A coal sample automatic sampling device

A sampling device and coal sample technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of low coal sampling accuracy, low automation, and low sampling efficiency, and shorten the sampling time , less manual participation, high precision of sample addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

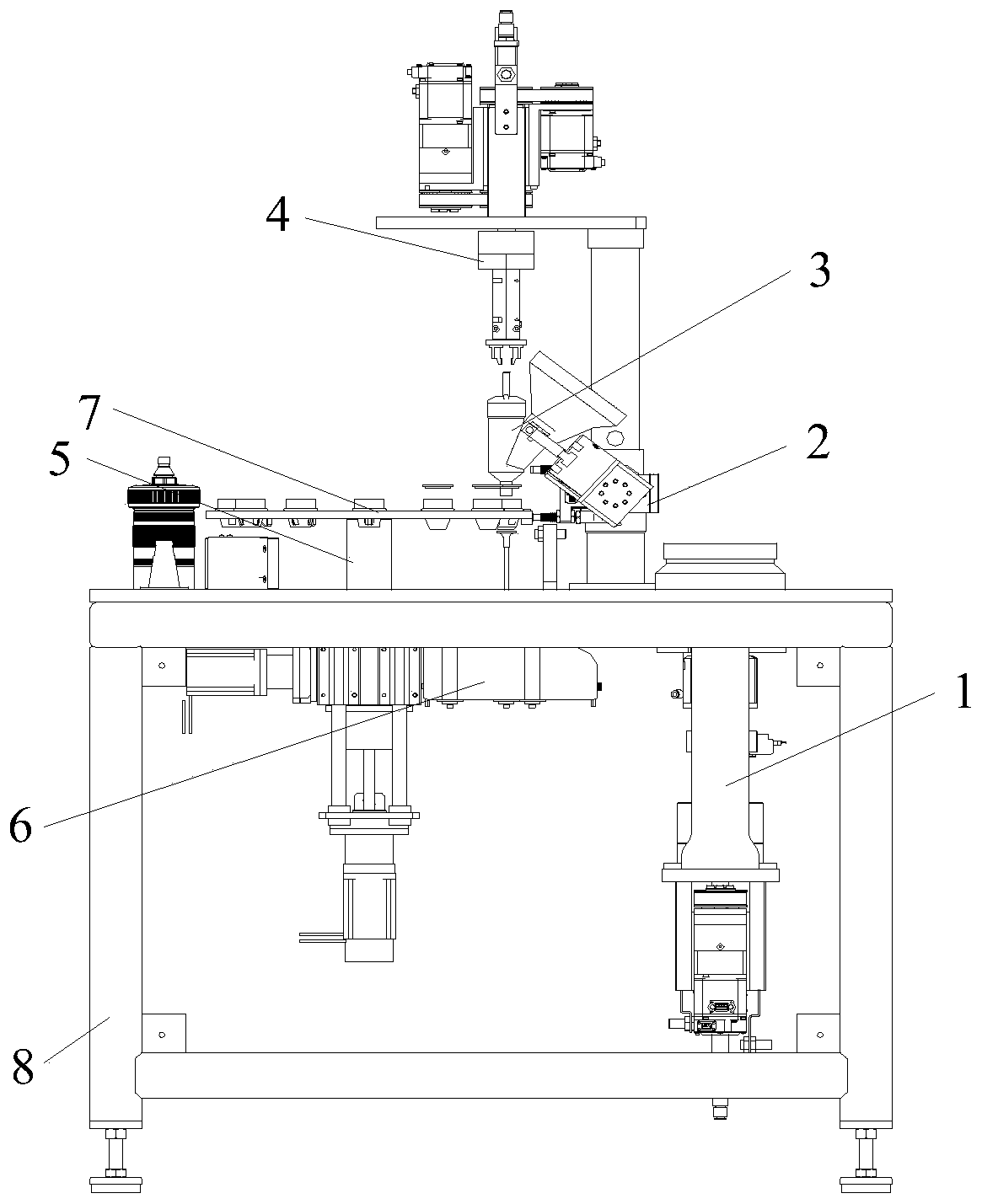

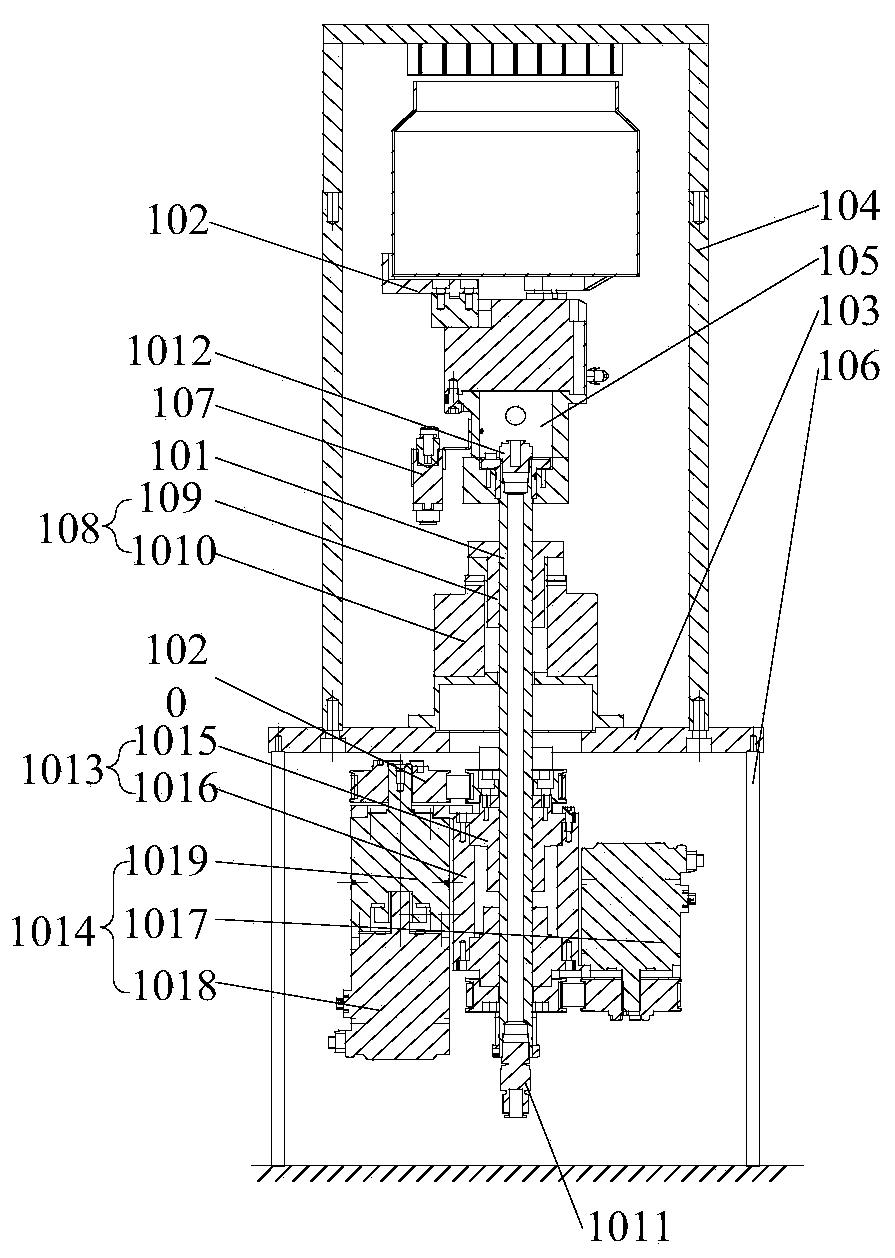

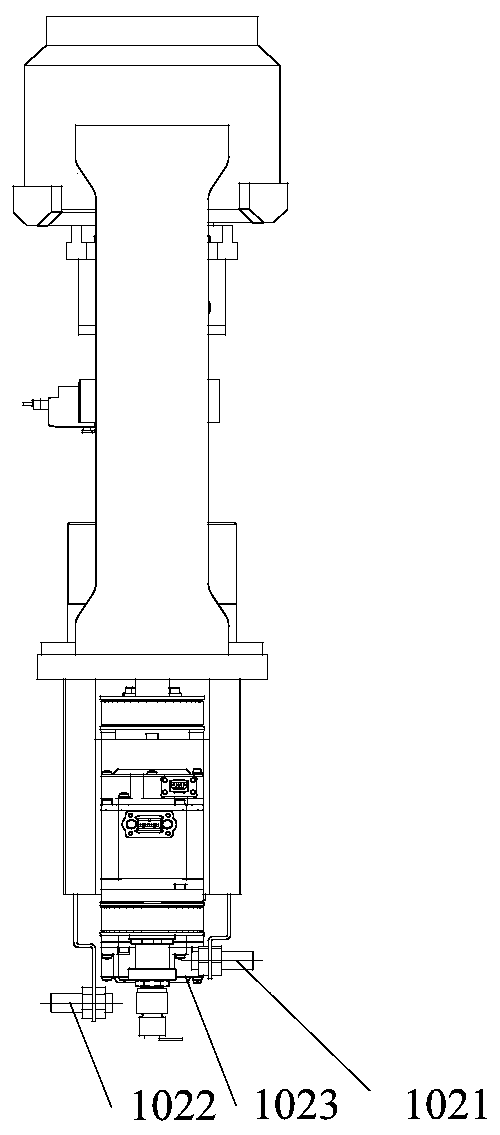

[0043] This embodiment provides a coal sample automatic sampling device, such as Figure 1 to Figure 19As shown, it includes coal sample bottle, cap screwing unit 1, coal sample bottle turning unit 2, sampling head assembly 3, stirring unit 4, turntable lifting unit 5, weighing unit 6, turntable 7 and body 8, and cap screwing unit 1 , coal sample bottle overturning unit 2, turntable lifting unit 5, and weighing unit 6 are all installed on the body 8; cap screwing unit 1 is used to open or close the bottle cap of coal sample bottle; coal sample bottle overturning unit 2 and sampling head Component 3 is fixedly connected, and is used to turn over the sampling head assembly 3; the stirring unit 4 is fixedly connected to the sampling shaft of the sampling head assembly 3, and is used to drive the axial and rotational movement of the sampling shaft of the sampling head assembly 3; The discharge port of the head assembly 3 is located above the crucible station of the turntable 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com