Microminiature Swiss roll combustor suitable for non-premixed combustion

A premixed combustion and burner technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of not many application examples, insufficient reaction, large heat loss ratio, etc., and achieve a wide range of wall temperature adjustment. range and power output range, the effect of improving energy utilization, improving flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

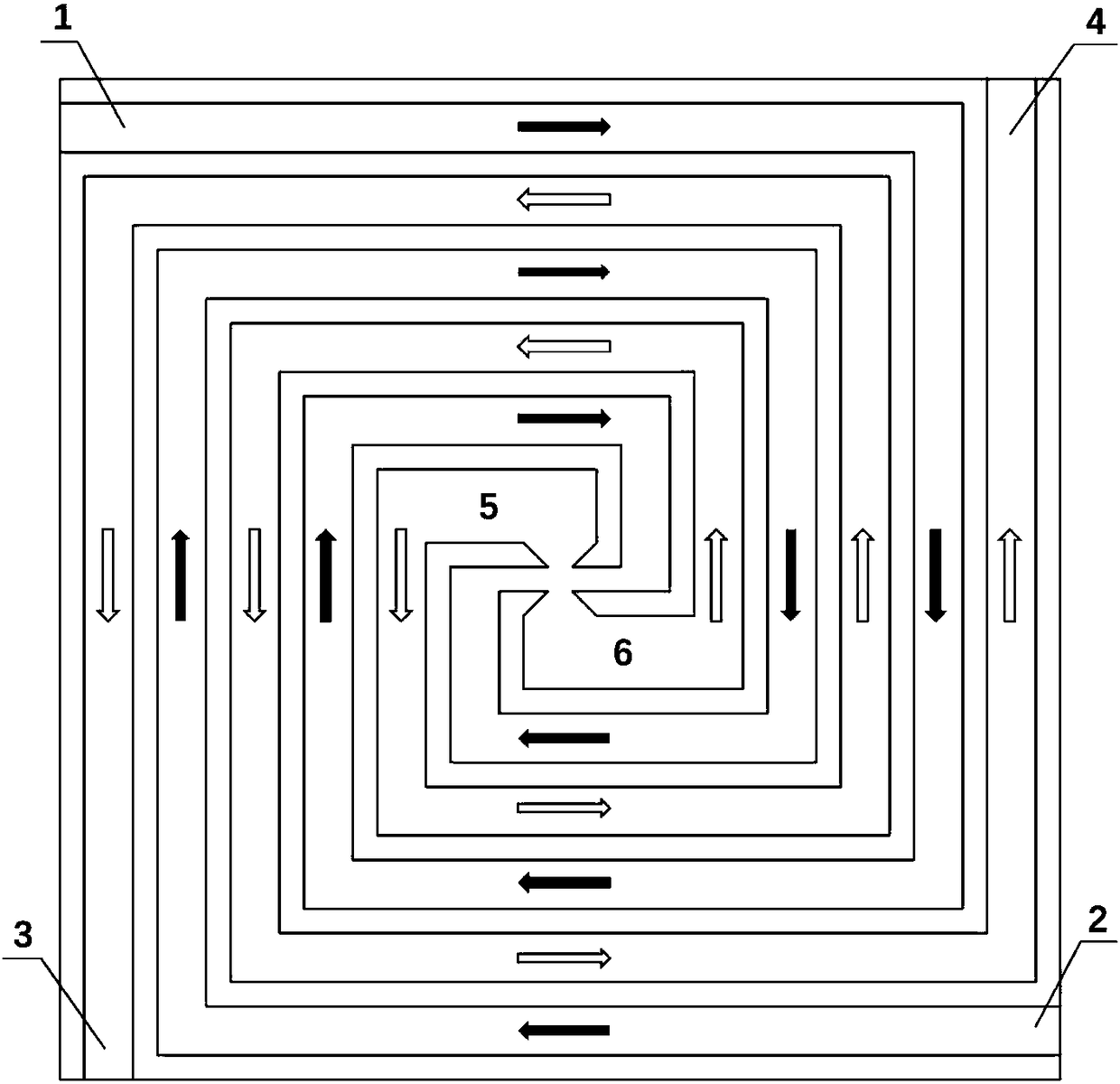

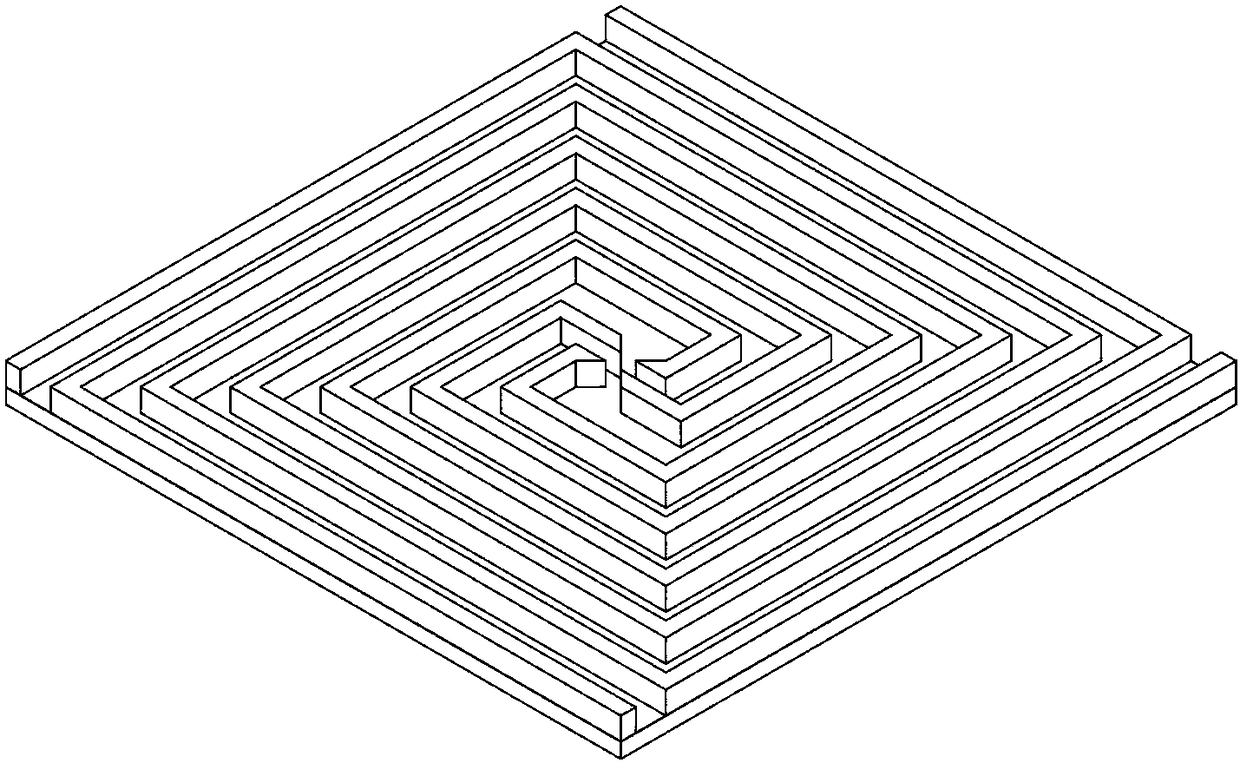

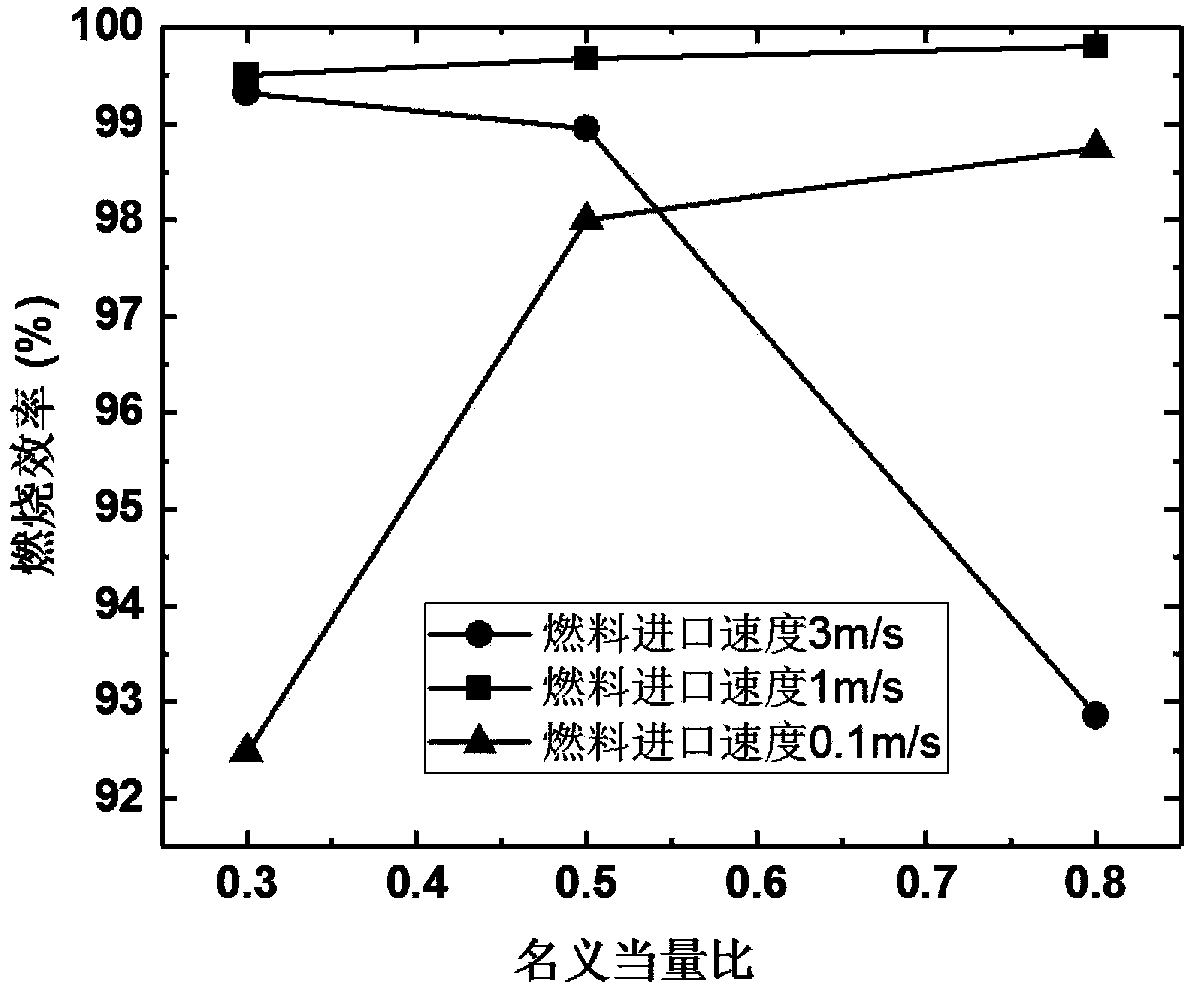

[0030] In this embodiment, hydrogen is used as the fuel, and air is used as the oxidant. The width of the fuel channel and the oxidant channel is 2mm. The structures of the two combustion chambers are the same, and the width is 3mm. And the height of each passage is 3mm, the wall thickness of the partition plate of the combustion chamber and each passage is 1mm, the thickness of the base plate and the upper cover plate is 1mm, and the size of the entire combustion chamber is 41mm×41mm×5mm. The entire burner (that is, the base plate, each channel, each combustion chamber and the upper cover plate) is made of SUS316 material, and its density, specific heat capacity, thermal conductivity and normal emissivity at room temperature are 7980kg / m 3 , 502J / (kg·K), 16.2W / (m 2 K) and 0.65, using the general CFD calculation software Fluent6.3, the combustion characteristics of the burner under different working conditions were numerically simulated, the results are as follows image 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com