Aluminum silicate fiberboard structure with high-strength

A technology of aluminum silicate fiber board and aluminum silicate fiber, which is applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of easy deformation of fiber boards, poor high-strength pressure resistance, heat loss, etc., to offset expansion force, The effect of increasing the strength and increasing the compression area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

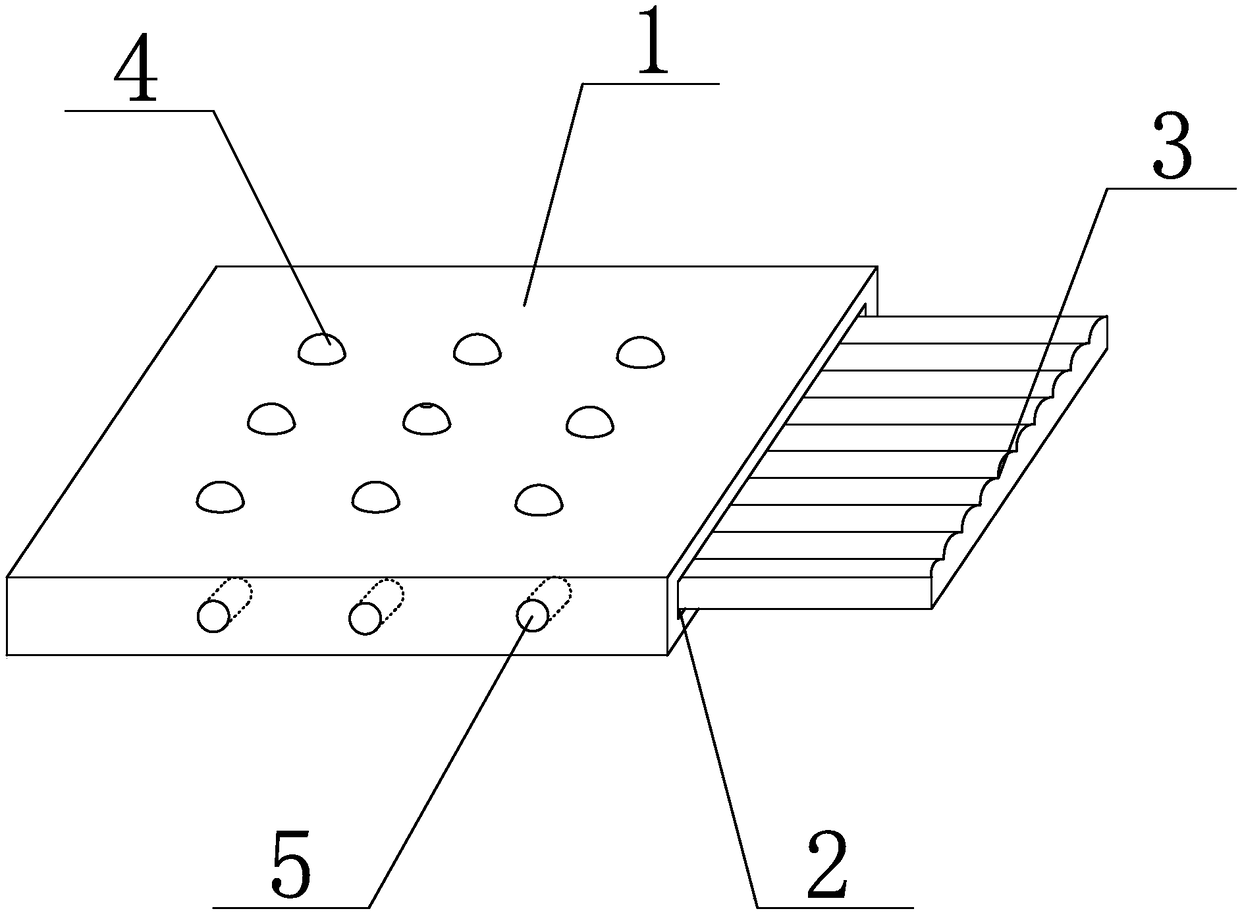

[0021] Such as figure 1 As shown, the present invention has a high-strength aluminum silicate fiber board structure, including an outer plate body 1, two slots 2 are respectively opened at both ends of the outer plate body 1, and an inner plate body 3 is detachably arranged in the slot 2, The upper surface of the inner plate body 3 is corrugated convex, and the inner upper wall surface of the slot 2 is corrugated concave. The positions of the shock-absorbing bumps on the upper surface and the lower surface of 1 are staggered from each other, and one end of the two ends of the outer plate body 1 without slots is connected with an elastic column 5, the elastic column 5 is made of rubber material, and the elastic column 5 One end of the outer plate body 1 is inserted into the end surface of the outer plate body 1 , and the end of the outer plate body 1 opposite to the elastic column 5 is provided with a socket matching the size of the elastic column 5 .

[0022] The aluminum sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com