Axial plunger type hydraulic pump

A plunger type, hydraulic pump technology, applied in variable capacity pump components, pumps, multi-cylinder pumps, etc., can solve the problems that the sliding shoes do not have automatic compensation function, easy to generate mechanical vibration, serious friction, etc., to improve the use of Life and service performance, simple structure, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a further understanding and understanding of the structural features of the invention and the achieved effects, a detailed description is provided in conjunction with preferred embodiments and accompanying drawings, as follows:

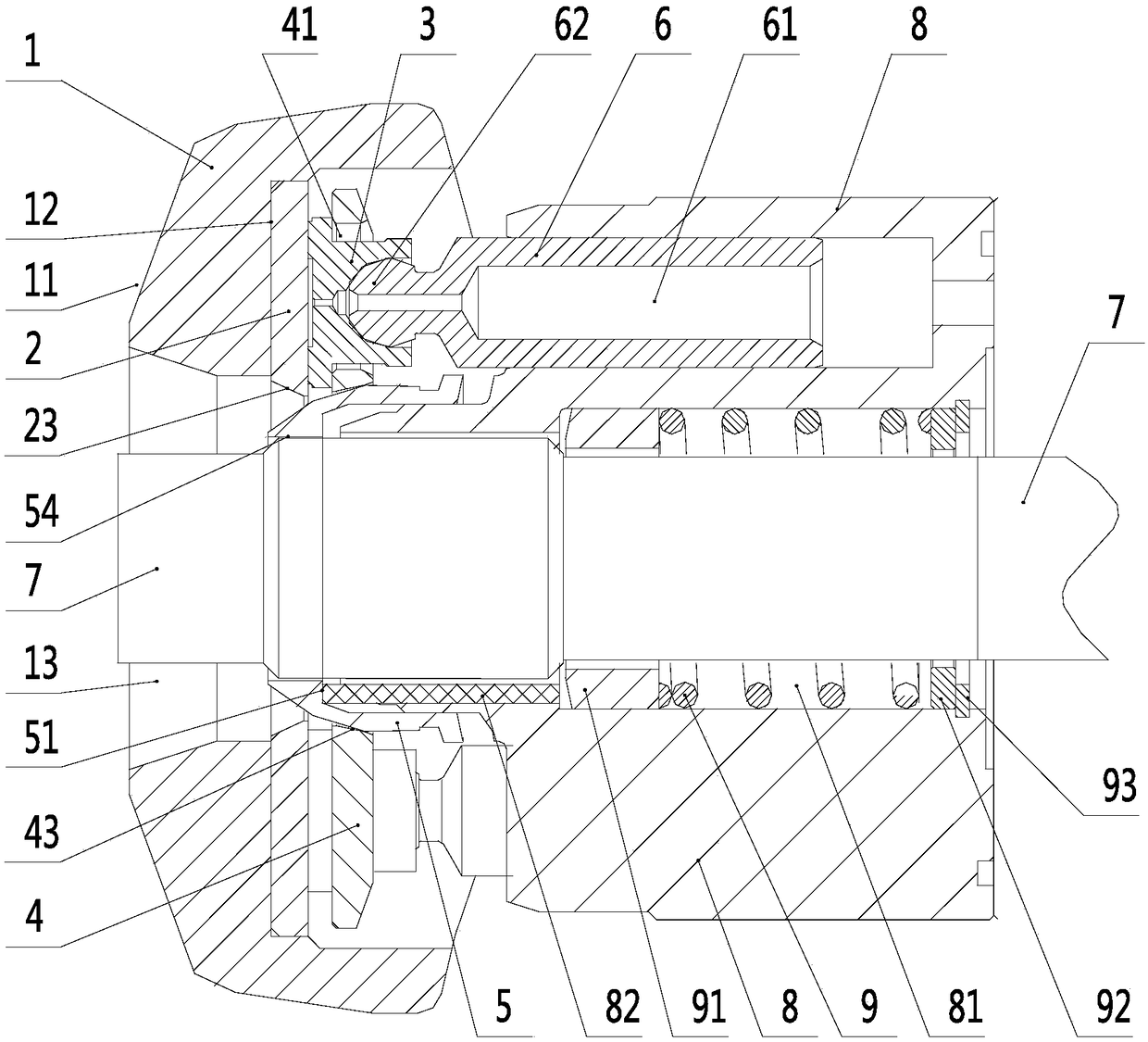

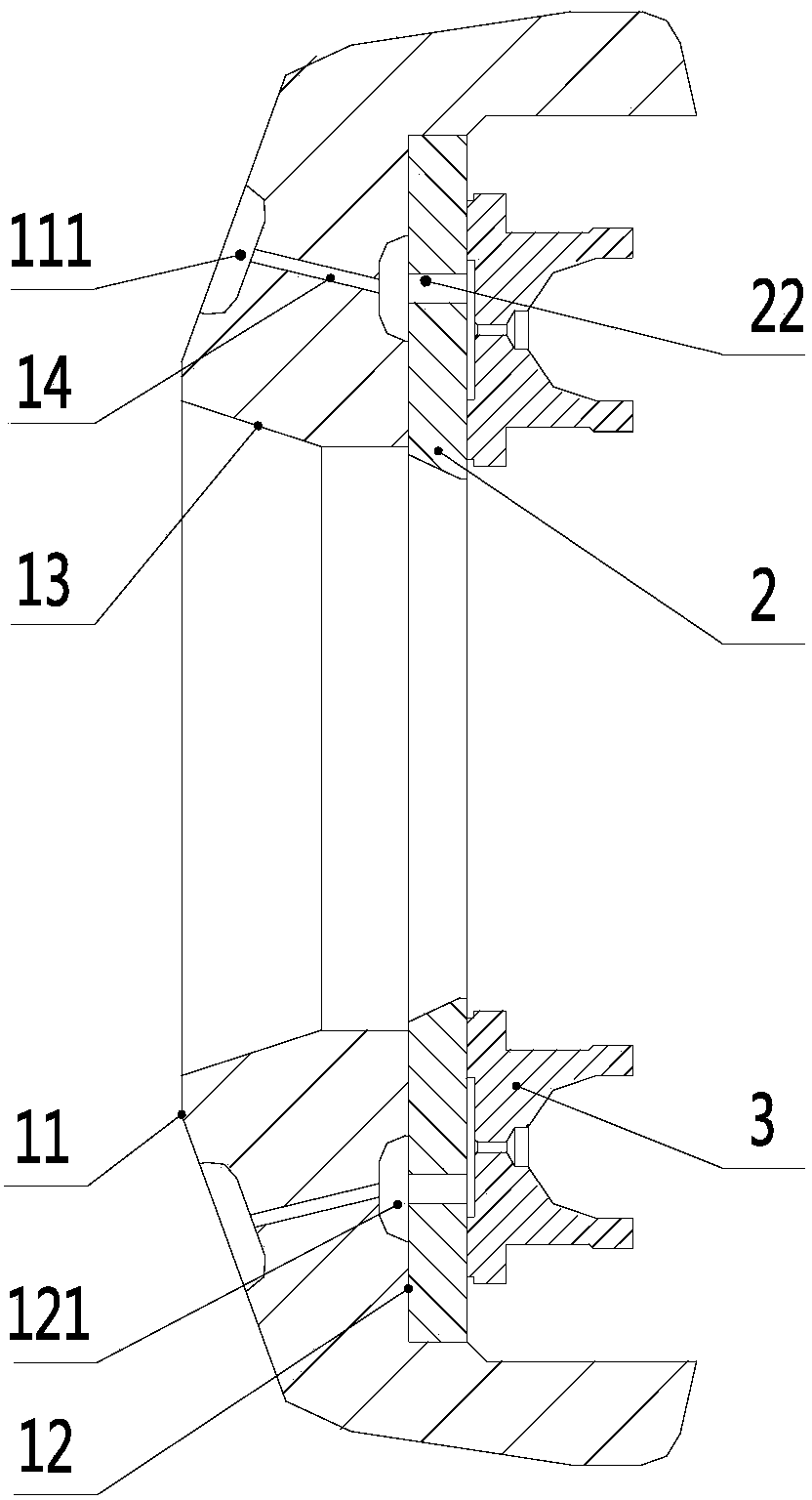

[0035] An axial piston hydraulic pump such as figure 1 As shown, it includes a swash plate 1, a thrust plate 2, a ball joint 5, a rotating shaft 7, a cylinder body 8, a compression pin 82, a spring 9 and a plunger assembly. The plunger assembly includes a plunger 6 and a shoe 3, and the plunger One end of 6 is ball head 62, and slide shoe 3 is wrapped on ball head 62. Sliding shoe 3 is provided with oil shoe oil hole 32, and plunger 6 is also provided with plunger oil hole 61 connected with oil shoe oil hole 32, so that the contact surface of sliding shoe 3 and plunger 6 forms an oil film during operation. Avoid dry rubbing.

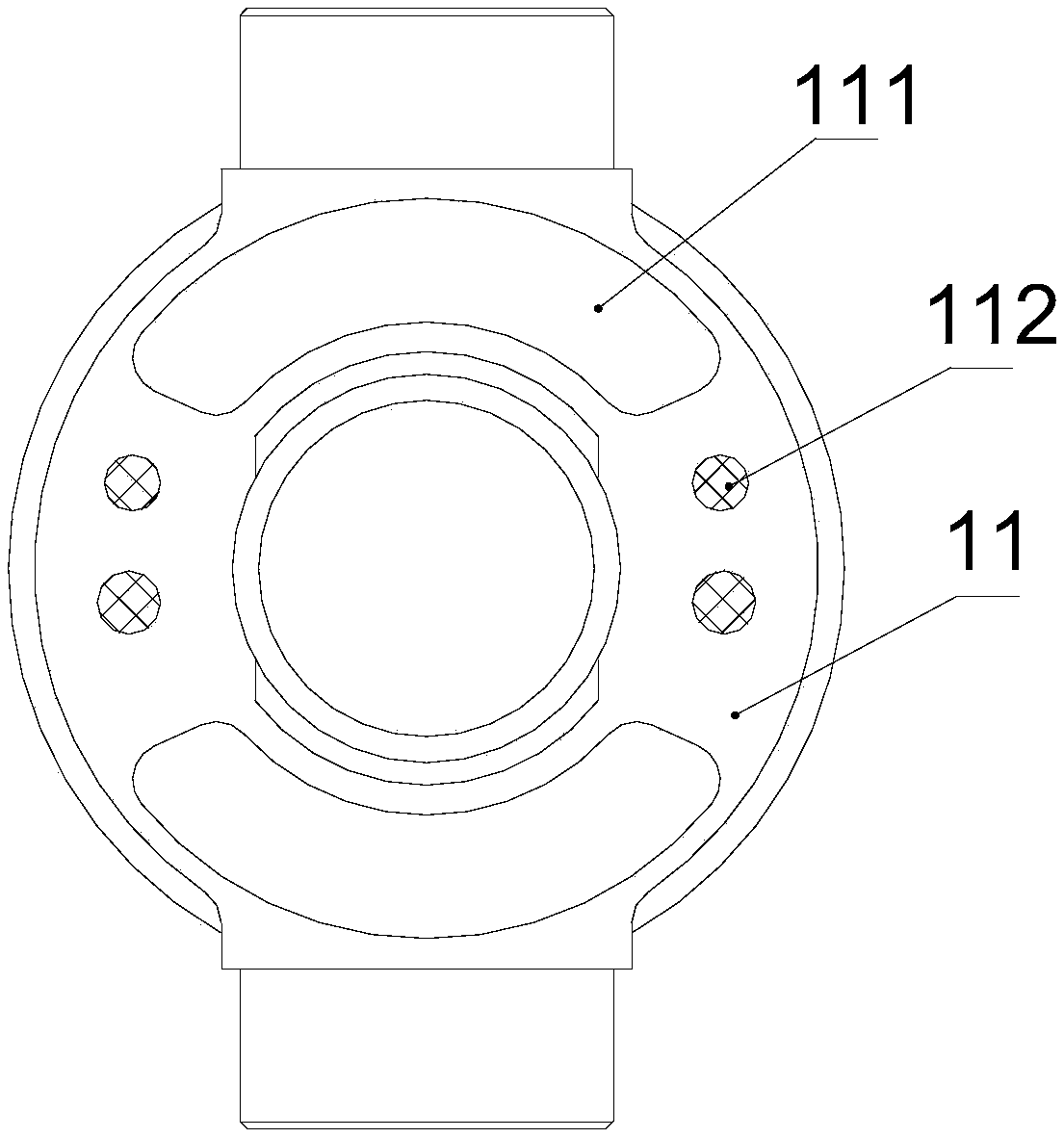

[0036] Such as Figure 1 to Figure 4 As shown, the middle part of the swash plate 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com