A method for testing thermal shrinkage of glass

A heat shrinkage and glass technology, which is used in the heat shrinkage test of liquid crystal substrate glass melt samples, and in the field of testing glass heat shrinkage to achieve the effect of fast and accurate testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0023] A method for testing thermal shrinkage of glass, comprising the steps of:

[0024] Step 1: Preparation of Glass Samples

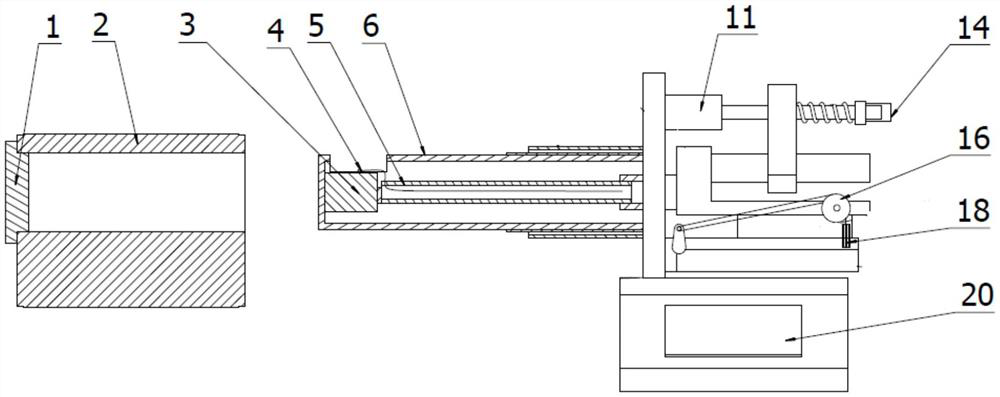

[0025] Process the bulk glass samples melted in the laboratory into a number of cylindrical rods with a length of 50mm and a diameter of ¢8mm. The two ends of the processed glass samples 3 are ground and polished to ensure that the two ends of the glass samples are flat and parallel to each other without burrs. The two end faces installed on the bracket 6 are perpendicular to the axis of the push rod of the dilatometer.

[0026] The second step, glass sample annealing

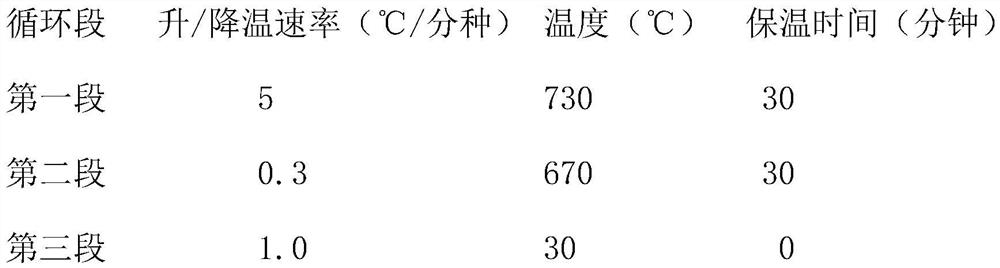

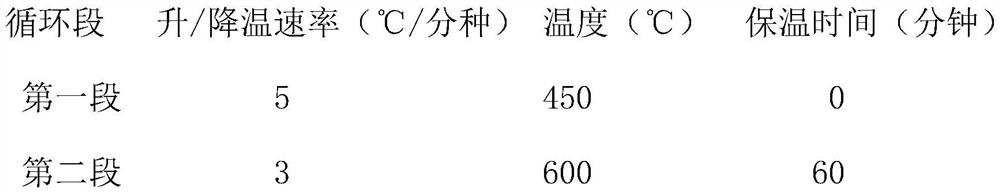

[0027] Place the processed glass sample 3 on the support 6 of the dilatometer. The position of the glass sample 3 cannot affect the normal sliding of the push rod 5 of the dilatometer. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com