Door machine integrated dam

A technology of integrating dam and gate machine, applied in the field of flip gate, can solve the problems of large size of middle pier, affecting flood flow, corrosion and insulation of electric control device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

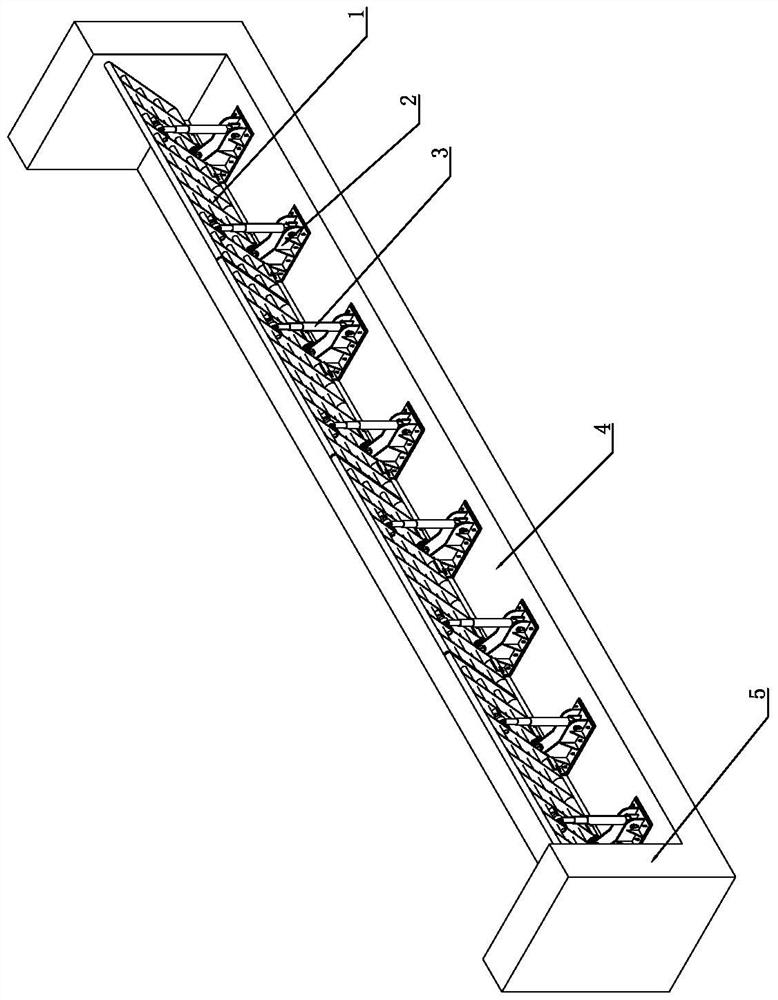

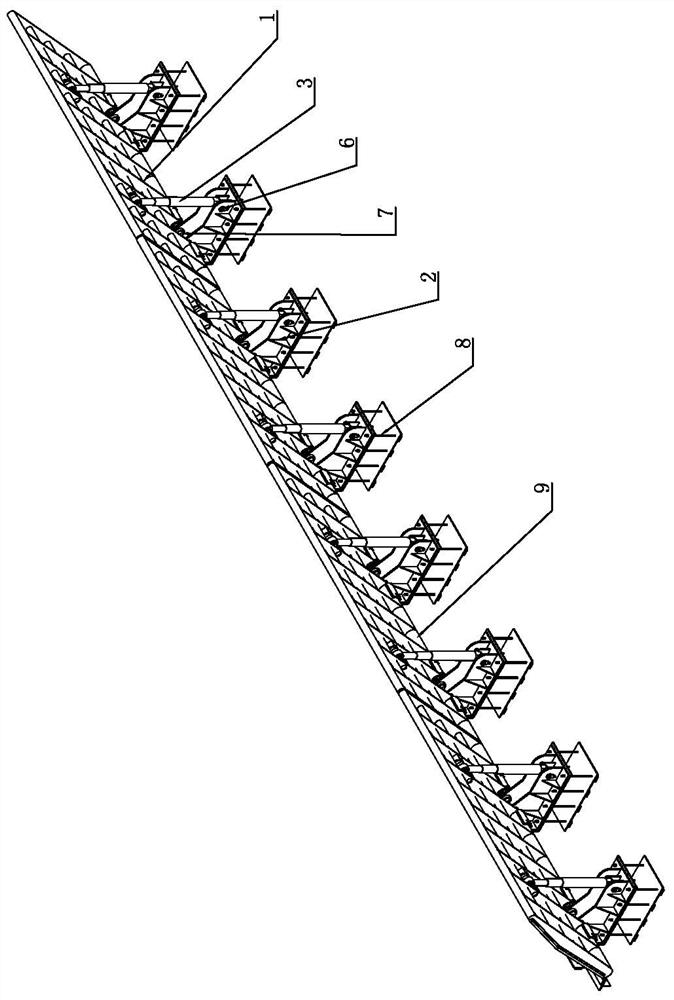

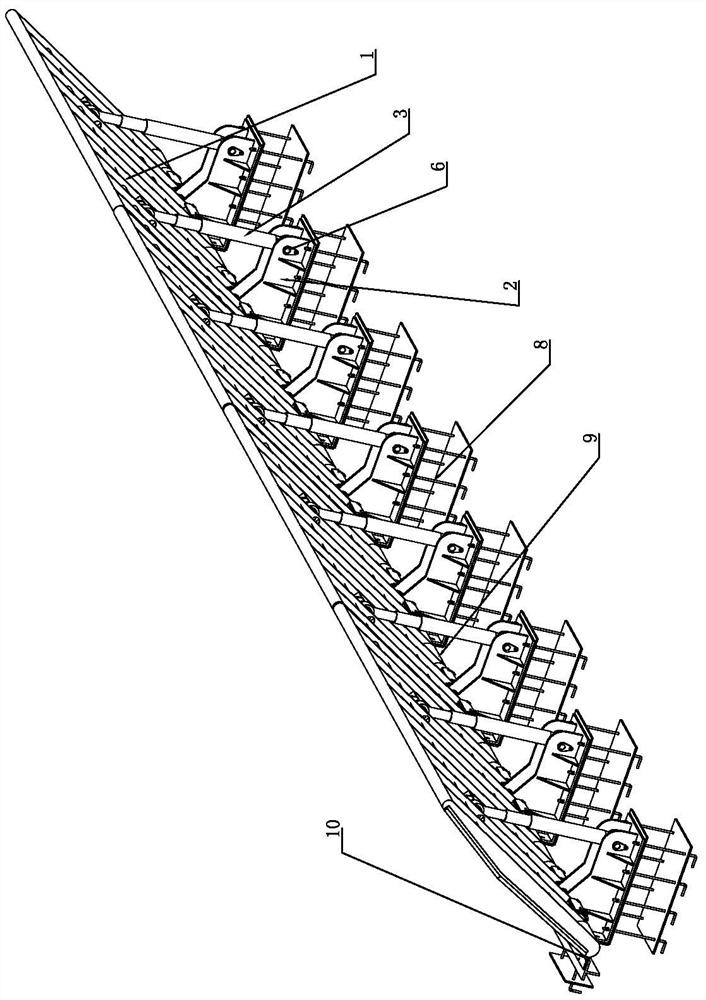

[0024] As shown in the figure, it is a gate machine integrated dam, including a gate body 1 installed between the gate walls 5. The left and right sides of the gate body 1 form a sealing structure with the gate wall 5 by installing side water-stop rubber to prevent side water leakage. A bottom waterproof rubber 10 is installed between the bottom of the door body 1 and the bottom sill 4 to form a sealed structure to prevent water leakage at the bottom. Several hinge seats 2 are fixed on the bottom sill 4; The front pin shaft 7 is hingedly connected, and the backwater side of the door body 1 is provided with a hydraulic cylinder 3. The hydraulic cylinder 3 is a secondary oil cylinder. The rear pin 6 is hingedly connected to the rear end of the hinge seat 2 through the rear. The hinge seat 2 is fixedly installed on the sill embedded part 8 by bolts, the sill 4 is provided with an L-shaped step, and the sill embedded part 8 is embedded on two mutually perpendicular surfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com