Intelligent steel template grinding system

A steel formwork, intelligent technology, applied in the direction of grinding machine, grinding feed movement, grinding drive device, etc., can solve the problems that concrete residue and iron filings are easy to enter workers' eyes, time-consuming, labor-intensive, personal injury, etc., to facilitate remote monitoring , wide application prospects and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

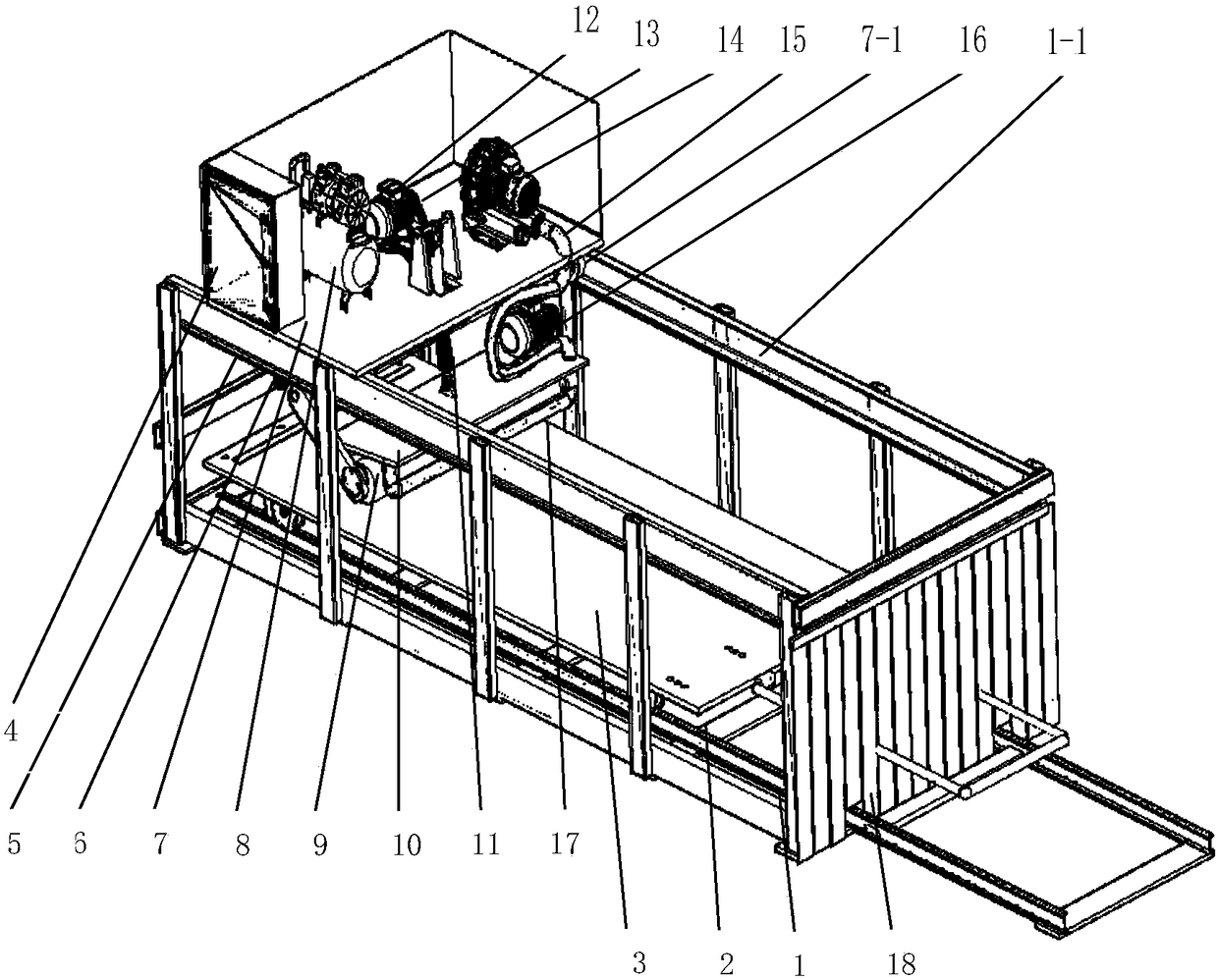

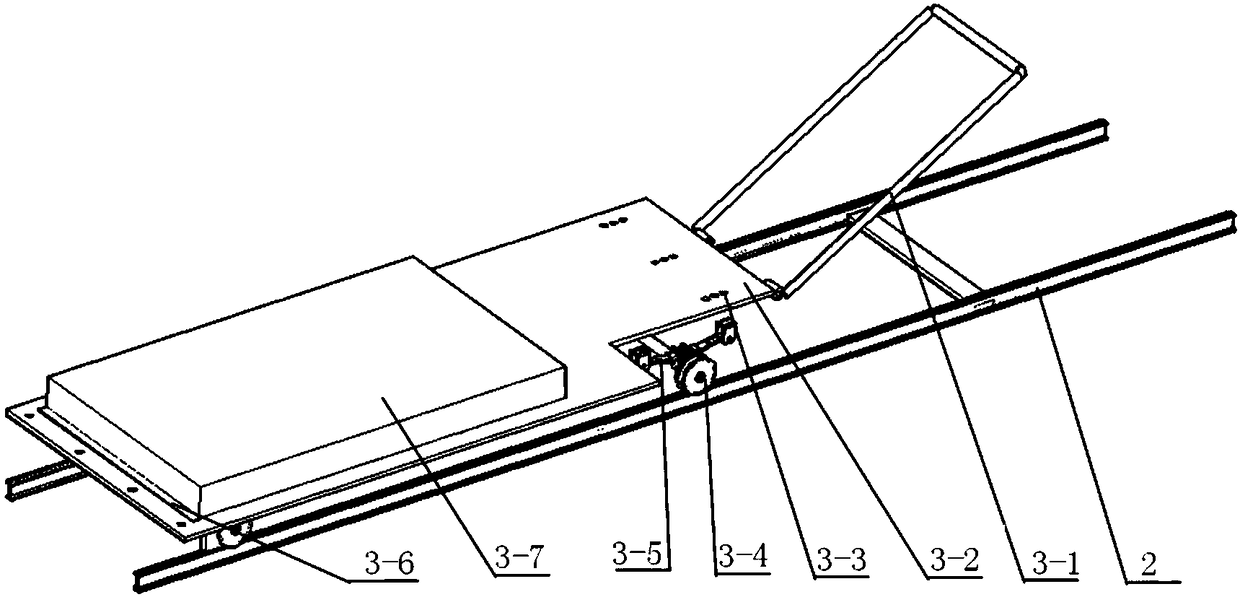

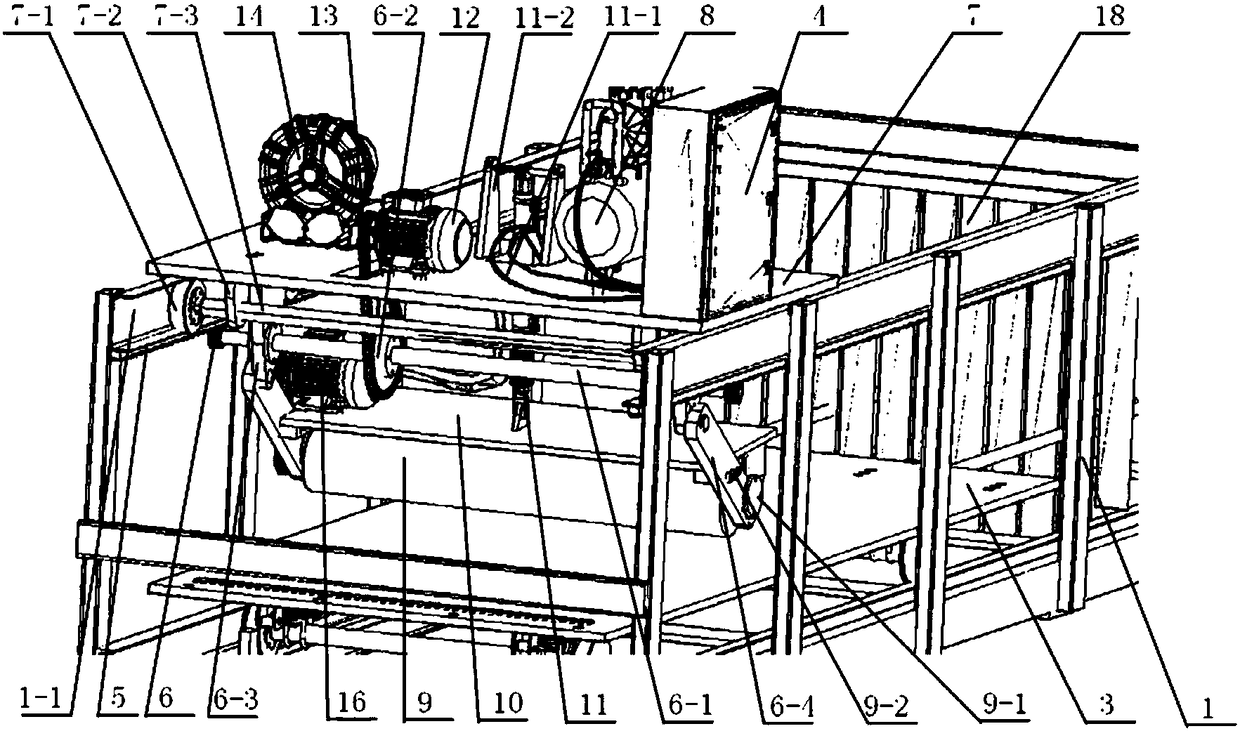

[0086] Embodiment 1: as figure 1 As shown, the Benxi steel formwork automatic grinding machine is mainly composed of frame 1, lower rail 2, carrying vehicle 3, electric control box 4, rack 5, travel gear 6, support plate 7, air compressor 8, grinding mechanism 9, bearing Plate 10, cylinder 11, travel motor 12, transmission chain 13, air blower 14, trachea 15, grinding motor 16, cleaning mechanism 17, ash bar 18 etc. are formed.

[0087] Frame 1 is the supporting body of the whole grinding machine, which is welded into a closed box shape with channel steel, and its length is determined according to the length of the steel formwork to be polished. The principle is to ensure that both the carrying vehicle 3 and the steel formwork can be placed in the frame , the two longitudinal channel steels on the top of the frame 1 are the upper rail 1-1, as the guide groove of the traveling wheel 7-1 below the support plate 7, and the full-length welded rack 5 below the upper rail 1-1, as th...

Embodiment 2

[0092] Embodiment 2: An intelligent steel formwork grinding system, including a monitoring platform (host computer and server, etc.), a grinding machine, on-site monitoring equipment and an intelligent transport vehicle for steel formwork handling;

[0093] The monitoring platform is wirelessly connected to the smartphone. A monitoring app is installed on the smartphone.

[0094] The transport vehicle is provided with a spray gun device, and in the spray gun device, the rotating platform driving motor can drive the rotating platform to rotate through the first transmission mechanism; the rotating platform is provided with a spray gun driving motor 117, and the spray gun driving motor can control the movement of the main spray gun through the second transmission mechanism. elevation angle.

[0095] The first transmission mechanism is a gear transmission mechanism. The gear transmission mechanism includes a first driving gear 122 installed on the rotating shaft of the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com