Underground comprehensive pipe gallery prefabricated assembling construction method

A technology of prefabricated assembly and construction method, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of low construction efficiency, damage to the pipe gallery structure, large size error, etc., to improve construction efficiency and quality, save money Construction cost and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0026] A prefabricated and assembled construction method for an underground comprehensive pipe gallery, comprising the following steps:

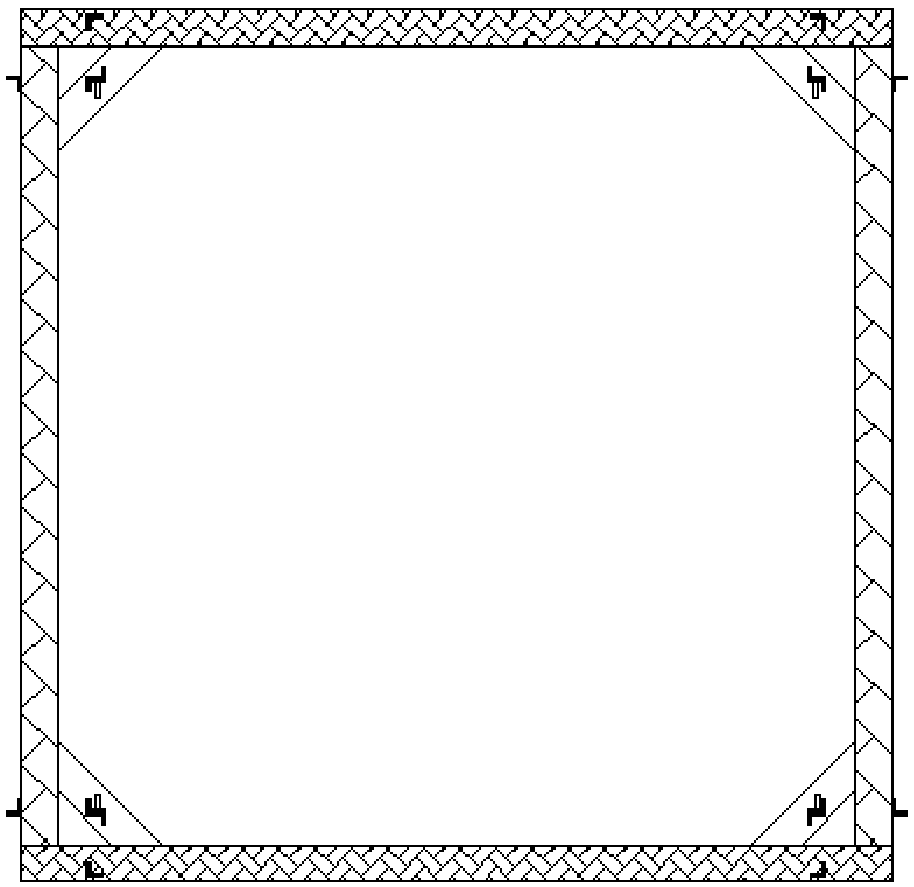

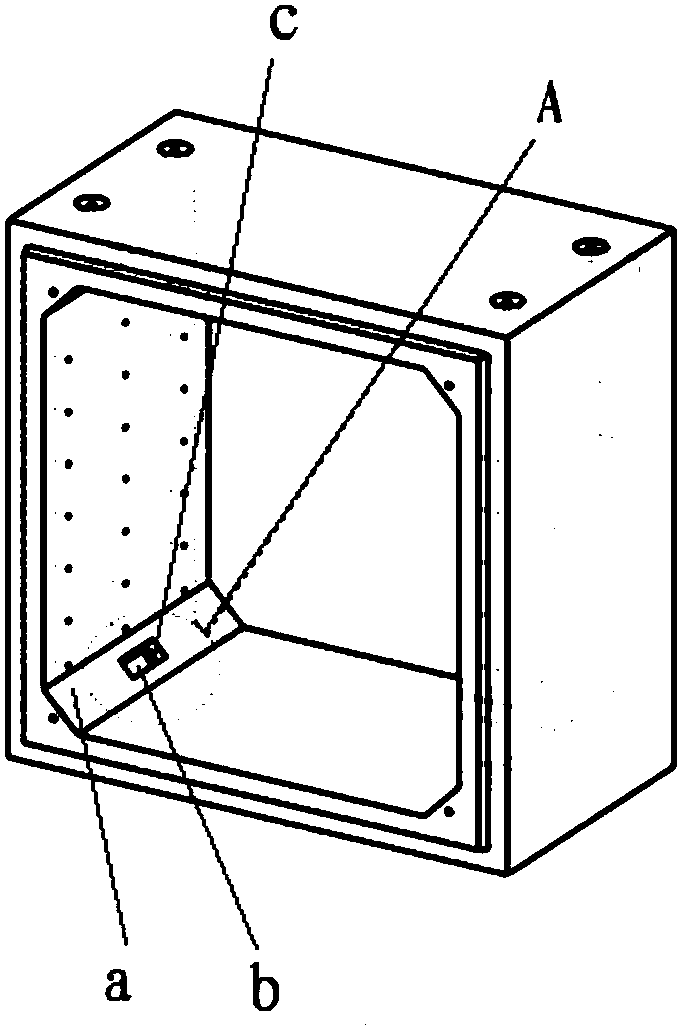

[0027] (1) Make molds and reinforcement cages;

[0028] (2) Concrete pouring and vibration;

[0029] (3) Steam curing and demoulding;

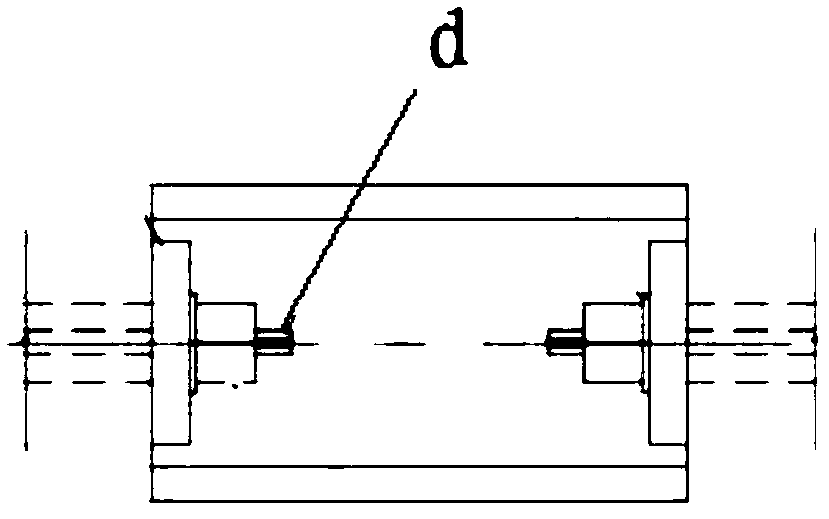

[0030] (4) lifting and transportation;

[0031] (5) Assembly. The above steps are the necessary steps of the prefabricated assembly construction method of the underground comprehensive pipe gallery, and the key of the present invention is:

[0032] Before step (1), carry out BIM modeling, simulate the pre-construction of the entire project, conduct collision checks in various disciplines, optimize construction drawings in a timely manner, realize refined management and dynamic management of project costs, and significantly improve construction efficiency and save construction costs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com