Method for processing Xinhui orange spirit

A processing method and technology of spirits, applied in the processing field of Xinhui citrus spirits, can solve the problems of unseen Xinhui citrus spirits processing methods, overflow and volatilization of aroma substances, loss of aroma substances, etc., and achieve rich ester substances , Refreshing and smooth taste, fruity aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

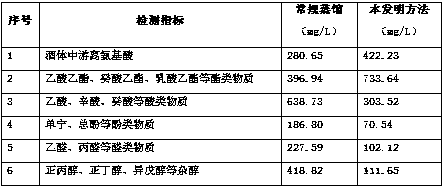

Embodiment 1

[0015] (1) The dry wine obtained by fermenting the whole juice of Xinhuigan is first treated with ultrasonic waves with a frequency of 30kHz and ultraviolet rays with a wavelength of 170nm for 40s at the same time, and then a pulsed electric field with a frequency of 10Hz and an electric field strength of 20kV / cm. 300μs to obtain the fermentation treatment liquid;

[0016] (2) The treatment liquid is subjected to supercritical multi-fluid (CO 2 、H 2 , ethane) to extract the aroma substances, the extraction pressure is 20 MPa, the extraction temperature is 40°C, the fluid flow rate is 30L / h, and the extraction time is 4h; after the extraction is completed, the pressure is quickly reduced to 3 MPa, and the temperature is raised to 54°C. The substances are separated, and the aroma substances are treated with ultrasonic waves with a frequency of 10kHz for 4 minutes, and the temperature is quickly cooled to 2°C, and then kept in a constant temperature airtight storage;

[0017] (...

Embodiment 2

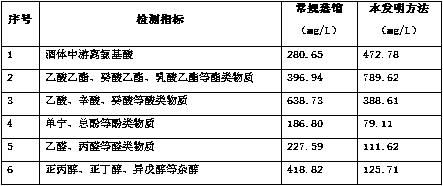

[0024] (1) The dry wine obtained by fermenting the whole juice of Xinhui mandarin oranges is first treated with ultrasonic waves with a frequency of 40kHz and ultraviolet rays with a wavelength of 180nm for 50s at the same time, and then a pulsed electric field with a frequency of 10Hz and an electric field strength of 35kV / cm. 400 μs to obtain the fermentation treatment solution;

[0025] (2) The treatment liquid is subjected to supercritical multi-fluid (CO 2 、H 2 , ethane) to extract aroma substances, the extraction pressure is 30 MPa, the extraction temperature is 42°C, the fluid flow rate is 35L / h, and the extraction time is 5h; after the extraction is completed, the pressure is quickly reduced to 4 MPa, and the temperature is raised to 56°C to release the aroma. The substances are separated, and the aroma substances are treated with ultrasonic waves with a frequency of 15kHz for 5 minutes, and the temperature is quickly cooled to 3°C, and then kept in a constant tempera...

Embodiment 3

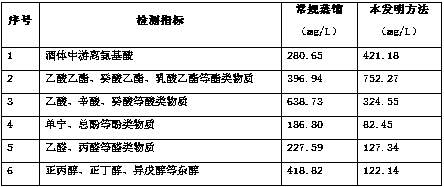

[0033] (1) The dry wine obtained by fermenting the whole juice of Xinhuigan is first treated with ultrasonic waves with a frequency of 50kHz and ultraviolet rays with a wavelength of 220nm for 60s at the same time, and then a pulsed electric field with a frequency of 10Hz and an electric field strength of 55kV / cm. 500μs to obtain the fermentation treatment liquid;

[0034] (2) The treatment liquid is subjected to supercritical multi-fluid (CO 2 、H 2 , ethane) to extract the aroma substances, the extraction pressure is 40 MPa, the extraction temperature is 45°C, the fluid flow rate is 40L / h, and the extraction time is 6h; after the extraction is completed, the pressure is quickly reduced to 5 MPa, and the temperature is raised to 58°C. The substances are separated, and the aroma substances are treated with ultrasonic waves with a frequency of 20kHz for 6 minutes, and the temperature is quickly cooled to 5°C, and then kept in a constant temperature airtight storage;

[0035] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com