

[0038] Such as figure 1 Shown, a kind of preparation method that can realize antistatic fabric, it comprises:

[0039] The base fabric is pongee, and the base fabric is pre-treated to remove surface stains;

[0040] The base cloth is rolled into the unwinding chamber to ensure that the vacuum degree of the unwinding chamber is kept at 5E -3 Pa interval;

[0041] The base cloth enters the heating chamber, the temperature of the base cloth rises to 50°C, and the vacuum degree of the heating chamber is kept at 5E -3 Pa interval;

[0042] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 3E -4 Pa interval.

[0043] When the vacuum degree of the coating chamber reaches 1E -3 When Pa is above, the base fabric enters the coating chamber, and the targets are TiO 2 , Ag, the sputtering power is 2500W, 8200W respectively, sputtering film on the surface of pongee;

[0044] The base cloth enters the winding chamber to ensure that the vac...

Embodiment 3

[0048] Such as figure 1 Shown, a kind of preparation method that can realize antistatic fabric, it comprises:

[0049] The base fabric is pongee, and the base fabric is pre-treated to remove surface stains;

[0050] The base cloth is rolled into the unwinding chamber to ensure that the vacuum degree of the unwinding chamber is kept at 8E -2 Pa interval;

[0051] The base cloth enters the heating chamber, the temperature of the base cloth rises to 60°C, and the vacuum degree of the heating chamber is kept at 8E -2 Pa interval

[0052] The base cloth enters the pre-vacuum chamber, and the vacuum degree in the chamber is kept at 4E -3 Pa interval;

[0053] When the vacuum degree of the coating chamber reaches 1E -3 When Pa is above, the base fabric enters the coating chamber, the target materials are Zn, CuO, TiN respectively, and the power of 7500W, 1500W, 2000W sputters the film layer on the surface of the base fabric.

[0054] The base cloth enters the winding chamber t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap