Food sterilizing method

A food and microwave sterilization technology, applied in food preservation, food science, application, etc., can solve the problems of high sterilization temperature and long sterilization time in tunnel furnace, and achieve the effect of retaining nutrients, short sterilization time, and good nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A food sterilization method, comprising the following steps:

[0027] S1. After washing 115g of rice with clear water, place it in water and soak for 60 minutes;

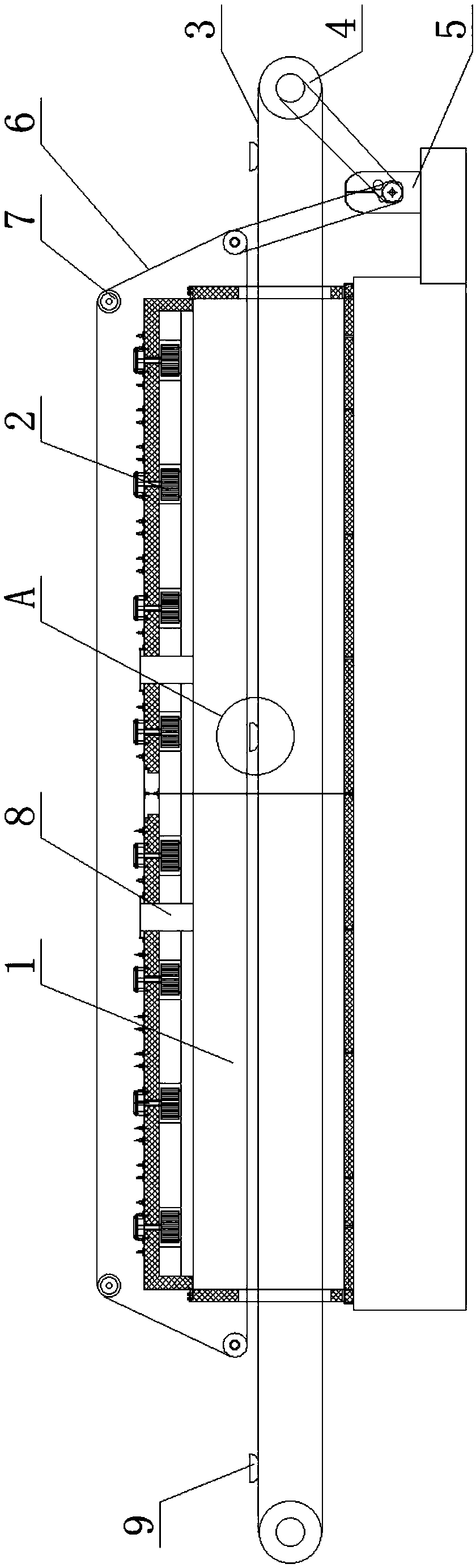

[0028] S2. Pack the soaked rice in a lunch box, and then put the lunch box into figure 1 Microwave irradiation is carried out in the food sterilization equipment shown, the microwave power is 1000W, and the microwave irradiation time is 60s.

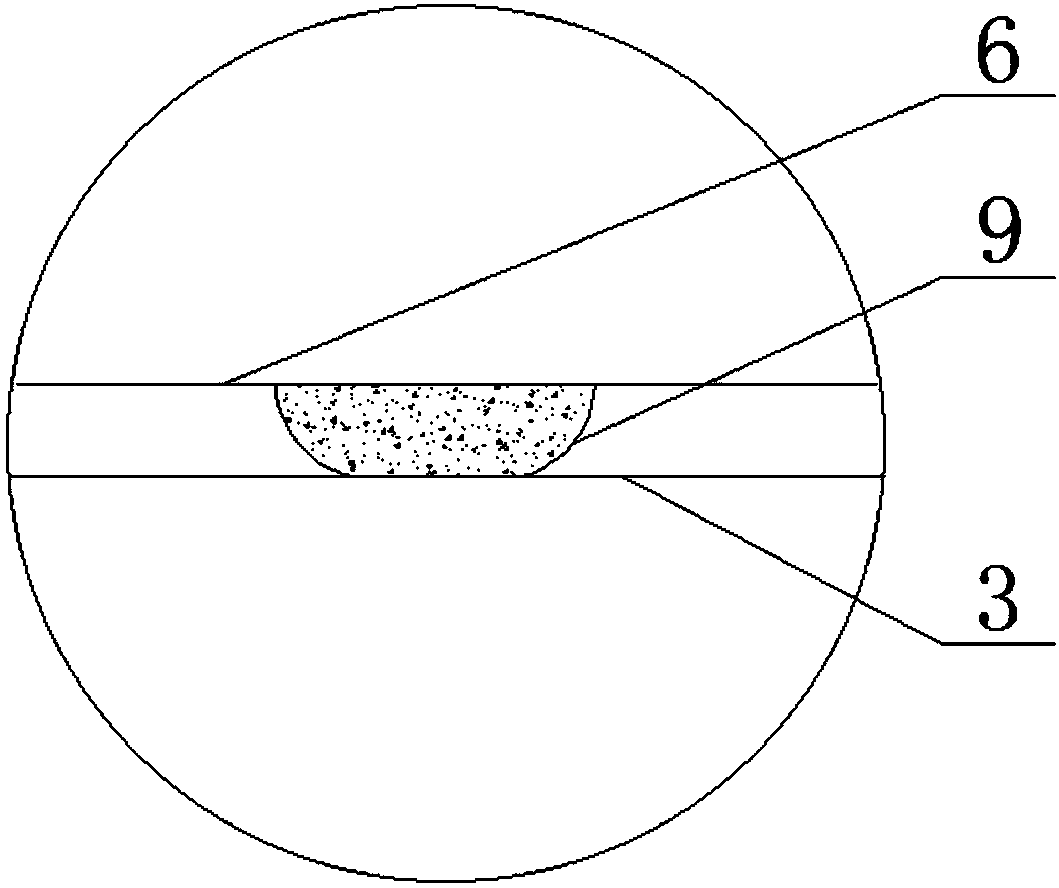

[0029] The above-mentioned food sterilization equipment includes a furnace body 1 and a conveyor belt 3. The furnace body 1 is composed of an inner wall and end covers fixedly connected to the left and right sides of the inner wall. Eight magnetrons 2 are evenly distributed on the upper surface of the inner cavity of the inner wall. The upper surface of the cavity is provided with an air induction pipe 8 . The middle part of the end cover is provided with a through hole, which is convenient for the conveyor belt 3 to pass through.

[0030] The left and right ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com