Method using city sludge to produce ceramic floor tiles

A technology for urban sludge and floor tiles, applied in the field of producing ceramic floor tiles, can solve problems such as high equipment operating costs, inability to recycle, air pollution, etc., achieve good resource utilization, short treatment time, and solve the effects of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

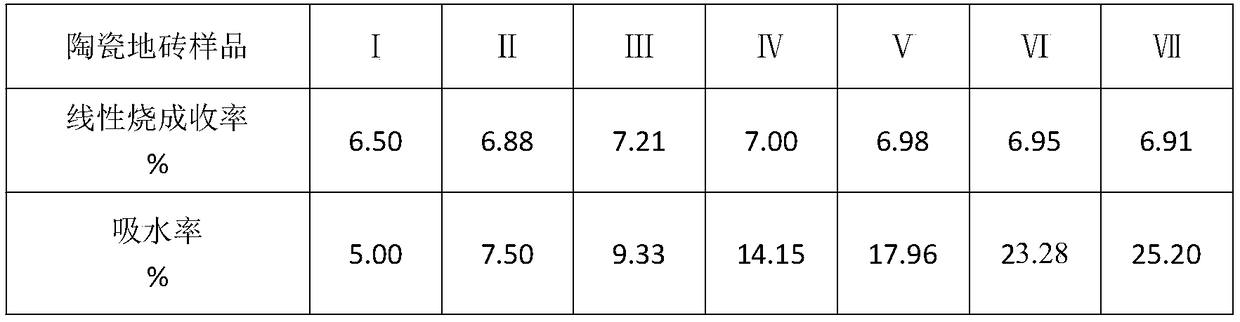

Examples

Embodiment 1

[0027] Step 1, weighing municipal sludge, adding it to a muffle dryer, and drying it at 110°C for 24 hours to obtain dry unroasted sludge;

[0028] Step 2, according to the weight ratio of the dry unroasted sludge and the standard floor tile mixture is 5%, respectively weigh the dry unroasted sludge and the standard floor tile mixture, add them into a horizontal mixer for stirring and mixing, and obtain the mixture I.

[0029] Step 3, the mixture I was left standing for 2h to obtain the mixture II.

[0030] Step 4: According to the weight ratio of water and mixture II is 5%, weigh mixture II and water respectively, put them into an automatic laboratory hydraulic press, and dry press at 30 MPa to obtain rectangular tile sample I.

[0031] In step 5, the rectangular tile sample I was added to a laboratory dryer, and dried at 110° C. for 24 hours to obtain tile sample II.

[0032] In step 6, the tile sample II was placed in a muffle furnace, and fixed at 750° C. for 30 minutes t...

Embodiment 2

[0035] Step 1, weighing municipal sludge, adding it to a muffle dryer, and drying it at 110°C for 24 hours to obtain dry unroasted sludge;

[0036] Step 2, according to the weight ratio of the dry unroasted sludge and the standard floor tile mixture is 10%, respectively weigh the dry unroasted sludge and the standard floor tile mixture, add them into a horizontal mixer for stirring and mixing, and obtain the mixture I.

[0037] Step 3, the mixture I was left standing for 2h to obtain the mixture II.

[0038] Step 4: According to the weight ratio of water and mixture II is 5%, weigh mixture II and water respectively, put them into an automatic laboratory hydraulic press, and dry press at 30 MPa to obtain rectangular tile sample I.

[0039] In step 5, the rectangular tile sample I was added to a laboratory dryer, and dried at 110° C. for 24 hours to obtain tile sample II.

[0040] In step 6, the tile sample II was placed in a muffle furnace, and fixed at 750° C. for 30 minutes ...

Embodiment 3

[0043] Step 1, weighing municipal sludge, adding it to a muffle dryer, and drying it at 110°C for 24 hours to obtain dry unroasted sludge;

[0044] Step 2, according to the weight ratio of the dry unroasted sludge and the standard floor tile mixture is 15%, respectively weigh the dry unroasted sludge and the standard floor tile mixture, add them into a horizontal mixer for stirring and mixing, and obtain the mixture I.

[0045] Step 3, the mixture I was left standing for 2h to obtain the mixture II.

[0046] Step 4: According to the weight ratio of water and mixture II is 5%, weigh mixture II and water respectively, put them into an automatic laboratory hydraulic press, and dry press at 30 MPa to obtain rectangular tile sample I.

[0047] In step 5, the rectangular tile sample I was added to a laboratory dryer, and dried at 110° C. for 24 hours to obtain tile sample II.

[0048] In step 6, the tile sample II was placed in a muffle furnace, and fixed at 750° C. for 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com