Cultivation method for mushroom

A planting method and technology of shiitake mushrooms, which are applied in botany equipment and methods, plant cultivation, mushroom cultivation, etc., can solve the problems of increasing the subsequent sterilization process, increasing the production cycle of shiitake mushrooms, and reducing the quality of the culture medium, so as to shorten the planting time , shorten the cooling time, improve the effect of fruiting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Ingredients: The mushroom cultivation medium was prepared from the following raw materials in parts by weight, 70 parts of sawdust, 2 parts of gypsum, 22 parts of wheat bran, and the amount of distilled water added was 50% of the total raw material weight;

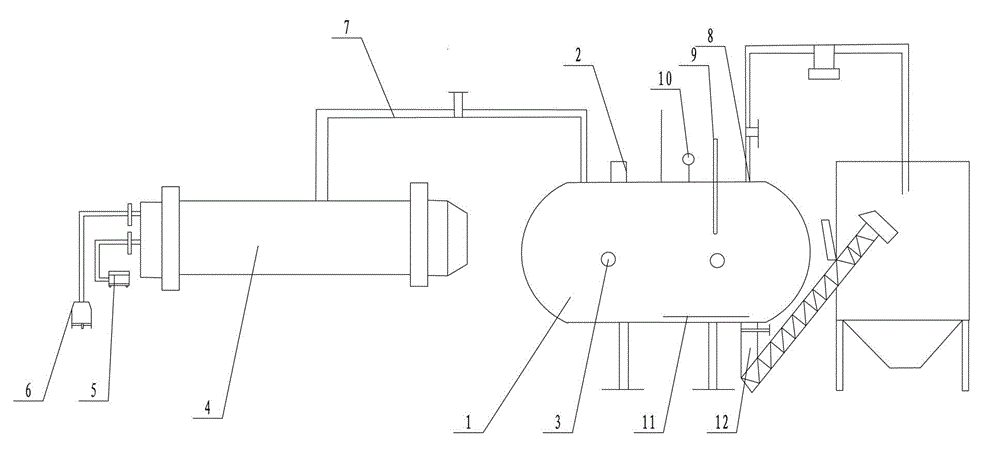

[0020] (2) High-temperature sterilization: Put the culture medium of shiitake mushrooms that has been uniformly mixed in step (1) into a high-temperature stirring tank. The core of the high-temperature stirring tank is the sterilization tank body 1, such as figure 1 As shown, the mushroom cultivation medium enters the sterilizing kettle body 1 through the feed port 2 on the sterilizing kettle body 1, and the steam inlet 3 on the sterilizing kettle body 1 is connected with the external steam pipeline, which is a sterilizing kettle body. The main body 1 provides a heat source, the temperature is set at 121°C, and the pressure is 0.160 MPa. The thermometer 9 and pressure gauge 10 on the sterilizing kettle body 1 can...

Embodiment 2

[0025] (1) Ingredients: The mushroom cultivation medium is prepared by the following raw materials in parts by weight, 80 parts of sawdust, 1 part of gypsum, 15 parts of wheat bran, and the addition of distilled water is 90% of the total raw material weight;

[0026] (2) High-temperature sterilization: put the mixed mushroom culture medium into a high-temperature stirring tank, set the temperature at 126°C, the pressure at 0.155MPa, and the reaction time for 1.5 hours;

[0027] (3) Cooling down: After the sterilized high-temperature stirred tank is completed, it is cooled to 25°C within 1.4 hours; after the high-temperature reactor is stirred, the inside of the high-temperature reactor is evacuated, and then sterile air is introduced, and after 20 Minutes later, the inside of the high-temperature reactor was evacuated again, and then sterile air was introduced, and a cycle was performed every 20 minutes, so that the cycle was repeated 25 times.

[0028] (4) Inoculation: Pour s...

Embodiment 3

[0031] (1) Ingredients: The mushroom cultivation medium was prepared from the following raw materials in parts by weight, 75 parts of sawdust, 1.5 parts of gypsum, 25 parts of wheat bran, and the amount of distilled water added was 60% of the total raw material weight;

[0032] (2) High-temperature sterilization: put the mixed mushroom culture medium into a high-temperature stirring tank, set the temperature at 123°C, the pressure at 0.158MPa, and the reaction time for 2 hours;

[0033] (3) Cooling down: the high-temperature stirred tank after sterilization is cooled to 25°C within 1 hour; after the high-temperature reactor is stirred, the inside of the high-temperature reactor is evacuated, and then sterile air is introduced, and after 10 Minutes later, the high-temperature reactor was evacuated again, and then sterilized air was introduced, and a cycle was performed every 10 minutes, so that the cycle was 50 times.

[0034] (4) Inoculation: Pour solid shiitake mushroom strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com