Fresh-keeping treating method for fresh-wet instant vermicelli

A processing method and technology for vermicelli, which are applied in the field of fresh-keeping treatment of fresh and wet instant vermicelli, can solve the problems of insufficient sterilization effect, easy to swell and break bags, etc., and achieve the effects of improving production efficiency and sterilizing effect, prolonging shelf life, and maintaining clean processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

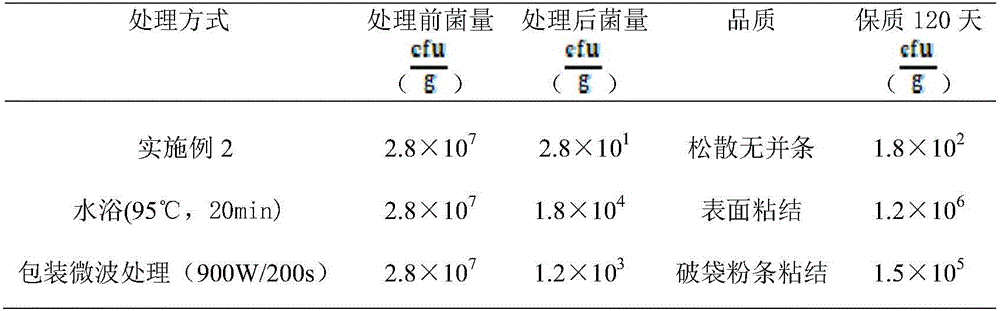

Examples

Embodiment 1

[0031] A fresh-keeping treatment method for fresh and wet instant vermicelli, comprising the steps of:

[0032] (1) Pre-treatment of vermicelli: the rice is washed, crushed, adjusted in humidity, extruded and matured, cut off, and hung on a pole to make fresh and wet rice vermicelli. During the process, ozone sterilization is used for more than 30 minutes. The ozone disinfection is relatively uniform, and there is no dead angle, and the disinfection effect is good. The longer the disinfection time, the better, but in consideration of energy consumption, 30 minutes of disinfection can achieve the goal. The moisture content of the fresh wet vermicelli after the treatment is 45wt%. If the water content is too high, the vermicelli will stick and affect the quality of the finished product. If the water content is too low, the vermicelli will be burnt during subsequent microwave drying, which will also affect the quality of the finished product.

[0033] (2) Bagging: put the rice v...

Embodiment 2

[0039] A fresh-keeping treatment method for fresh and wet instant vermicelli, comprising the steps of:

[0040](1) Pre-treatment of vermicelli: mix sweet potato starch and ingredients into a self-cooked vermicelli machine to extrude and ripen to obtain fresh and wet sweet potato vermicelli. After cutting off the hanging rod, send it to a dynamic temperature-variable freezing workshop for aging treatment for about 40 hours (8 hours between 1 and 5°C) , -1~-6℃ for 14h, -15~-18℃ for 20h), during the vermicelli aging process, use ozone to sterilize for 30 minutes. Send the frozen and aging vermicelli into the room temperature thawing warehouse for strong wind convection to thaw the loose powder naturally. During the thawing period, turn on the ultraviolet germicidal lamp to maintain a low-bacteria environment in the thawing warehouse. The water content of the fresh wet vermicelli after the treatment is 40wt%.

[0041] (2) Bagging: Put the thawed loose sweet potato vermicelli with...

Embodiment 3

[0051] A fresh-keeping treatment method for fresh and wet instant vermicelli, comprising the steps of:

[0052] (1) Vermicelli pre-treatment: Potato starch, cooked Gorgon (i.e. starch gelatinized pulp) and ingredients are mixed with water in the dough mixer, and then sent to the vacuum dough mixer with a vacuum degree of 0.085-0.096 MPa to remove the air in the dough. Reduce broken strands and finished product air bubbles. The degassed dough is put into the powder leaking machine to be formed, and the formed vermicelli is cured in hot water at 90-98°C for 30-50s, cooled in cold water, and then pickled in acid water with a pH of 4.0-5.0 for 30-70s. Take out, cut off the vermicelli and hang it on the pole, blow off the water on the surface of the vermicelli with cold wind to keep the surface of the fresh and wet vermicelli dry, and then send the vermicelli to the dynamic temperature-variable freezing workshop for aging treatment for about 48 hours (1~5℃ for 8 hours, -1~-6 16h d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com