Preparation method of novel formaldehyde removing active carbon

A technology of activated carbon and formaldehyde, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex components and various processes, and achieve the effect of improving the ability to remove formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

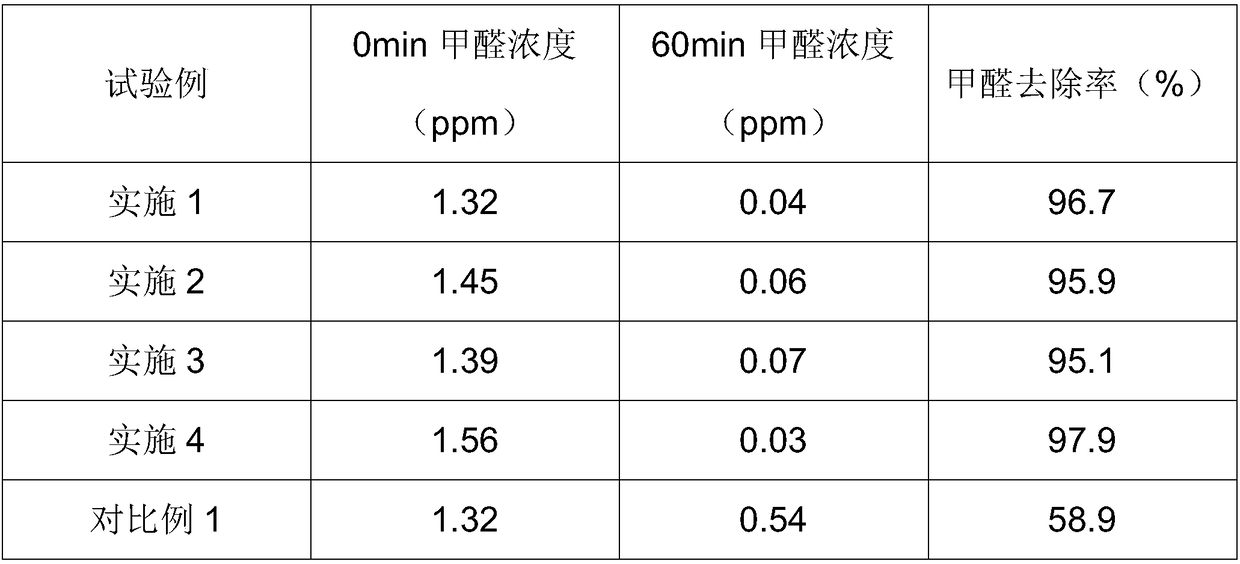

Examples

Embodiment 1

[0017] First, disperse 100.0g of activated carbon, 10.0g of graphene, and 10.0g of butyl titanate into 1000mL of isopropanol to form a mixed solution. The mixed solution was stirred at 90°C for 40min at a stirring rate of 200r / min, and then water The product of the thermal reaction is filtered, and the filtered product is vacuum heat-treated at 600°C for 10 hours to obtain a new formaldehyde-removing activated carbon.

Embodiment 2

[0019] First, disperse 100.0g of activated carbon, 0.1g of graphene, 0.5g of expanded graphite, and 1.0g of polyvinylpyrrolidone into 1000mL of methanol to form a mixed solution, and stir the mixed solution at 30°C for 30min at a stirring rate of 200r / min, then The product of the hydrothermal reaction is filtered, and the filtered product is vacuum heat-treated at 800°C for 8 hours to obtain a new formaldehyde-removing activated carbon.

Embodiment 3

[0021] First, disperse 10.0g of activated carbon with 1.0g of graphene, 0.1g of sodium dodecylsulfonate into 10L of water, methanol, ethanol and isopropanol (v / v / v / v=1:1:1:1) and mix A mixed solution is formed in the solvent, and the mixed solution is stirred at 20°C for 3 hours at a stirring rate of 400r / min, then the product of the hydrothermal reaction is filtered, and the filtered product is vacuum heat-treated at 500°C for 12 hours to obtain a new formaldehyde-removing product Activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com