Chemical good cleaning method

A product and chemical technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of heavy labor, hidden safety hazards for workers, low cleaning quality, etc., to prevent secondary pollution and work efficiency. The effect of improving and shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

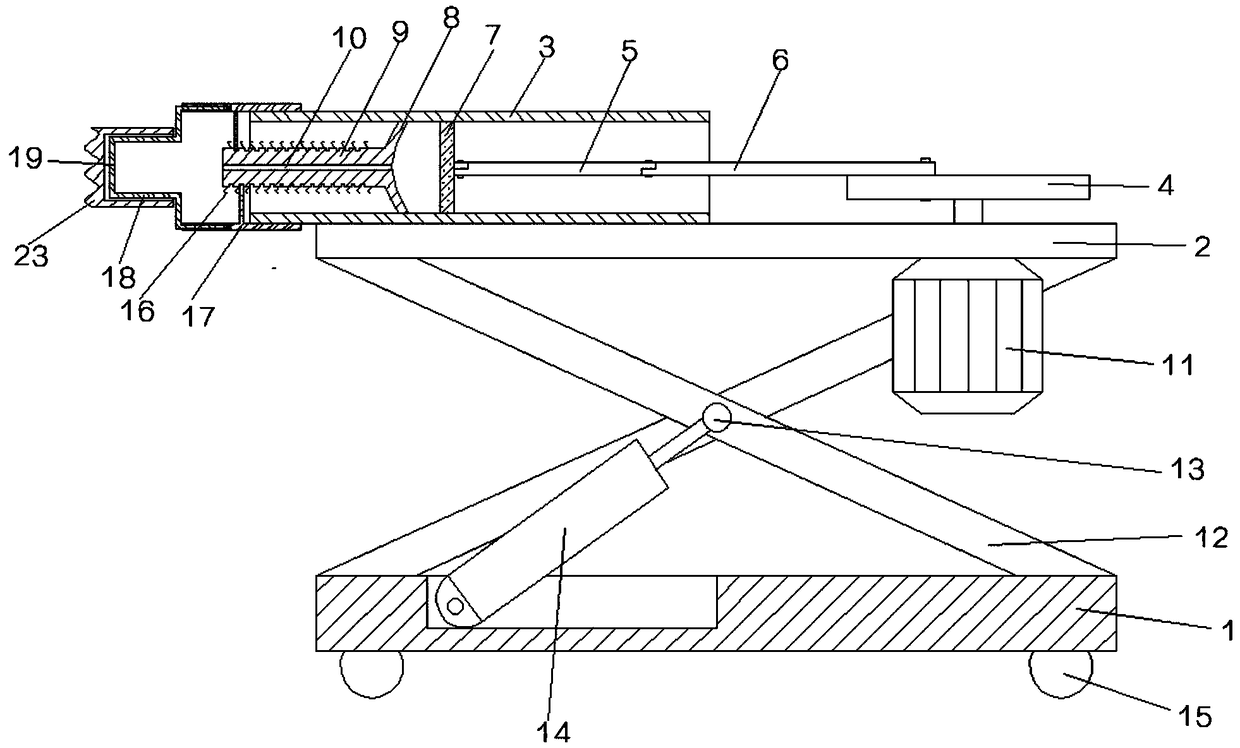

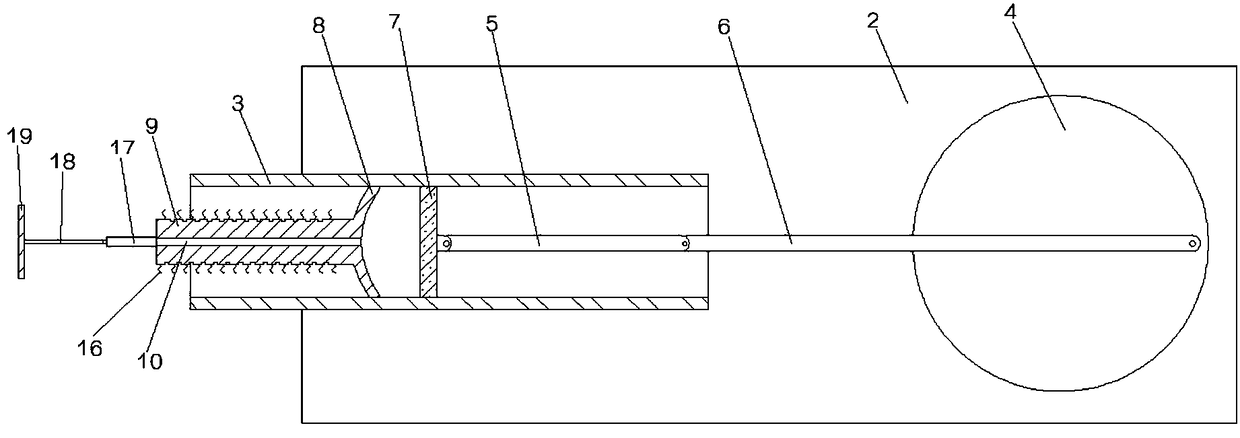

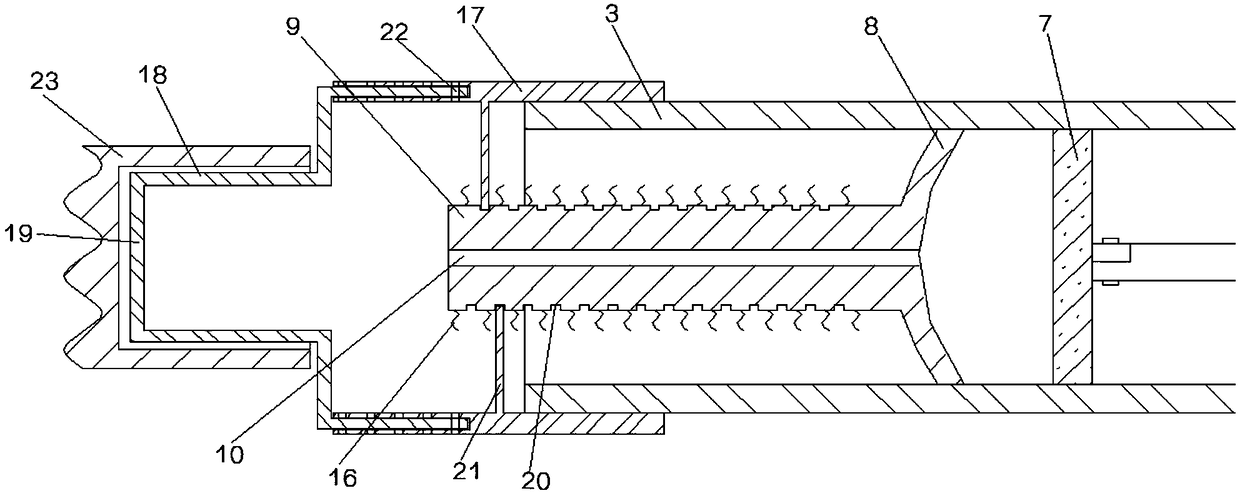

[0025] The reference signs in the drawings of the description include: frame 1, workbench 2, cylinder body 3, driving wheel 4, first connecting rod 5, second connecting rod 6, piston plate 7, film 8, cleaning rod 9, air hole 10. Motor 11, scissor mechanism 12, pin shaft 13, hydraulic cylinder 14, pulley 15, steel wire bristles 16, pillar 17, sliding post 18, retainer 19, spiral groove 20, positioning pin 21, first threaded through hole 22 , Inflow port 23.

[0026] The embodiment is basically as figure 1 , figure 2 and image 3 As shown: the cleaning device includes a frame 1, the frame 1 is rectangular, four pulleys 15 are installed on the lower end of the frame 1, the positions of the pulleys 15 correspond to the corners of the rectangle one by one, and there are two parallel pulleys on the upper end of the frame 1. And with the chute parallel to the edge of the frame 1, two g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com