High-damping direct-acting-type overflow valve

A direct-acting overflow valve and high damping technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as noise, reduce the service life of working components, and vibration of the valve core, and achieve reduction Small overall volume, reduced required stiffness, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

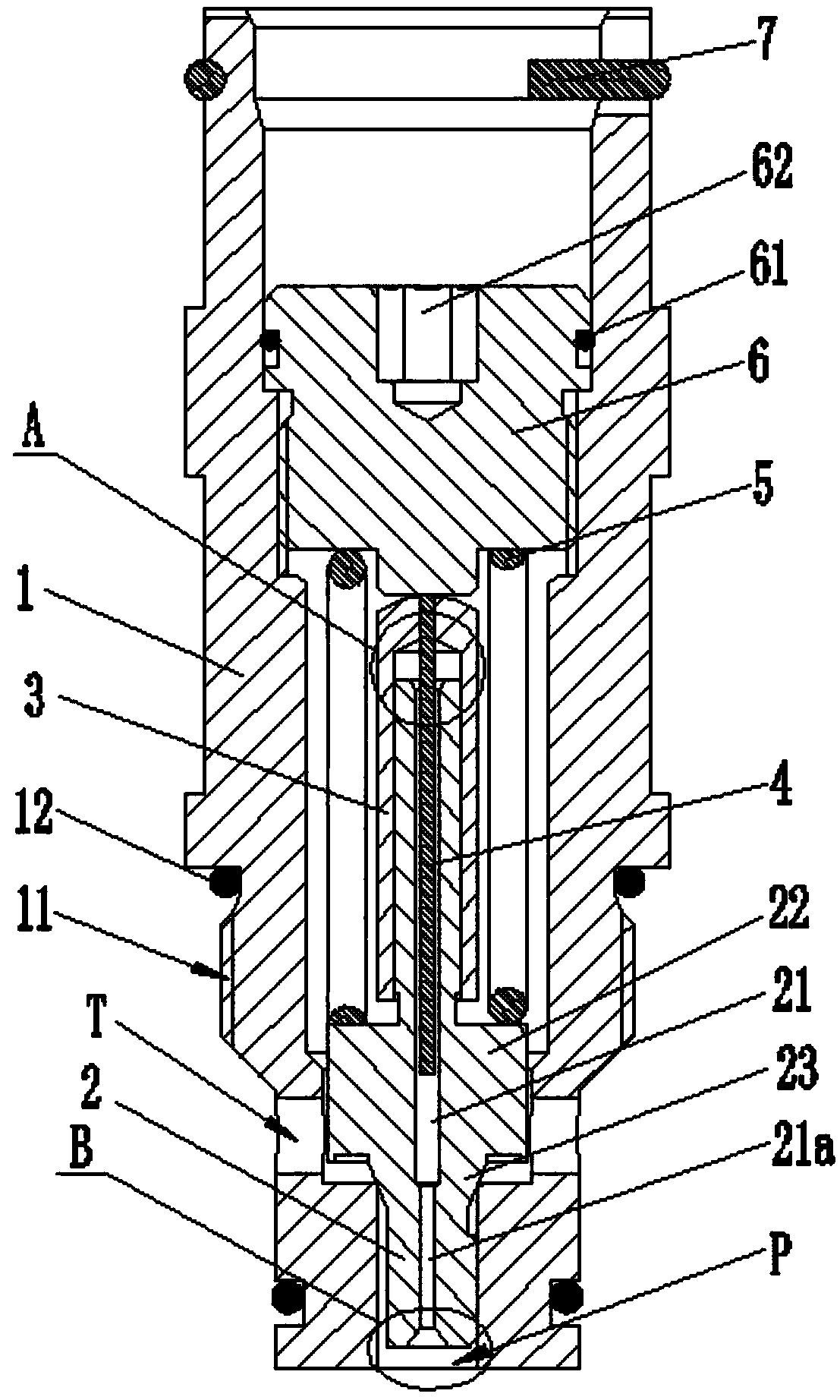

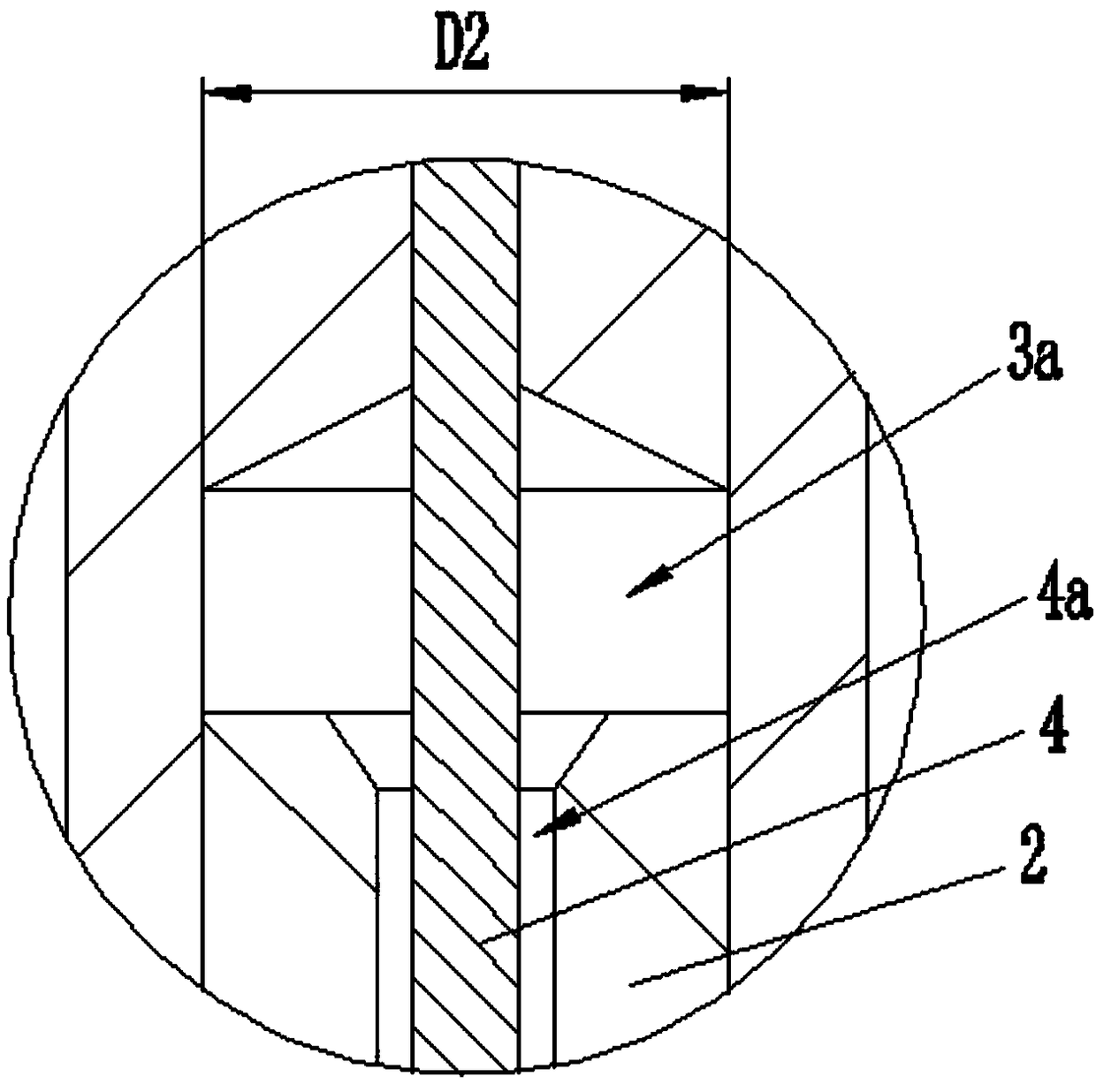

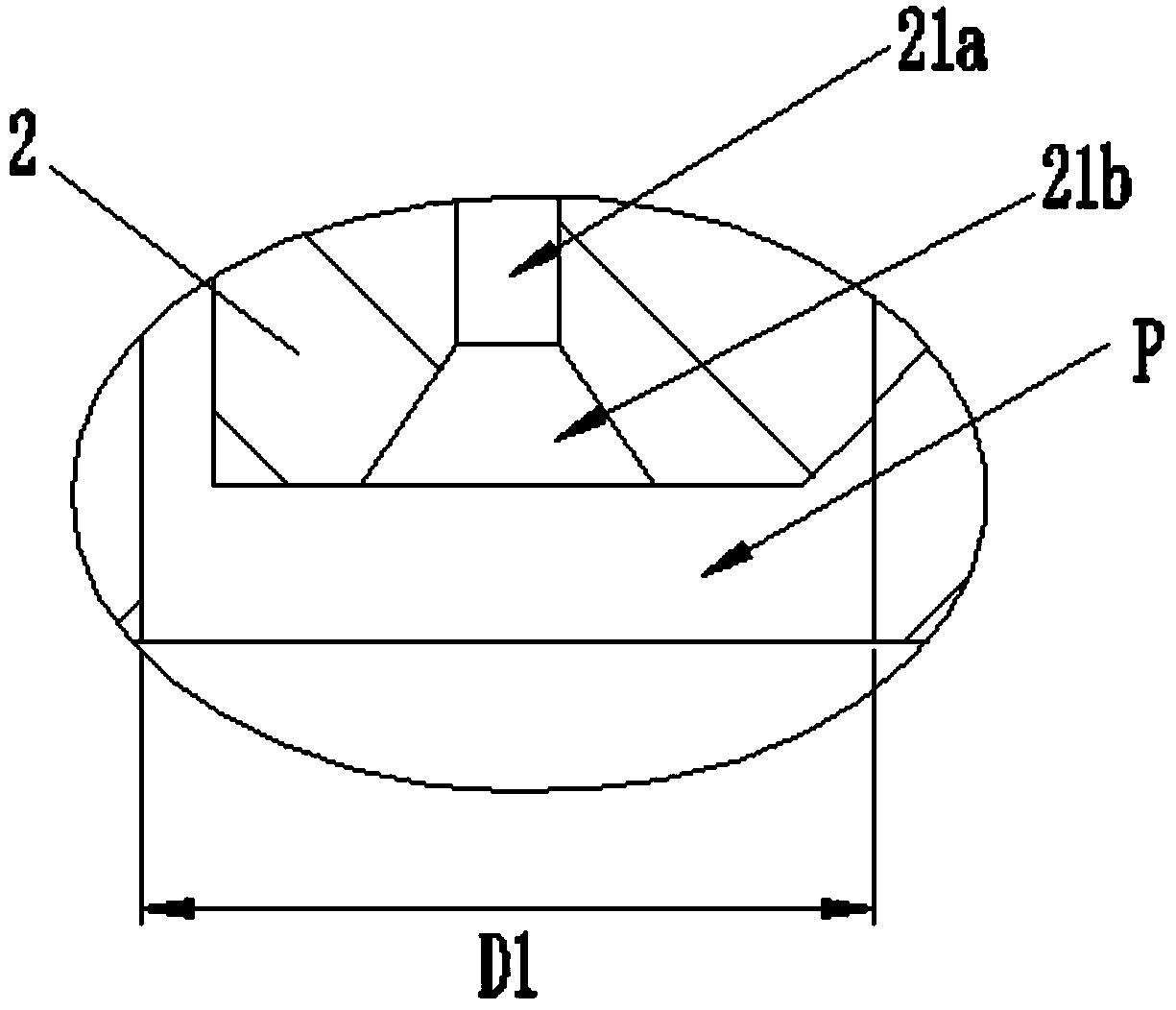

[0022] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0023] The reference signs are: P port, T port, valve body 1, external thread 11, valve body sealing ring 12, valve core 2, flow hole 21, reduced diameter section 21a, tapered hole 21b, convex body 22, Tapered part 23, damping sleeve 3, damping chamber 3a, damping plunger 4, damping gap 4a, spring 5, pressure regulating bolt 6, bolt sealing ring 61, inner hexagonal hole 62, limit retaining ring 7.

[0024] Such as Figure 1 to Figure 3 as shown,

[0025] A high-damping direct-acting overflow valve includes a valve body 1, a P port is vertically opened at the lower end of the valve body 1, a T port is opened on the lower side wall of the valve body 1, and a P port is formed between the P port and the T port. There is a valve port, the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com