Plastic Intake Manifold Assembly for Naturally Aspirated Engines

An intake manifold and naturally aspirated technology, applied to engine components, machines/engines, combustion air/combustion-air treatment, etc., can solve problems such as high power output, difficulty in obtaining, and low intake air volume, and achieve enhanced The effect of low strength, low density and low air intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

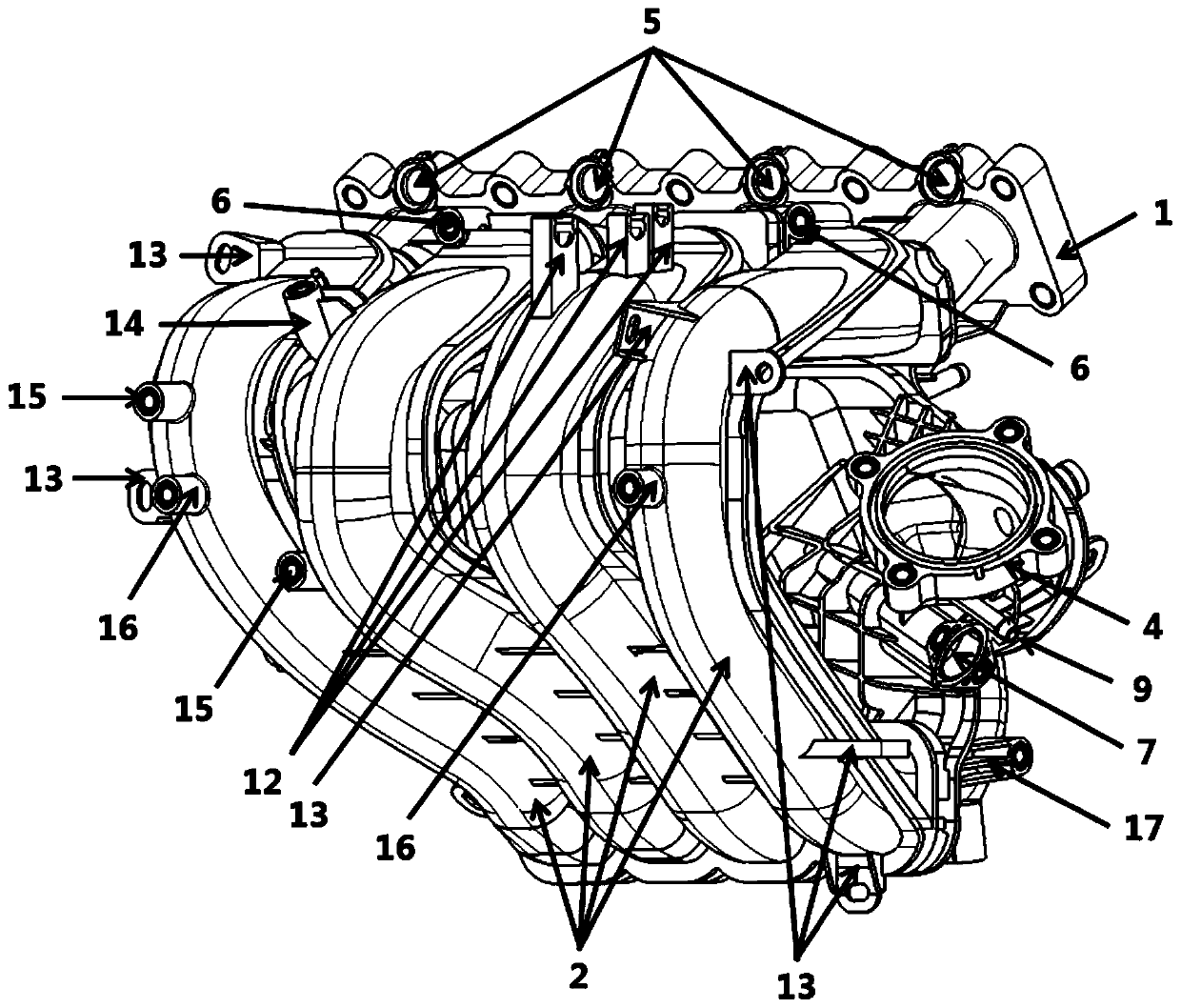

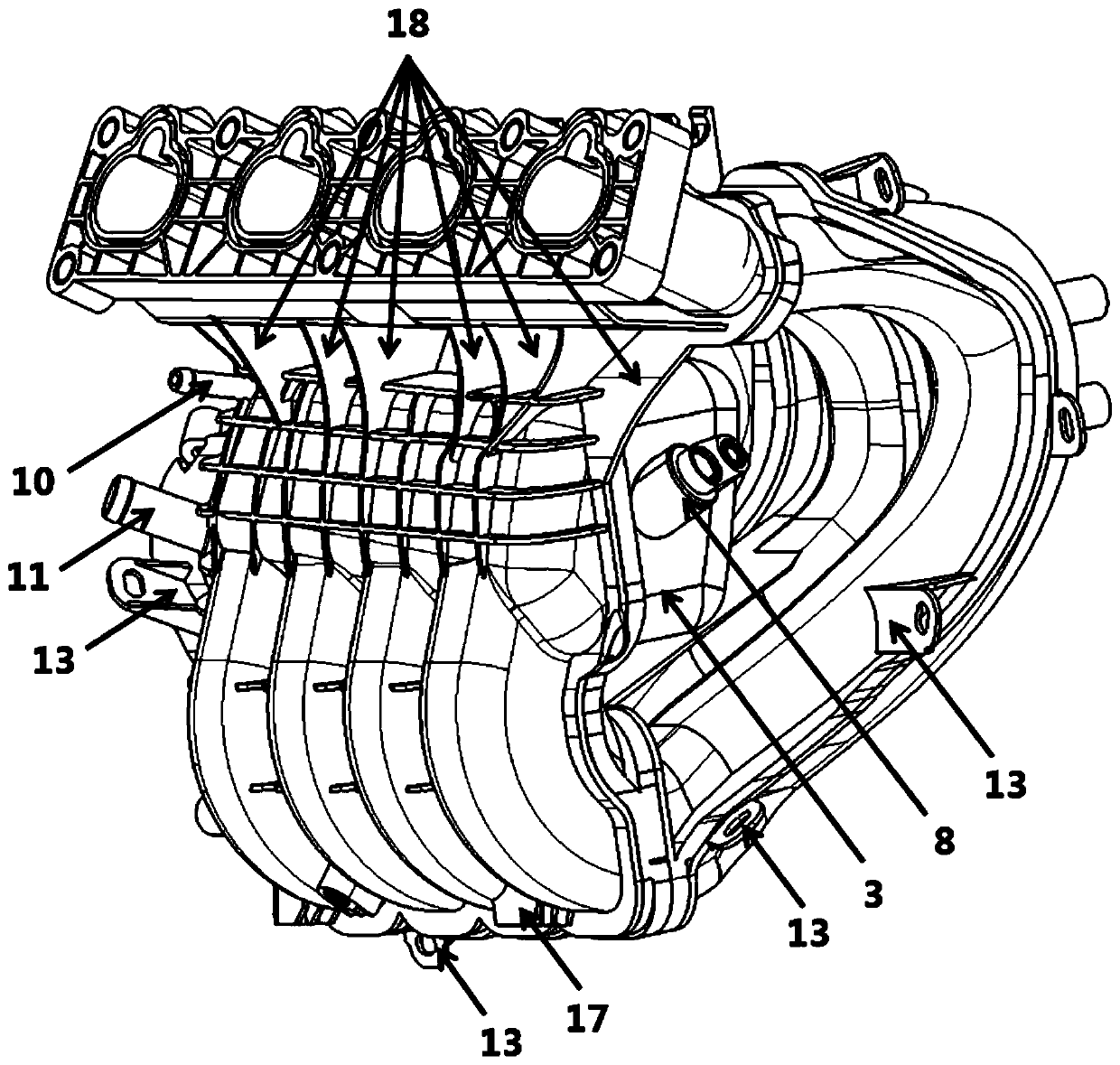

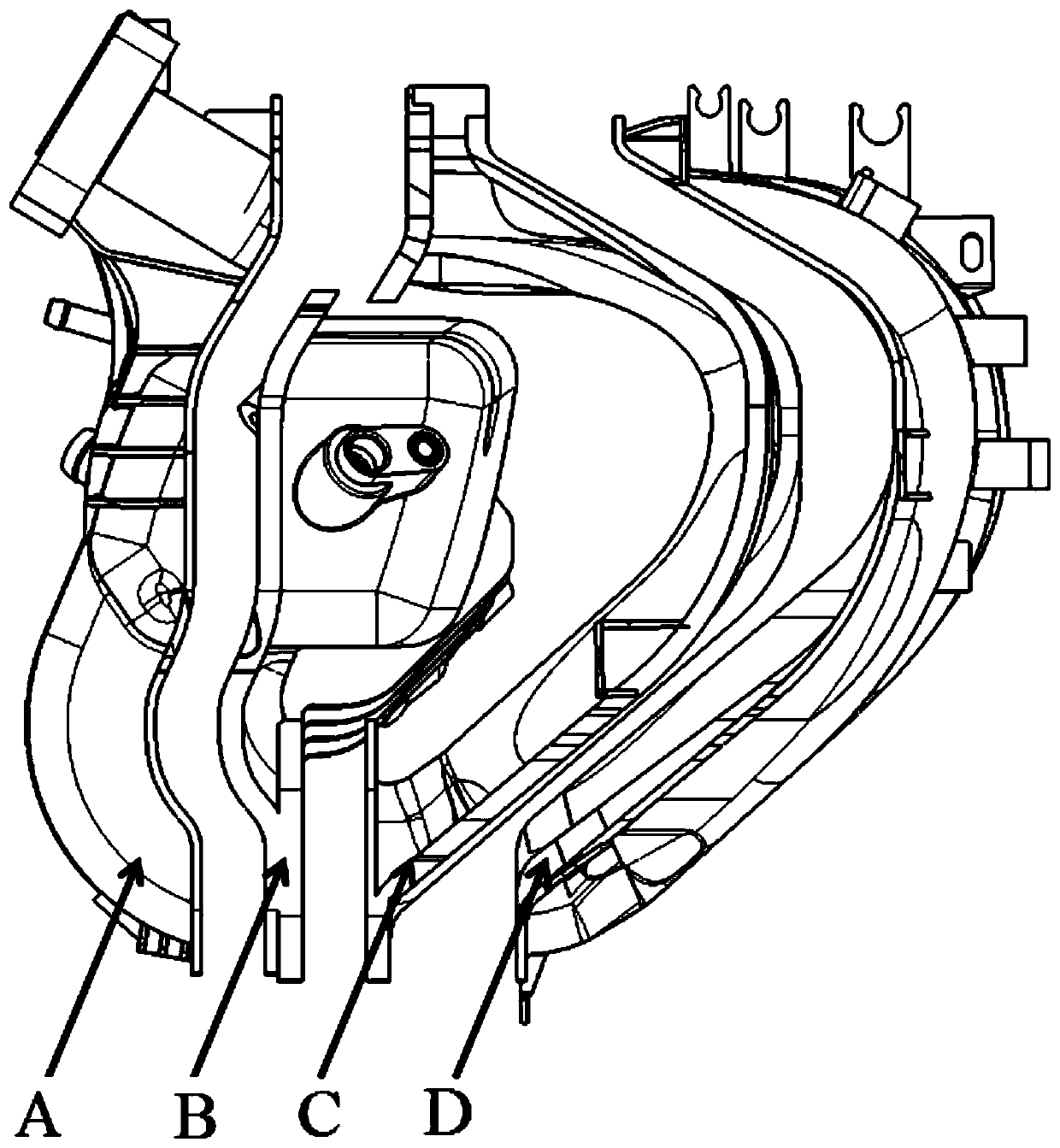

[0022] Please refer to figure 1 and figure 2 , the present invention's optimal plastic intake manifold assembly for naturally aspirated engines comprises a cylinder head flange 1, an intake manifold 2, a pressure stabilizing chamber 3, and a throttle valve flange 4. The fresh air enters the pressure-stabilizing chamber 3 through the throttle valve flange 4, and then flows into each intake channel through the intake ports on the cylinder head flange 1 through four intake manifolds 2. Four fuel injector installation holes 5 are designed on the cylinder head flange 1, and the fuel injectors cooperate with the walls of the fuel injector installation holes 5 through O-rings to realize effective sealing. Since the fuel injector is fixed on the intake manifold 2, the manufacturing complexity of the cylinder head is greatly reduced. Two f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com