Magnetic coil assembly of four-way valve for refrigerating system

A refrigeration system and electromagnetic coil technology, applied in multi-port valves, valve operation/release devices, valve details, etc., can solve the problems that electromagnetic coils do not have heat dissipation function, temperature rise, overload, etc., to achieve light weight, The effect of high foaming rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

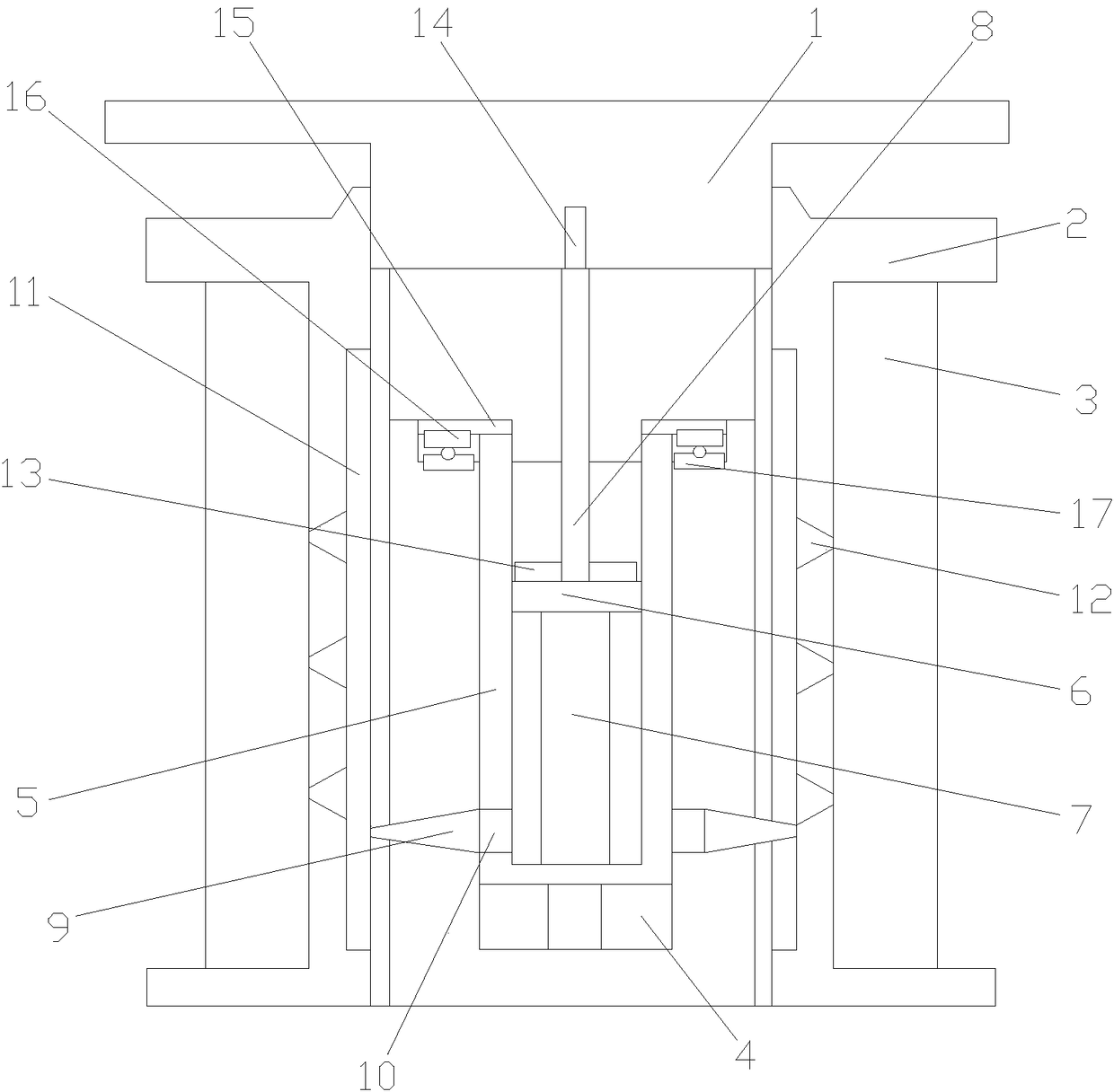

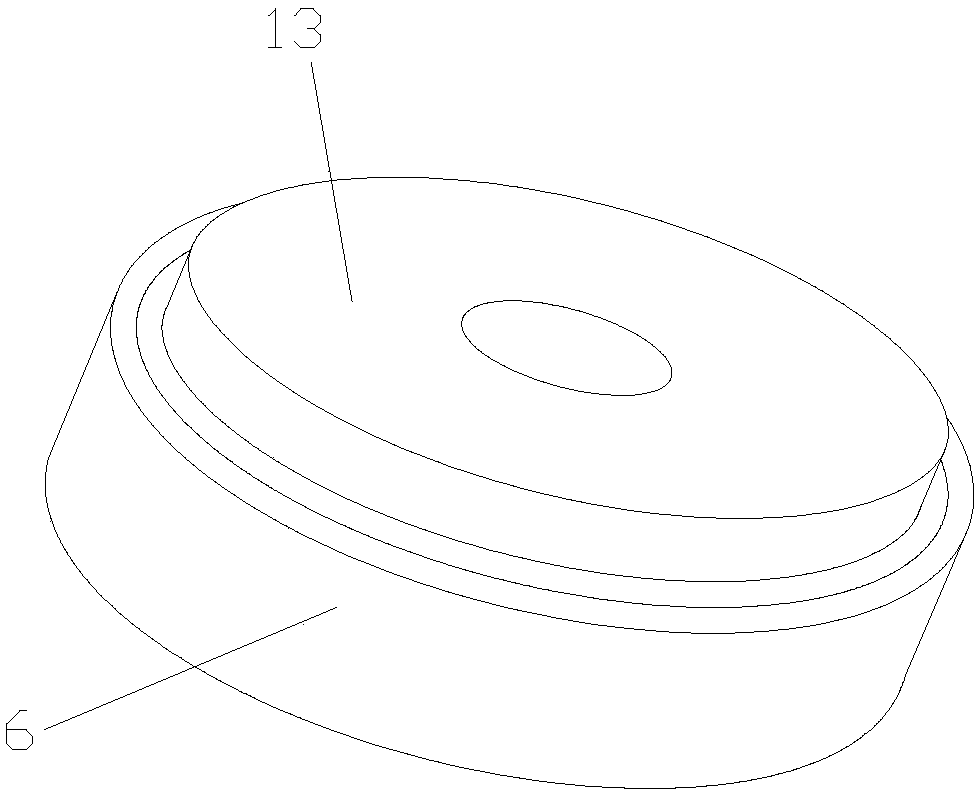

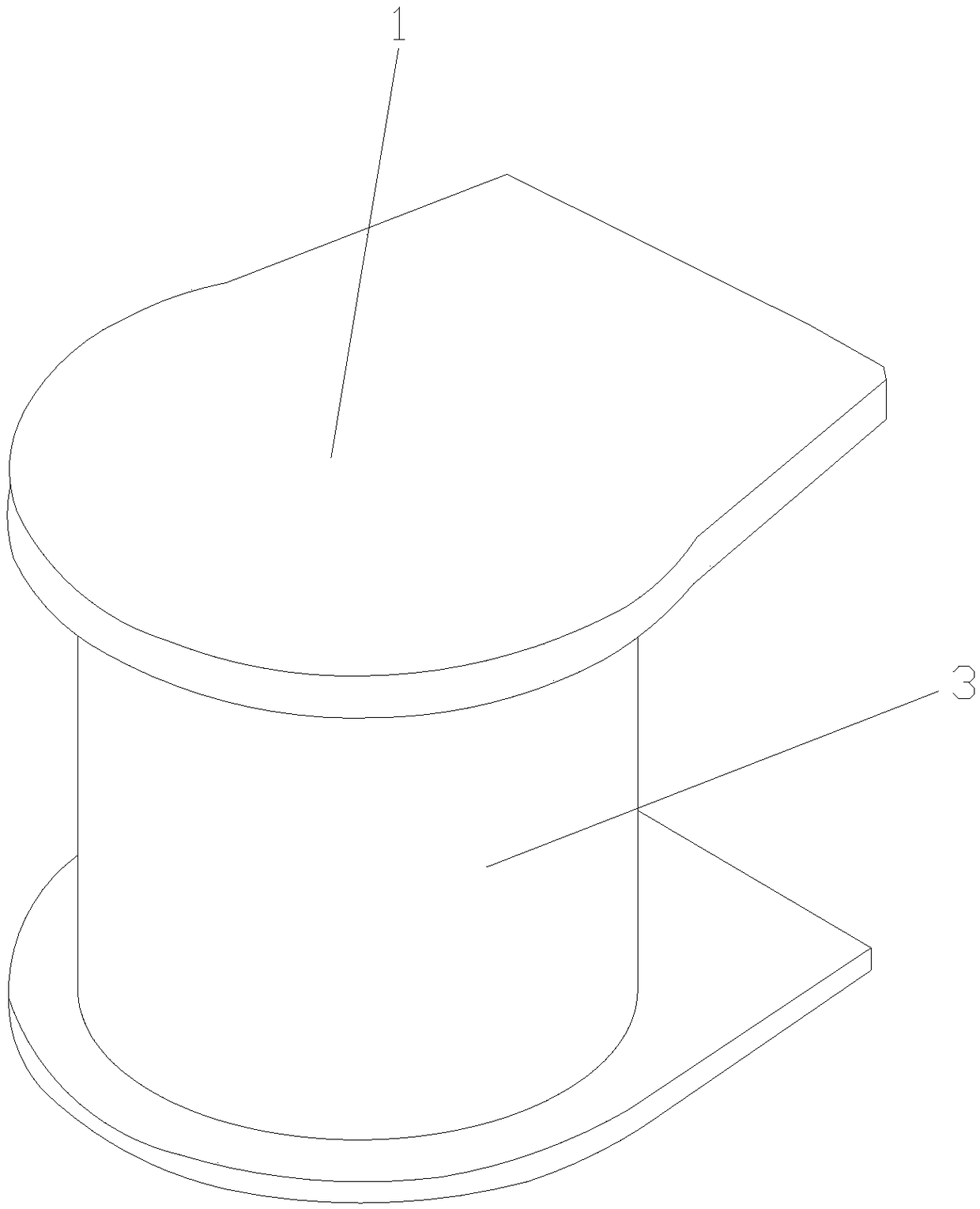

[0044] Such as Figure 1-3 As shown, an electromagnetic coil assembly of a four-way valve used in a refrigeration system includes a valve seat 1 and a valve body 2, a connecting piece is provided between the valve seat 1 and the valve body 2, and the valve seat 1 and the valve body 2 are connected by a connecting piece, the outer periphery of the valve body 2 is provided with a winding 3 that generates electromagnetic force to push the valve body 2 to move after being energized, and the side of the valve body 2 facing the valve seat 1 is provided with a receiving groove 4. The connecting piece is located in the storage tank 4, the connecting piece includes a cylinder 5, a plunger 6, a spring 7 and a connecting rod 8, the plunger 6 and the spring 7 are both located in the cylinder 5, the The back of the plunger 6 and the inner bottom surface of the barrel 5 are respectively fixedly connected to the two ends of the spring 7, one end of the connecting rod 8 is connected to the pl...

Embodiment 2

[0052] Such as Figure 1-3 As shown, an electromagnetic coil assembly of a four-way valve used in a refrigeration system includes a valve seat 1 and a valve body 2, a connecting piece is provided between the valve seat 1 and the valve body 2, and the valve seat 1 and the valve body 2 are connected by a connecting piece, the outer periphery of the valve body 2 is provided with a winding 3 that generates electromagnetic force to push the valve body 2 to move after being energized, and the side of the valve body 2 facing the valve seat 1 is provided with a receiving groove 4. The connecting piece is located in the storage tank 4, the connecting piece includes a cylinder 5, a plunger 6, a spring 7 and a connecting rod 8, the plunger 6 and the spring 7 are both located in the cylinder 5, the The back of the plunger 6 and the inner bottom surface of the barrel 5 are respectively fixedly connected to the two ends of the spring 7, one end of the connecting rod 8 is connected to the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com