Active anti-roll bar and control method thereof

A technology of a stabilizer bar and a control method, which is applied in interconnection systems, vehicle springs, vehicle components, etc., can solve the problems of vehicle driving safety, stiffness cannot be adjusted, and roll angle stiffness cannot be adjusted, so as to meet the softness of the suspension Comfort requirements, good suspension soft comfort requirements, the effect of meeting the anti-rolling safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

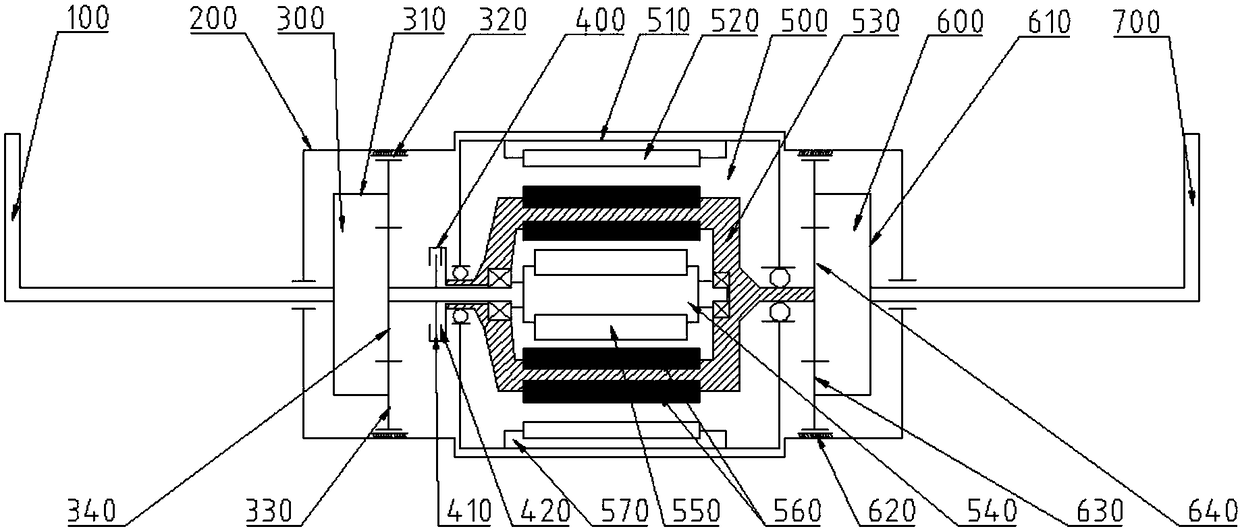

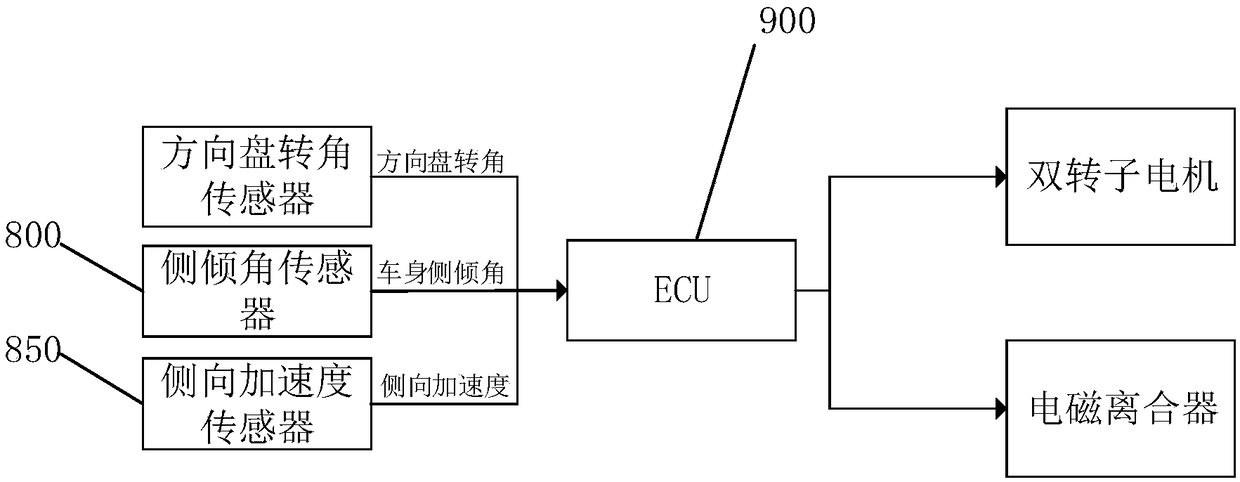

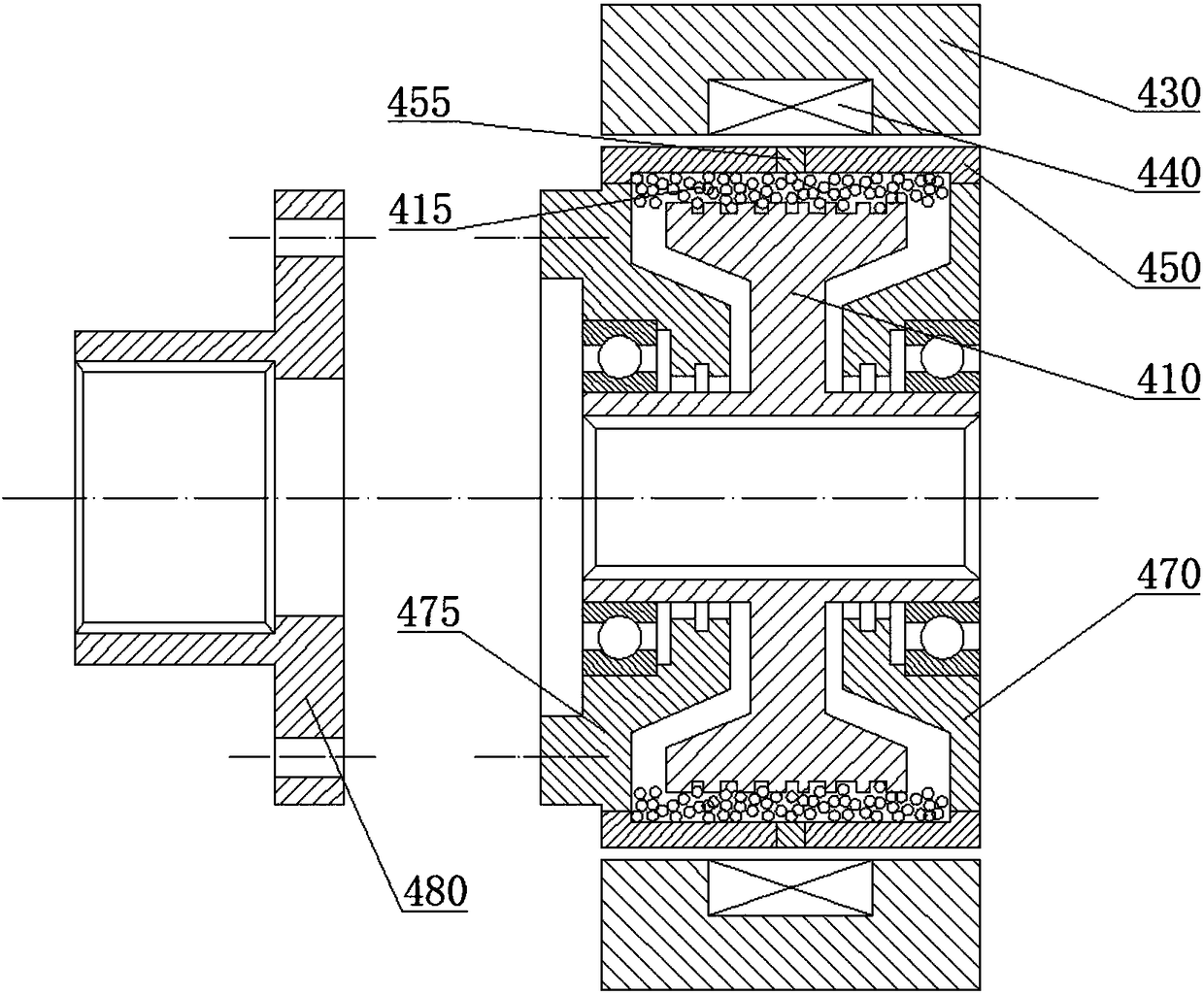

[0058] Such as figure 1 As shown, an active anti-roll bar according to the present invention includes a left half anti-roll bar 100, an actuator casing 200, a left planetary gear mechanism 300, a magnetic powder clutch 400, a flange 480, a double-rotor motor 500, and a right planetary gear Mechanism 600, right anti-roll half rod 700.

[0059] Such as figure 1 As shown, the left anti-roll half rod 100 has an L-shaped structure, and the material is spring steel or other alloy materials. The outer end of the left anti-roll half rod is connected with the lower guide arm of the left suspension through a ball stud, or connected The rod is connected to the lower end of the left shock absorber, the inner end of the left anti-roll half rod is splined to the center hole of the left p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com