An Automatically Controlled Constant Pressure Tape Making Method

A constant pressure, central console technology, applied in the preparation of nanocrystalline alloy strips and sub-nanometer alloy strips, and in the field of constant pressure amorphous alloy strips, to reduce the influence of human factors, improve stability and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

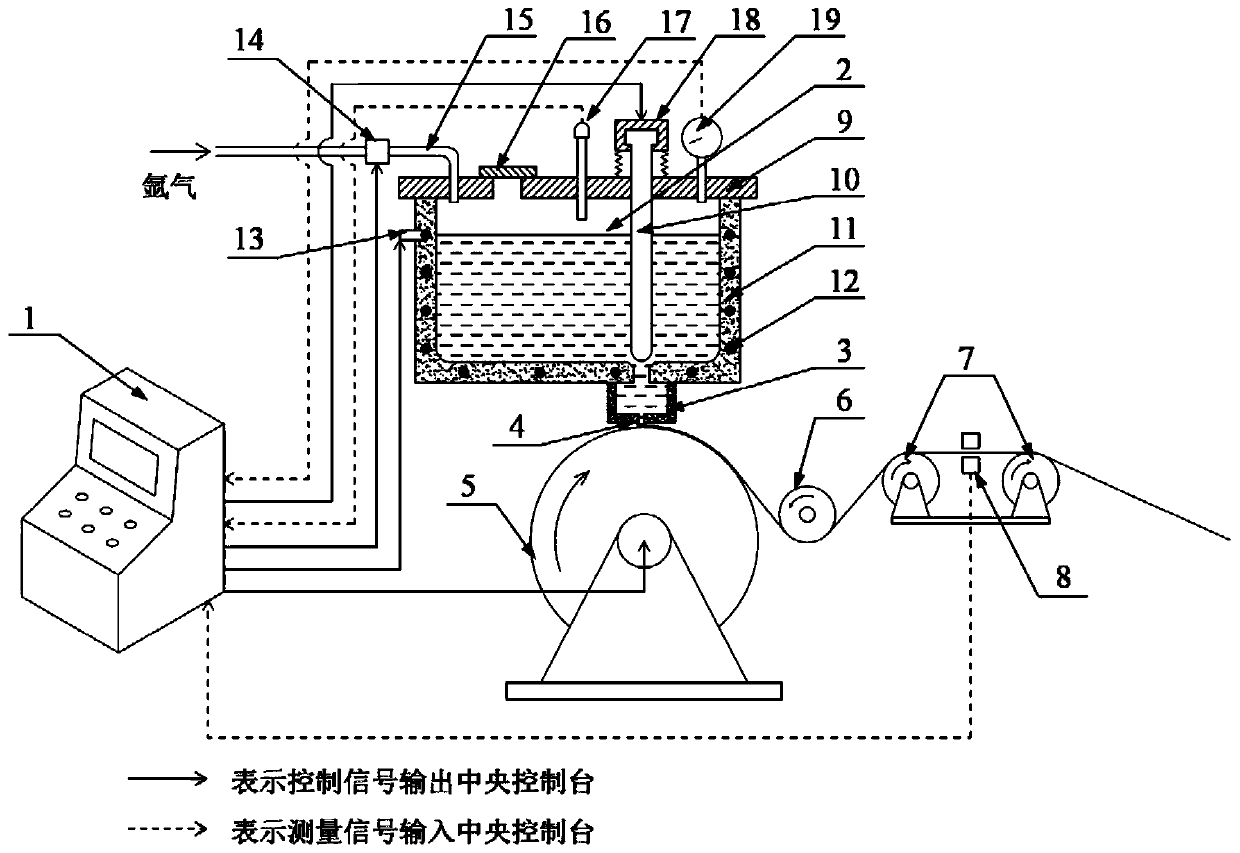

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] figure 1 It is a schematic diagram of a specific embodiment of the present invention. The belt making device is composed of a central console 1, a nozzle bag 2, a nozzle cup 3, a nozzle 4, a cooling roller 5, a pressure roller 6, a support roller 7, an online thickness gauge 8, etc. The relative positional relationship between each component is as follows figure 1 shown. For brevity and clarity, the steel frame and action mechanism supporting the nozzle package 2, pressure roller 6, support roller 7, online thickness gauge 8 and other components, as well as the subsequent strip online coiling mechanism are not drawn in the figure.

[0028] The nozzle package 2 is composed of a package cover 9, a stopper rod 10, a nozzle package lower package 11, a heating silicon carbide rod 12, a silicon carbide rod heater 13, a gas mass flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com