Prefabricated closed balcony and construction method thereof

A construction method and balcony technology, which can be applied to balconies, manufacturing tools, building components, etc., can solve the problems of hidden water seepage at the joints of components, low production efficiency of prefabricated component factories, and low efficiency of on-site construction and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

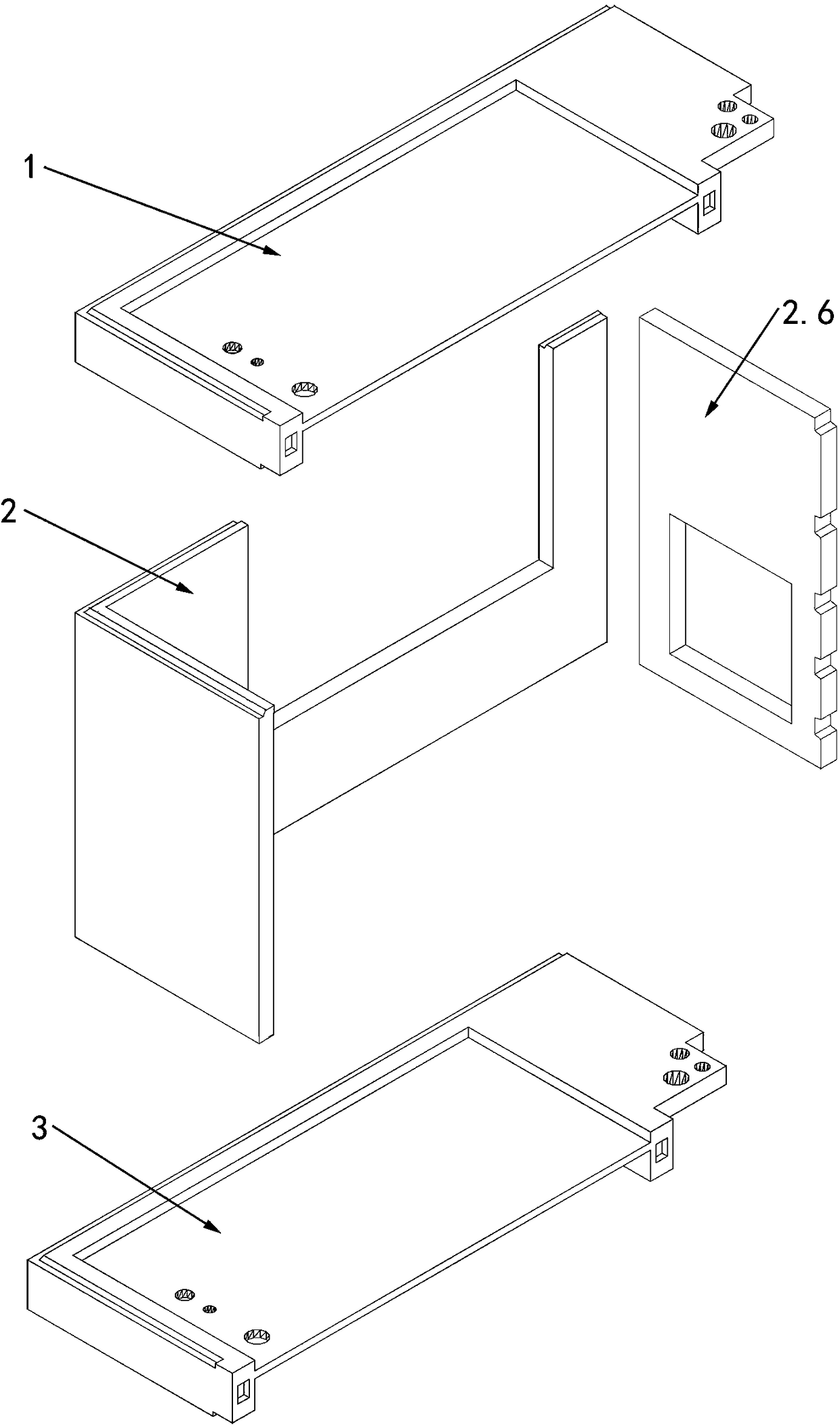

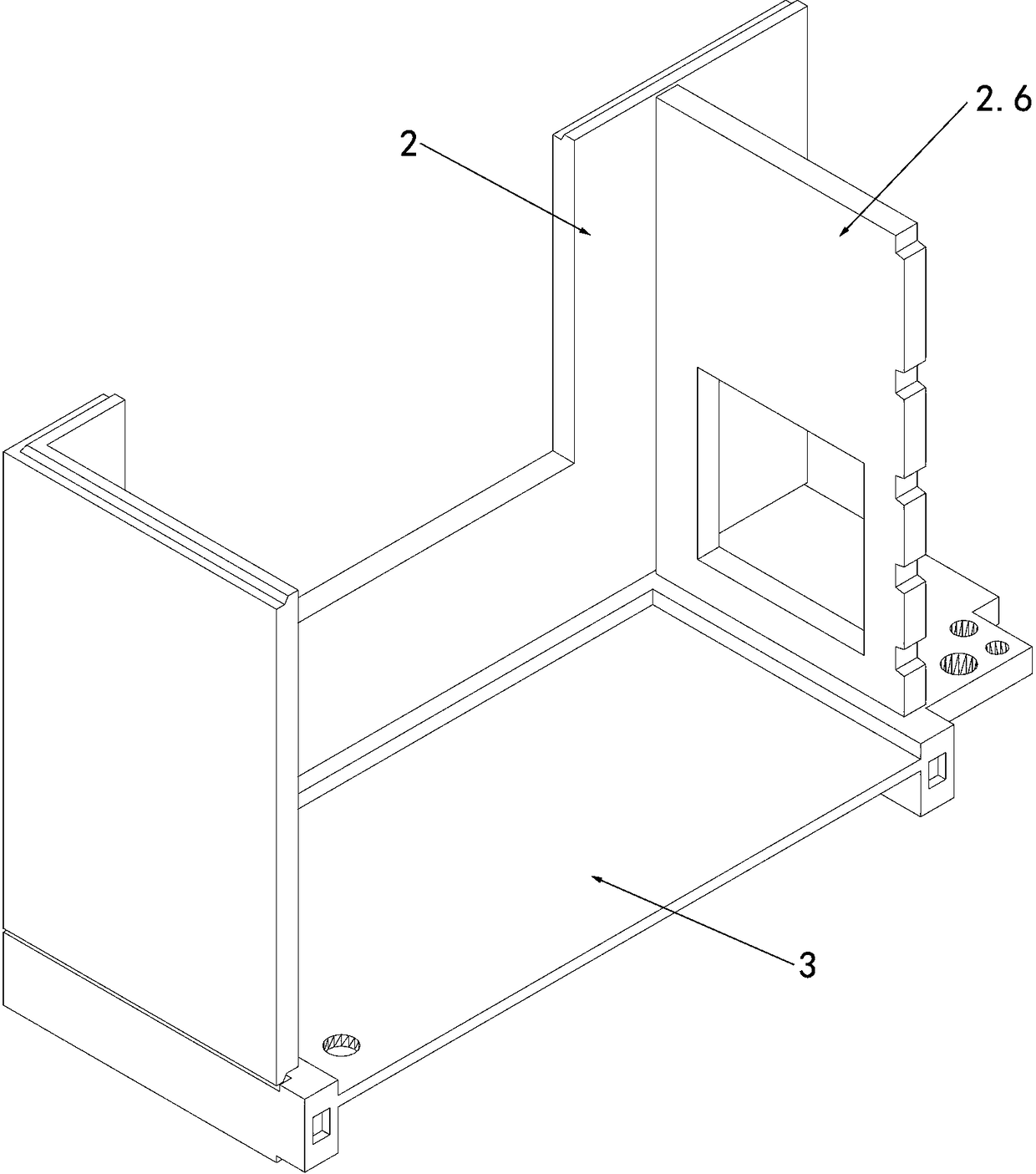

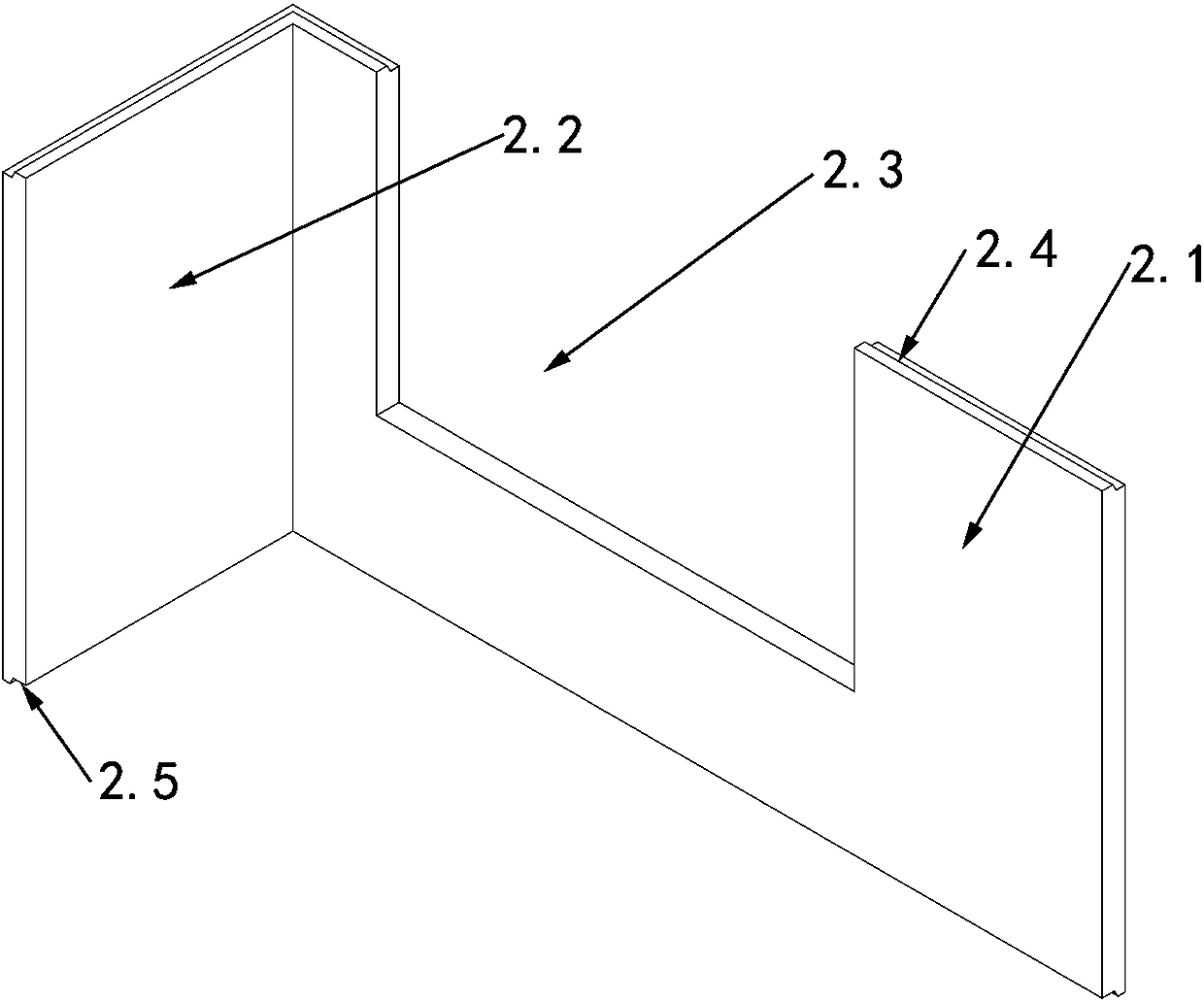

[0076] refer to Figure 1-8 , a prefabricated closed balcony described in this specific embodiment, comprising an upper prefabricated balcony and an air-conditioning integrated laminated beam balcony slab 1, a fully prefabricated balcony partition 2, a lower prefabricated balcony and an air-conditioning integrated laminated beam balcony slab 3. The top connector 4 of the balcony partition and the bottom connector 5 of the balcony partition. The fully prefabricated balcony partition 2 is located on the upper prefabricated balcony and air-conditioning integrated laminated beam balcony slab 1 and the lower prefabricated balcony and air-conditioning integrated composite beam Between the balcony panels 3, the upper part of the fully prefabricated balcony panel 2 is connected to the upper prefabricated balcony and the air-conditioning integrated laminated beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com